Introduction to Desiccants

What Are Desiccants?

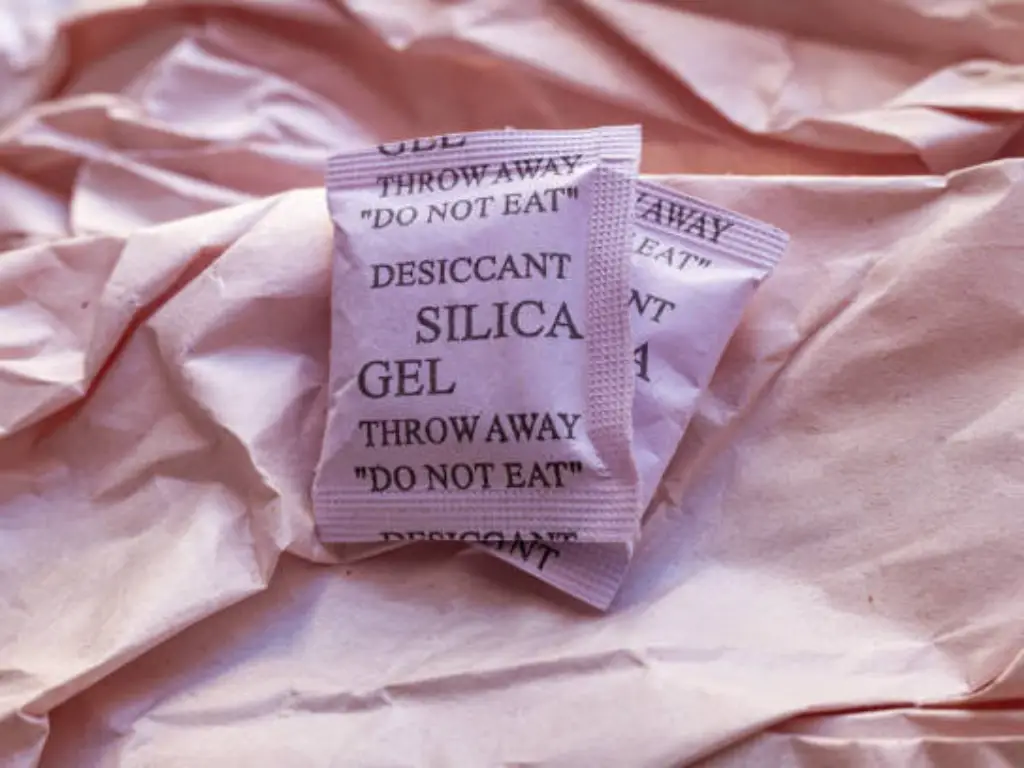

Desiccants are materials that are used to remove moisture from their immediate environment or surroundings. These moisture absorbing materials are very important in ensuring that products do not get damaged due to high humidity. You might have come across small packets of silica gel in new shoe boxes or electronic products packaging. These small packets are good examples of desiccants, which do not rest until they ensure that the contents are as dry as possible. While desiccants are available in many forms, the common one is the silica gel packs, but there are others such as the molecular sieves and activated alumina, which have different characteristics that make them suitable for use in various industries.

How do Desiccants Work?

Desiccants work by adsorbing moisture from the surrounding air through the use of a surface that has a high affinity for water molecules. This process is referred to as adsorption whereby water molecules adhere to the surface of the desiccant material. In the case of desiccants, this moisture absorption can be either physical or chemical in nature depending on the type of desiccant being used. Desiccants are useful in preserving sensitive materials from the effects of moisture such as rusting, molding, mildewing and other related effects of moisture. The result? They do not get damaged by humidity whether high or low and are able to maintain their functions.

Desiccants are not just about ensuring that products are dry; they play a vital role in preserving the quality and safety of numerous products in different industries. They cannot be overemphasized because they help to maintain products in the best condition possible throughout the usage cycle regardless of the prevailing conditions.

Different Types of Desiccants and Their Properties

Silica Gel: The Most Common Desiccant

Silica gel is probably the most popular desiccant of all the types of desiccants available in the market. It is usually packed in small bags with labels that read ‘Do Not Swallow’ and can be found in shoe boxes, electronic gadgets among others. Silica gel beads are excellent moisture absorbers and can be used to prevent moisture from getting to certain items. These beads are suitable for use in different conditions and can be recycled after they have become saturated with moisture, making them a good choice for humidity regulation. For instance, placing silica packet desiccant packets inside an airtight container can help protect important documents from much moisture damage. Similarly, using silica beads in a jewelry box can keep your precious items dry and free from tarnish.

Molecular Sieve: Precision Moisture Control

Molecular sieves are synthetic zeolites intended for accurate regulation of moisture content in a system. They possess a regular pore size distribution which enables them to selectively adsorb molecules of a particular size. Due to this high selectivity, molecular sieves are well suited for use in applications where the level of moisture must be tightly controlled, for example in the chemical and pharmaceutical industries. This makes them unique from other desiccants since they are capable of maintaining low humidity even under unfavourable conditions.

Zeolite Powder: Natural Moisture Absorber

Another type of desiccant is the natural mineral called zeolite powder in the form of a powder. It has a microporous structure which enables it to have a high surface area for water and other small molecules to be adsorbed. In certain applications, natural desiccants like zeolites are preferred due to their effectiveness in various industries including agriculture and the environment. They are capable of retaining moisture and thus can inhibit the formation of mold and mildew hence protecting the products.

Activated Alumina: Versatile and Effective

Activated alumina is a type of aluminum oxide that has a porous structure and is widely used for its moisture adsorption properties. It is widely applied in many industries such as water treatment and gas drying. Activated alumina has high thermal stability and has a high adsorption capacity for moisture, which makes it suitable for use in harsh conditions.

Bentonite Clay: Cost-Effective Solution

Bentonite clay is a relatively cheap desiccant that is commonly employed in packaging to prevent moisture accumulation. This natural clay has the ability to absorb moisture at a very fast rate and to a very high capacity. It is especially important for uses where cost is a significant factor and where high performance is needed, for example in packaging foodstuffs and medicines. Bentonite clay assists in the prevention of caking and spoiling of products that are sensitive to moisture.

Calcium Chloride: High Capacity Moisture Absorption

Calcium chloride is also famous for its ability to absorb moisture to a very large extent. It is commonly applied in cases where a lot of water needs to be extracted in a short time, for instance, in cases of flooding and in industries. Calcium chloride has the ability to absorb more moisture than other desiccants, making it a strong choice for managing humidity in different settings.

| Desiccant Type | Material | Properties | Typical Applications |

| Silica Gel | Silicon Dioxide | High capacity, good reusability, moderate selectivity | Food packaging, electronics packaging, pharmaceuticals |

| Molecular Sieve | Synthetic Zeolite | High selectivity, good for low humidity, can be regenerated | Air separation, gas purification, chemical drying |

| Zeolite Powder | Natural Mineral | High surface area, good for moisture control | Agriculture, environmental control, storage |

| Activated Alumina | Aluminum Oxide | High capacity, heat resistant, good for harsh environments | Water treatment, gas drying, industrial drying |

| Bentonite Clay | Clay Mineral | Cost-effective, fast absorption | Food packaging, pharmaceuticals packaging, bulky cargo protection |

| Calcium Chloride | Salt | Very high capacity, fast absorption | Flood remediation, industrial drying (high moisture environments) |

Protecting Food and Electronics in Packaging

Keeping Food Products Dry and Fresh

Silica gel and calcium chloride are some of the most common desiccants that are used in food preservation to ensure that the food does not get spoiled due to moisture. For example, small packets containing silica gel can be found in the packaging of spices, snacks, and dried fruits to reduce the humidity level and thus, inhibit mold formation and product spoilage. Calcium chloride is a chemical that is known to have a very high moisture absorption capacity, and therefore, is suitable for use in packaging that requires very low relative humidity to be maintained in order to keep the packaged food products crisp and fresh for as long as possible.

Preserving Electronics from Humidity Damage

Moisture is a very big enemy of electronics since it leads to corrosion and formation of short circuits. Silica gel and molecular sieves are used in packaging to prevent damage to gadgets like smartphones, cameras, and computers. For instance, silica gel packets are used in boxes of electronic devices to help in absorbing excess moisture that may find its way into the box during transportation or storage. In humid environments, silica gel uses extend to preventing the growth of mold and protecting against excess water in various types of materials. Molecular sieves are used in more specialized applications where it is necessary to maintain a particular level of humidity, so that the expensive electronic components do not become rusty and non-functional. In commercial products such as a cell phone, desiccant packs are essential in ensuring the device remains operational even in humid areas.

Ensuring Safe Transport and Storage

During transportation and storage, desiccants such as activated alumina and silica gel are used to minimize the formation of rust on metal parts. Activated alumina is widely applied in the automotive and machinery industries to prevent metal parts from corrosion due to humidity. These industries put desiccant bags in the shipping containers or packages to guarantee that gears, bearings, and tools do not rust and are fit for use when they are received.

Containers are subjected to fluctuating humidity conditions, which results in condensation and moisture accumulation. Some of the common desiccants that are used to ensure that the inside of these containers remain dry include calcium chloride and bentonite clay. Calcium chloride is especially useful because of its ability to absorb moisture, which can be very useful in maritime shipping where humidity is usually high. Bentonite clay is relatively cheap and is also used to cover goods that may take long periods in transit.

Pharmaceutical Applications

In the pharmaceutical industry, desiccants such as silica gel and molecular sieves are applied to prevent the deterioration of drugs by regulating the humidity level within the packaging. For example, small packets containing silica gel are put inside bottles containing pills and capsules to reduce the effect of moisture on the active ingredients. Molecular sieves are employed in the packaging of sensitive drugs that require low moisture content since the sieves can accurately regulate the amount of moisture in the packaging environment.

Moisture is usually an issue of concern when it comes to medical devices since it can compromise their performance and safety. These devices are protected during storage and transport with desiccants such as activated alumina and silica gel. Activated alumina, which has a very high moisture adsorption capacity, is especially beneficial in protecting electronic medical equipment from moisture damage. Desiccants help in maintaining the dryness of the surrounding environment and thus do not allow moisture to cause damages like corrosion and degradation of the components. This helps to ensure that the medical devices are dependable and functional when the need arises.

Chemical Industry Uses

Preserving Reactive Chemical Compounds

In the chemical industry, desiccants such as molecular sieves and activated alumina are employed to protect reactive chemical substances that are susceptible to the effects of moisture. Molecular sieves are particularly effective because they can selectively adsorb water molecules and therefore are useful for stabilizing chemicals that are sensitive to moisture. Activated alumina is also used to maintain the stability and shelf life of moisture-sensitive products during storage and transportation.

Humidity Management in Laboratory Environments

Desiccants are crucial in laboratories where the moisture content needs to be controlled to the desired level in order to yield accurate results of experiments and analysis. Silica gel and molecular sieves are employed in desiccators and storage cabinets to protect equipment and material from harm. For example, silica packs are employed in desiccators to create the right conditions for storing hygroscopic substances and to avoid the presence of unwanted moisture, while molecular sieves are used in analytical instruments to maintain low humidity levels in order to obtain accurate results. These desiccants ensure a dry environment and thus helps to preserve sensitive materials in pristine condition. Furthermore, storing these materials in a tight container with silica packs makes them safe from much water and remain useful for their purpose.

Automotive Industry Applications

In the automotive industry, desiccants such as activated alumina and silica gel are used to prevent spare parts from getting damaged due to moisture. Activated alumina is used to prevent parts such as brake pads, filters, and gaskets from getting rust or getting moist during storage or transportation. Silica gel is also used to keep the packages free from moisture, thus guaranteeing that the components are in the right state when required.

Silica gel and bentonite clay are used to preserve the quality of automotive interior trims. Silica gel packets are kept in vehicles to absorb moisture that may cause mold formation and bad smells. Bentonite clay is also used in the packaging of upholstery materials to avoid damaging effects of moisture during storage and transportation, to retain the looks and quality of seats and interior fabrics.

Military and Aerospace Uses

Desiccants such as molecular sieves and activated alumina are widely used in military and aerospace industries to prevent moisture damage to equipment and materials. The other application of molecular sieves is in the storage and transportation of delicate electronic parts and weapons systems where low humidity is required. Activated alumina is used in aerospace engineering to prevent moisture from affecting sensitive systems and parts, which are expected to work optimally under harsh conditions.

Unique Applications Only Achievable by Specific Desiccants

High Selective Adsorption: Air Separation

5A type of molecular sieves is widely used in air separation processes because of its selectivity and accurate adsorption characteristics. These desiccants can selectively adsorb nitrogen molecules from air and leave oxygen behind in the process. This selectivity makes molecular sieves to be useful in industries like petrochemicals and natural gas processing since the purity of the separated gases is very important in the operations of the industries. For example, in oxygen production, molecular sieves help to achieve high purity of oxygen, which is important in medical and industrial uses.

Strong Adsorption Strength: Deep Dehydration

Special types of desiccants like zeolites and activated alumina are used in deep dehydration processes. The ability of zeolites to remove moisture from materials to a very low level even under high humidity conditions makes them ideal for use in pharmaceutical manufacturing where moisture content has to be kept to the lowest level. Activated alumina is also used in the natural gas and petrochemical industries to adsorb water vapor from the gas and maintain the quality of the final product and prevent pipeline corrosion. These desiccants’ high adsorption capacity guarantees that even the smallest amounts of moisture are absorbed, which is crucial for preserving sensitive products and processes.

High Temperature and Corrosion Resistance: Gas Purification

Molecular sieves and activated alumina are especially effective for the purification of gases because of their heat stability and high adsorption capacity. Molecular sieves are employed in the purification of natural gas to remove undesirable sulfur compounds so that the gas can meet the required industry specifications. Activated alumina is used to adsorb impurities and water from synthesis gas (syngas) to ensure that the equipment used in the gas processing industry is not compromised. These desiccants are resistant to harsh conditions and have high adsorption capacity for impurities, thus maintaining the purity and quality of industrial gases.

Conclusion

Desiccants are essential in many industries as they help to prevent moisture from affecting products and their quality and shelf life. From the small packets of silica gel found in shoe boxes to the large molecular sieves used in gas purification, desiccants are essential in removing moisture. By knowing the various types of desiccants and their characteristics, we can better comprehend the uses of these products and the roles they play in protecting our goods and maintaining their efficacy.