From April 7th to 9th, 2023, Jalon’s 9th Summit Forum on Molecular Sieve Technology and Applications, hosted by Luoyang Jalon Micro-New Materials Co., Ltd, guided by China Industrial Gas Industry Association and China General Machinery Industry Association Gas Separation Equipment Branch, and supported by China Chemical Society Molecular Sieve Professional Committee, was held successfully in Luoyang City, Henan Province, China.

The forum attracted more than 260 guests, including experts and scholars engaged in basic and application research of molecular sieve, upstream and downstream famous enterprises and industry-related news media. With the theme of “Continuous innovation for high quality development of molecular sieve industry”, the forum focused on the key/major issues encountered by molecular sieve-based adsorption and catalytic new materials in the process of contributing to high-quality economic development and discussed from the scientific and technical aspects, promoting the high quality development of the industry. Li Yicheng, Vice General Manager of Sales Company of Jalon, hosted this forum.

Mr. Jiang Ming, Vice President of China General Machinery Industry Association and Chairman of Gas Separation Equipment Branch, delivered a speech.

Mr. Ma Yinchuan, President of China Industrial Gas Industry Association, delivered a speech.

Mr. Li Jianbo, Chairman of Luoyang Jalon Micro-Nano New Material Co., Ltd. delivered the opening speech.

Mr. Ye Zirong, Deputy Director of Hongkou District Investment Promotion Office of Shanghai, made investment promotion.

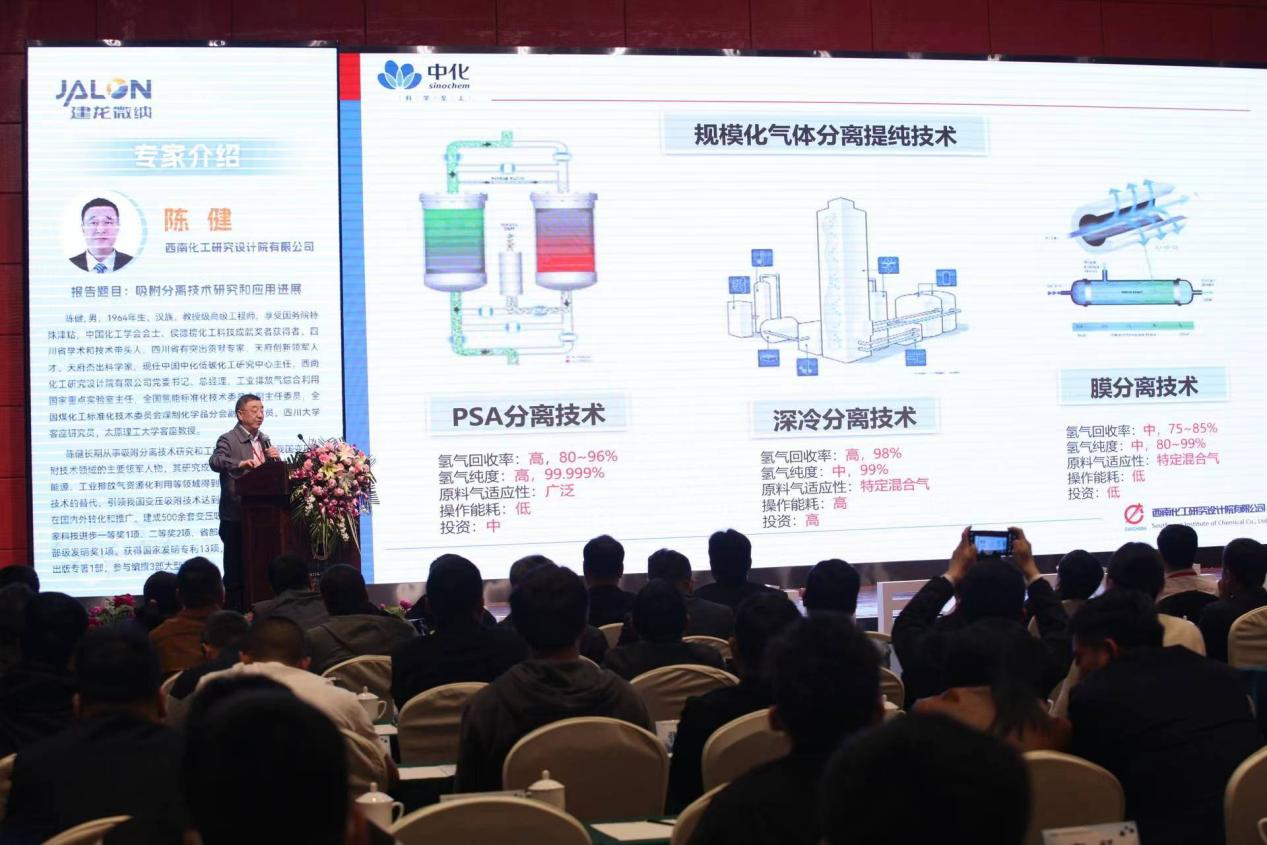

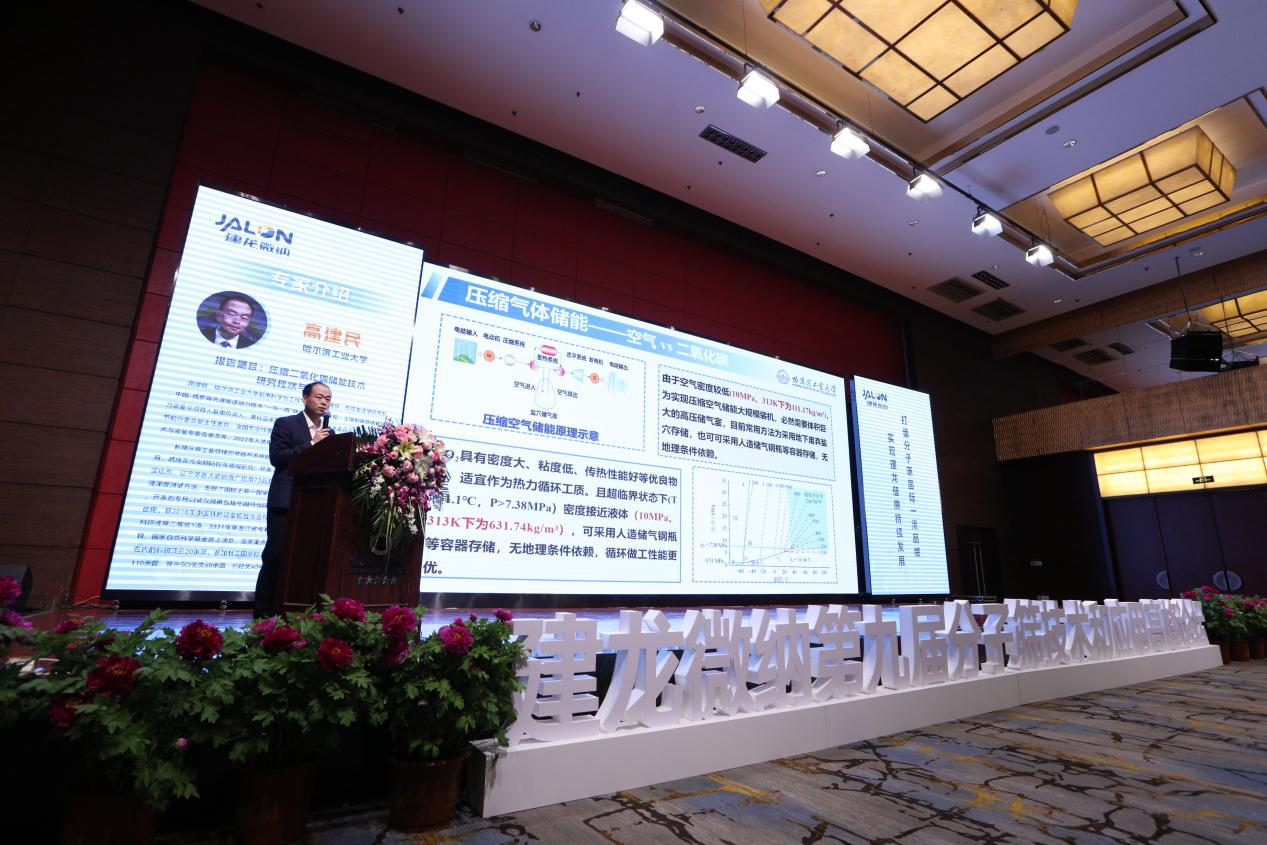

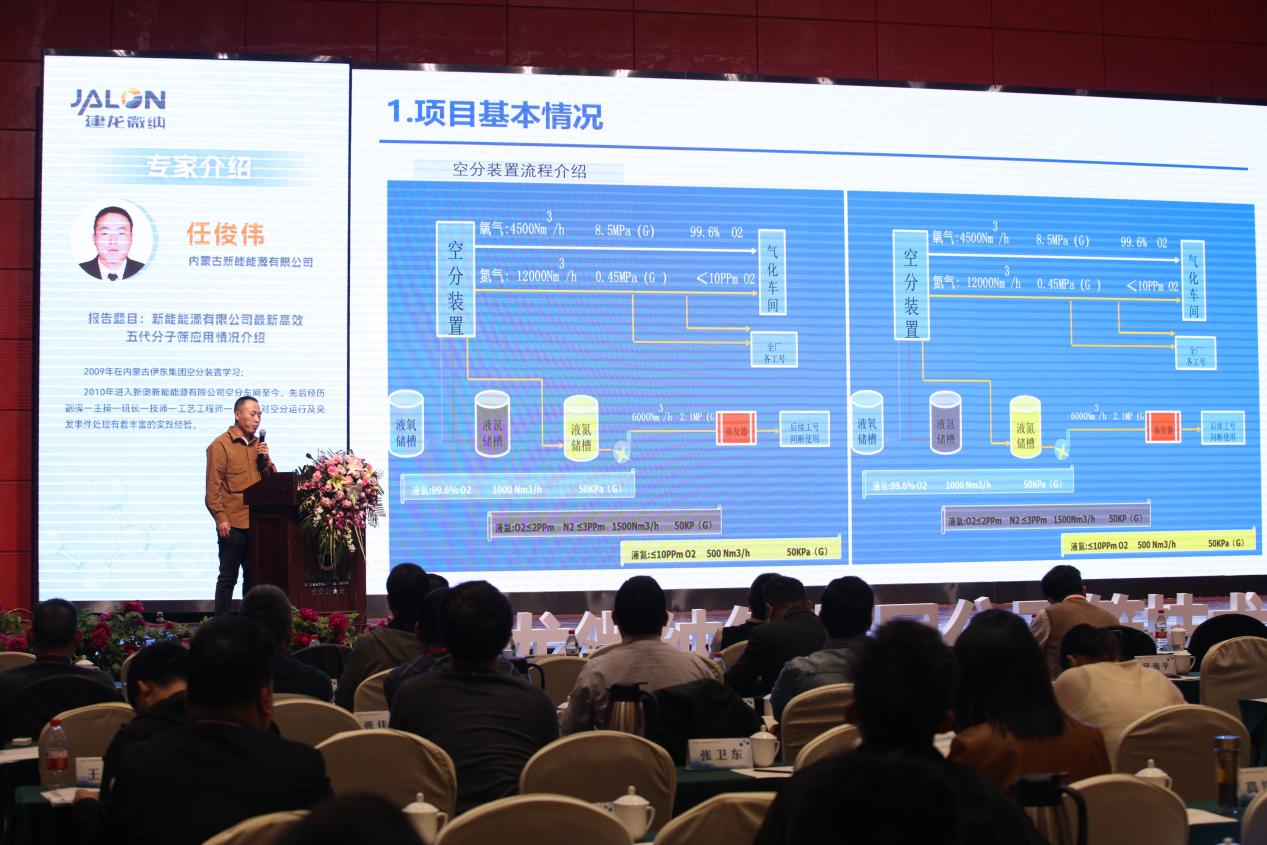

At the forum, Professor Liu Yingshu, Director of the Institute of Gas Separation Engineering of USTB , firstly gave a special report on “Current status of small VPSA oxygen generation technology and development trend in the post-epidemic era”. Mr. Chen Jian, Secretary of the Party Committee and General Manager of Southwest Chemical Research and Design Institute Co. Ltd, Prof. Xiao Fengshou of Zhejiang University, Gao Jianmin, Dean of School of Energy Science and Engineering of Harbin Institute of Technology, Prof. Lu Anhui of Dalian University of Technology, Prof. Yang Jiangfeng of Taiyuan University of Technology, Prof. Zhao Chen of East China Normal University, Prof. Hu Guoping of Ganjiang Innovation Research Institute of Chinese Academy of Sciences, Dr. Bai Pu, Vice President and Chief Technical Officer of Luoyang Jalon Micro-Nano New Materials Co. Ltd., Mr. Ruan Jialin, Chief Engineer of Hangzhou Fortune Gas, Mr. Tu Zhongming, Sales Director of Zhejiang Zhengda, Mr. Ren Junwei from Inner Mongolia New Energy Co., Ltd., Mr. Lei Zhigao from Hunan Iron and Steel Group Liangang Energy Plant, Manager Zhao Jianhao from Beijing Stone Century Technology Co., Ltd., Mr. Li Qiang from MayAir Technology (China) Co., Ltd.., Mr. Wu Haiping, Deputy General Manager of Shanghai Hansi Industrial Co., Ltd., Duan Hongchang, Senior Engineer of CNPC Lanzhou Chemical Research Center, 18 experts stayed on the theme of promoting the high-quality development of molecular sieve industry and made wonderful reports on the latest research results and new application scenarios in the field of molecular sieve.

At the scene of the forum, the attendees discussed deeply and shared opinions on Jalon’s new product and the reports of the experts.

On April 9th, the guests visited Jalon Technology Innovation Center (under construction) and Jalon Adsorbent Materials Industrial District to learn more about Jalon’s business development, industrial layout and corporate culture construction. This forum coincided with the 20th anniversary celebration of the completion of Jalon’s molecular sieve project. At the appreciation dinner, an award ceremony was held for the 20th anniversary of the completion of Jalon Molecular Sieve Project. Mr. Li Jianbo, Chairman of Jalon, awarded gold medals to 18 employees who have worked for Jalon for 20 years, expressing his gratitude for their 20-year of dedication and devotion.

In 2003, Jalon’s first production line of molecular sieve powder was launched and put into production. In the past 20 years, Jalon has always adhered to the corporate mission of “science and technology to promote enterprises, industry to serve the country”, insisted on innovation-driven and science and technology-led, deeply implemented the “diversification, quality, brand strategy”, “from absorption to catalyst strategy” and “internationalization strategy”. Jalon has been focusing on its specialized field, deepening its main business, and continuously promoting molecular sieve technology innovation and industrial upgrading, from the initial “follower” to the “leader” in molecular sieve industry. Jalon has achieved import substitution with domestic products in many applications and made remarkable develpment results.

As a leading enterprise in the molecular sieve industry, Jalon has the responsibility to make greater contributions to the development of the field. The successful holding of the summit forum promotes the deep cooperation development and technical progress of molecular sieve industry, solidifies the foundation for accelerating industrial transformation and upgrading, and continuously expands the application field of molecular sieve, which contributes to promoting the high-quality development of molecular sieve industry.