When industrially separating gas mixtures that can absorb gas, the adsorption operation has significant advantages. At present, due to the development of adsorption technology and the emergence of new adsorbents, the adsorption process is used in cryogenic air separation units and atmospheric pressure swing adsorption air to produce oxygen and produce The application of nitrogen equipment has become a routine choice. In cryogenic air separation, molecular sieve adsorbers are used in air purification systems, so that carbon dioxide in the air is less than 1 ppm, and water is less than 5 ppm. The process of using molecular sieve to produce oxygen and nitrogen from the air by pressure swing adsorption at room temperature has also become another air separation device.

According to the size of the cryogenic air separation unit, it can be divided into vertical radial flow adsorber and horizontal radial flow adsorber.

1. Schematic diagram of horizontal radial flow molecular sieve adsorber:

The adsorbent of the horizontal molecular sieve is loaded through the upper manholes at both ends, the lower layer is alumina to remove moisture from the air, and the upper layer is molecular sieve to remove carbon dioxide, acetylene and other hydrocarbons, and the middle is separated by a partition. The molecular sieve air outlet pipe is equipped with a gas distributor and a dust filter cartridge, and the air inlet pipe is equipped with a gas uniformly distributed baffle.

Advantages: mature technology, simple structure and process design, easy maintenance.

Disadvantages: large floor area, large working resistance, slow flow rate, uneven air distribution, high energy consumption.

2. Schematic diagram of vertical radial flow molecular sieve adsorber:

The vertical adsorber is composed of an outer shell, three-layer grid and a central tube. The activated alumina is installed in the interlayer between the outer grid and the middle grid, and the molecular sieve is installed in the interlayer between the middle grid and the inner grid. , The weight of all alumina and molecular sieves is supported by a three-layer grid suspended on the upper head. The upper part of the cylinder is equipped with a charging tube for filling alumina and molecular sieves.

When the purifier is working, the air enters from the bottom, first passes through the alumina layer to remove the moisture in the air, then passes through the molecular sieve layer to remove carbon dioxide, acetylene and other hydrocarbons, and is discharged from the top of the container through the filter.

When the purifier is regenerated, the polluted nitrogen from the cold box enters from the top of the container and is discharged from the bottom, in the opposite direction to that of adsorption. The central cylinder not only functions as a filter, but the special structure at the center can ensure that the forward air or regenerated backflow air has the same gas velocity in each section, so that the adsorption speed and adsorption capacity of each part of the adsorption bed along the axial direction are uniform. , The adsorption saturation time is the same.

Advantages: uniform air distribution, small footprint, small resistance, fast flow rate, and low energy consumption.

Disadvantages: complex structure, complicated process design, high manufacturing cost, and difficult maintenance.

Because of the adsorption performance of 13X molecular sieve, can be a long period of water and carbon dioxide adsorption in the air, its adsorption belongs to the balance separation type.

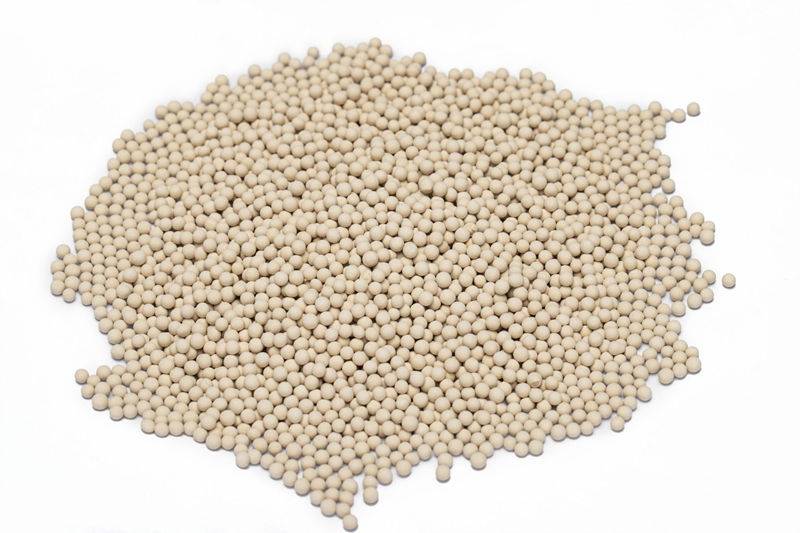

Jalon’s JLPM series molecular sieves are mainly used for cryogenic drying of general industrial gases. The purification system in the air separation unit removes H2O and CO2, as well as natural gas and other hydrocarbon desulfurization (removal of H2S and mercaptans) and CO2.

It is worth mentioning that North Copper Co. LTD, Yuanqu Smelter overhaul air separation unit using high efficiency molecular sieve, activated alumina projects use Jianlong JLPM fifth-generation cryogenic air separation molecular sieve. The equipment molecular sieve was replaced on April 12th, 2020, and it was put into operation on April 26th. From May 5th to May 8th after 72 hours of full-load operation, the CO2 at the outlet of the molecular sieve adsorber is stable at 0.2-0.3ppm, which meets the customer’s requirements for CO2 ≤1ppm. The adsorption cycle is extended from 4 hours to 8 hours, so that the number of molecular sieve adsorber regenerations is reduced from 6 to 3, which not only extends the service life of equipment valves and molecular sieve, but also reduces the power load, and has a significant energy saving effect.

Jalon fifth-generation high-performance molecular sieve JLPM is an X-crystal molecular sieve suitable for air pre-purification devices. It not only can efficiently adsorb CO2 and water vapor, but also has good dynamic characteristics and physical characteristics. Under standard process conditions, JLPM usually works synergistically with alumina and has a very high adsorption capacity for water vapor and CO2 . Instead of 13X molecular sieve, the adsorption cycle can be doubled after optimized filling.

Otherwise, The fifth-generation high-performance molecular sieve JLPM will bring multiple benefits to air separation designers and air separation operators. For the design of new air separation units, the application of JLPM can make the area of air separation smaller, thereby reducing equipment investment and operating costs; for the transformation of old equipment, the replacement of JLPM molecular sieve can reduce energy consumption and extend the service life of equipment.