At JALON, we set up a professionally-equipped lab to meet the international mainstream product analysis and testing requirements. Moreover, we can also order corresponding testing equipment to meet the actual application needs of customers, and improve our own capabilities to better serve our customers.

In this way, all materials, samples and finished products are analyzed and certified against specifications at our own lab where we can use test methods according to international norms and have also developed proprietary test procedures specific to your applications to ensure our products give the expected performance.

For each 5 tons of raw materials, we will take less than 13 samples at random, the total weight of which should be no less than 1 kg.

All the raw material samples will be divided into two equal parts, one of which is kept as a retained sample, and the other one is analyzed according to our standard tests;

We take the arithmetic mean of the parallel measurement values as the report result, and the absolute value difference between the two measurement results should be under 0.4%.

When exposed to cold and moist conditions, the molecular sieve is easily cracked after being calcined in a roaster. Therefore, we pay close attention to take protective actions at production, especially in the winter.

By equipping a reliable venting system, we can keep the roasting furnace at good condition for production, and by conducting strict tests on the unfinished products at every stage, we can ensure that the final products are qualified.

All analysis results will be compared with our quality standard as well as the standards provided by clients to meet their application requirements, and sent to clients as a quality warranty document.

After the samples are analyzed as required, we will keep 200 g samples from each batch material for a period of three years for traceability.

To ensure that the indicators of the intermediate product are stable and uniform, the seed should be added continuously and quantitatively.

According to the temperature change, we adjust the flow of cooling circulating water and speed of machine to ensure high compressive strength, less dust.

By timely machinery inspection and maintenance, we can adjust the speed and angle of machines to avoid the impact of mechanical loss on bulk density (g / ml).

By quickly packing under the condition of low air humidity (humidity <50%), we can avoid the water absorption during packing to keep lowest moisture content.

Intelligent Particle Strength Tester

Dynamic Mixer

Constant Temperature Stirring Reactor

Gas Chromatograph

Hiden Gas Analysis System

X-Ray Detector

Laser Particle Size Analysizer

Particle Abrasion Tester

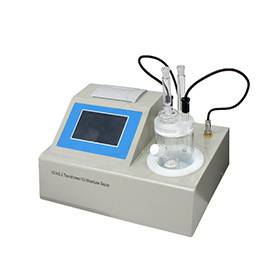

Carl Fisher Moisture Detector

Micromeritics Surface Area And Porosity

Loss on attritio

30Nm3/h PSA/VPSA Pilot test unit

Get inspired by our optimal solutions for various industrial applications.