Introduction to Adsorbent and Absorbent

In the realm of materials science people may use the terms “adsorbent” and “absorbent” interchangeably; nevertheless, they refer to different phenomena. It is important to make a distinction between adsorption and absorption when choosing appropriate materials and methods in many industries. Adsorption refers to when molecules or ions stick to the surface of a material while absorption means that substances infiltrate into the inside of a material. This paper will discuss in detail adsorbent vs absorbent, their mechanisms and real-life applications.

To comprehend how important adsorption and absorption are consider this statistic: by 2025, global molecular sieve market which is one of the main adsorbents would reach worth USD 5.8 billion at CAGR 5.6% over the period beginning from 2020 up to 2025 (MarketsandMarkets, 2020). Its growth is driven by the increasing need for molecular sieves used in several applications such as gas separation, petrochemical processing and catalysis. Molecular sieves are widely used in oil and gas industry for purification of natural gas as well as removing contaminants like water, sulfur compounds, carbon dioxide etc. As we discuss distinguishing between adsorbents and absorbents, please remember their significant influence on our day-to-day life and industries.

Absent in and Occupied by Common Products

Adsorption-Utilizing Commodities

Different products and procedures rely on adsorption. For instance, activated carbon is one of the most common adsorbents used in water filters, air purifiers, and gas masks. Due to its high surface area and porous structure, it readily adsorbs impurities, odor or contaminants. Another example is silica gel which is commonly found in desiccant packets that come with electronic devices or clothing. Silica gel absorbs moisture from the air to prevent damage to delicate items. Molecular sieve, alumina or zeolites are examples of adsorbents used in chromatography to separate and purify mixtures based on the selective adsorption of different components.

Absorption-Based Products

There are also many absorbent products that we use in our daily lives. Classic examples of absorbent materials include paper towels and sponges that sop up liquid spills. Superabsorbent polymers are used in diapers and feminine hygiene products because they can take in large amounts of liquids without leaking them out again). In medicine absorbent wound dressings are employed for handling exudates while facilitating healing. Industrial absorbents made of polypropylene or cellulose-based materials are employed during oil and chemical spill clean ups such as Sorbents International’s Oil Spill Eater II (OSE II). They draw liquids into their bulk structure effectively containing them after which they can be removed from the environment.

Detailed Comparison: Adsorption vs Absorption

Bulk Phenomenon versus Surface Phenomenon

Where the process occurs represents one of the key distinctions between adsorption and absorption. Adsorption is a surface phenomenon where molecules or ions of a substance being adsorbed (adsorbate) stick to the surface of an adsorbent material. It is brought about by intermolecular forces. The adsorbate forms a thin film on the surface of adsorbent but they do not penetrate into its bulk. Conversely, absorption is the penetration of an absorbate (substance being absorbed) into the absorbent’s bulk structure. The absorbed molecules are dispersed throughout the material occupying spaces between the absorbent molecules.

Heat Exchange and Energy Requirements

Adsorption and absorption processes often entail heat exchange and have different energy requirements. Normally, adsorption is considered an exothermic process, meaning that there is a release in heat as adsorbate molecules stick to the surfaces of an adsorbent because these interactions cause system-wide decreases in energy. Some common examples of adsorption include the use of activated carbon to remove impurities from water or air, and the use of silica gel to adsorb moisture from the air. However, in other cases, absorption can be either an exothermic process or an endothermic process (heat-absorbing), depending on the specific system and how both respond with each other, e.g., the absorber–adsober relationship prevailing within them. This implies that for any given process, the amount of energy required will vary based on factors such as the solubility aspect between the absorbate and absorbent, as well as the intermolecular force intensity.

Dependency on Temperature and Pressure

Temperature and pressure are significant factors in both processes; absorption as well as adsorption. At lower temperatures, more kinetic energy remains with individual particles leading to low probability sticking onto surfaces resulting more favorable conditions for it than at higher ones because at higher temperatures, temperature increases then desorbs greater quantities from this surface due to their increased energies which lead to enhanced sticking probability by increasing them above certain threshold levels. As regards pressure effects too, adsorption goes hand in hand with it whereby higher pressures are associated with greater amounts of adsorption. This is due to the fact that higher pressure leads to an increase in the concentration of adsorbate molecules on the surface of an adsorbent which tends to promote their sticking.

Absorption also undergoes changes as a result of temperature and pressure though this depends on various factors. At times, the solubility of absorbate increases with increasing temperature making absorption more effective at high temperatures. However, other cases indicate higher temperatures decrease absorption because there will be more molecular movement and less attraction between them. In addition to this, pressure can influence absorption particularly in gas-liquid systems since higher pressures increase gas solubility into liquid absorbents.

Mechanisms and Processes

Van der Waals Forces and Chemical Bonds

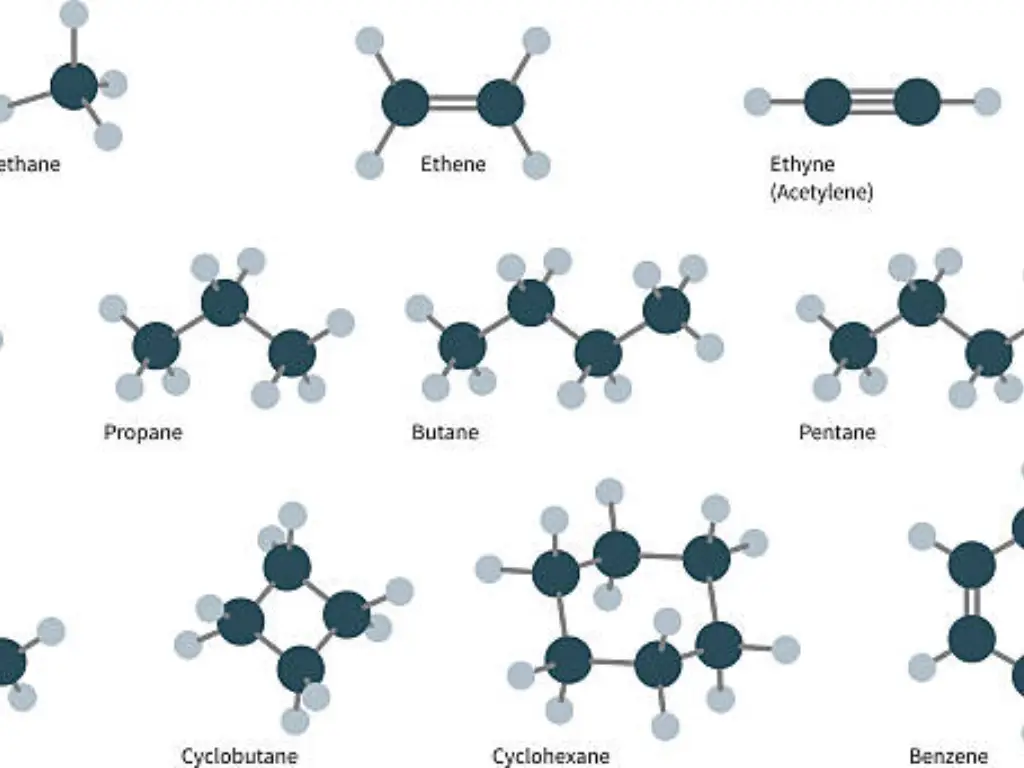

Adsorption can be understood differently considering the nature of the adsorbate as well as the adsorbent. Mainly, physisorption which is a physical adsorption and chemisorption that is chemical adsorption are common types of adsorption. Physisorption binds an adsorbate to an adsorbent’s surface through weak van der Waals forces like dispersion or induction forces between polar molecules for example. These forces tend to be relatively weak making this type of process reversible in nature. Low heat of adsorption, multilayers’ formation on adsorbate/adsorbent boundary characterize physisorption.

In chemisorption, molecules in contact with the surface form chemical bonds with it. These chemical bonds are stronger than those involved in physisorption such as van der Waals forced hence often involve sharing or electron transfer between the absorbate molecule and the absorbent compound. Chemisorption takes place irreversibly and exhibits a high heat of absorption. Monolayer coverage usually occurs when chemisorption takes place on surfaces that possess specific sites where chemical bond formation occurs.

Diffusion, Solubility and Capillary action

Absorbing gets absorbed into materials by permeating their structure by absorbing molecules. The mode of absorption varies depending on several factors among them; they include but not limited to porosity, intermolecular force, absorbents retroflexion etc.The principal means via which molecules get absorbed is diffusion whereby particles migrate from regions having higher concentratiory into areas having lower ones throughout the bulk material under consideration.A concentration gradient will determine how fast diffusion occurs, while temperature influences its outcome.

A second important factor influencing absorption is solubility—how much a substance will dissolve in a given liquid phase.Dependence on temperature and pressure aside, solubility hinges on intermolecular forces that persist between absorbate and absorbent. The more soluble a material is, the greater its absorption will be. In certain instances, capillary action comes in to help absorption; for example adsorbent materials with pores. This takes place when the adhesive forces between liquid absorbates and walls of absorber’s pores become larger than the cohesive forces inside this liquid.As a result, such fluid is pulled by the adsorbate into the absorbing medium making it to enhance absorption.

Real Life Applications of Adsorption

Adsorption in Water Treatment

In water treatment processes, adsorption is an important process for removing contamination, heavy metals and organic pollutants. For instance, activated carbon is commonly used as an adsorbent in water purification systems because of its high surface area and porous structure. It effectively adsorbs a wide variety of impurities including chlorine, pesticides, herbicides and volatile organic compounds (VOCs). The process of adsorption in water treatment can be performed through various means such as fixed bed or powdered form where the activated carbon passes through the water or the activated carbon will be mixed with the water and then separated from it by filtration respectively. Zeolite powder is another example which acts as a type of molecular sieve that is widely employed as an adsorbent in water purifications systems due to its large surface area and its selective adsorption properties. Zeolites are effective at absorbing many different impurities like ammonia, heavy metals, and organic compounds. For instance they may carry out their operations either fixed-bed style or in suspension mode whereby the particles will be added directly into water before being filtered off.

Another case where adsorption occurs in water treatment involves ion-exchange resins. These resins contain functional groups that selectively take up certain ions from the solution while replacing them with other ions. In particular cation exchange resins can eliminate positively charged ions like calcium and magnesium which cause hardness to drinking-water. On the contrary this can also be done by anion exchange resins for example nitrates and sulfates which are negatively charged. Ion-exchange resins are reversibly adsorbed whereby regeneration is possible by washing them using concentrated solutions containing replacement ions.

Adsorption in Air Purification

Air purification is one of the major applications of adsorption to remove unwanted substances, smells, and organic solvents (VOCs) from outdoor and indoor air. It has been common practice for air filtration systems to use molecular sieves like zeolites as adsorbents. The crystalline structure of zeolite possesses well defined pores and thus can selectively adsorb specific gases or pollutants depending on their size or shape at a molecular level. For instance, carbon dioxide, nitrogen oxides and sulphur dioxide are some of the gases that have been removed efficiently by zeolites from industrial exhaust fumes which have helped in lowering global warming potential as well as enhancing air quality.

Besides zeolites, activated charcoal is another famous adsorbent used during air cleaning process. It is able to remove many forms of organic substances such as VOCs, smells and poisonous gases. In manufacturing sectors, like the chemical production industry where a lot of gases are emitted into the surrounding environment, activated carbon filters help in controlling emissions. Activated carbon with its high surface area and its nature being porous tends to trap different types of airborne contaminants thereby leaving cleaner atmosphere that will definitely guarantee safety to both workers’ health and the whole ecosystem.

Adsorption in Industrial Processes

Adsorption is a process that is extensively employed in industrial processes with molecular sieves and activated alumina being some of the most common adsorbents. When it comes to purifying and separating hydrocarbons, molecular sieves are commonly used in the petroleum and petrochemical industry. They do this through selectively absorbing certain hydrocarbon molecules depending on their size or shape thus enhancing effective separation of the desired products from mixtures. For example, zeolites are used in removing impurities and improving gasoline octane during manufacturing.

Silica jelly is a moisture-adsorbing substance that has excellent properties for industrial use as a desiccant. It is often put into packs of things like electronics, drugs and foods, which would otherwise get spoilt by dampness. Silica jelly always absorbs moisture from surrounding air hence maintaining dryness within its package. In addition to that, they also help in separation and purification of various compounds in chemical industries since it is utilized as a stationary phase in chromatography. The affinity for an adsorbent enables efficient separation on silica gel due to selective adsorption on different substances.

Another critical adsorbent that finds applications in several industrial sectors is activated alumina. In natural gas industries, activated alumina can be used to eliminate water or sulfur compounds from natural gas streams; these compounds may have severe effects on people who come into contact with them as well as cause damage to equipment such as pipelines which transport them. Activated alumina’s absorption procedure ensures that the natural gas fits within tight specifications necessary for transmission via pipelines or normal consumption purposes. Activated alumina can also offer support materials when making catalysts where active metal components will be supported by this type of media structure. The high surface area available on activated alumina due to its porous nature provides an ideal medium upon which catalytic metals can spread out thereby increasing their activity and selectivity with respect to chemical reactions happening thereon.

Real-World Applications of Absorption

Absorption in Refrigeration Systems

In refrigeration systems, absorption is very important, specifically in the case of absorption refrigerators and chillers, which have significant industrial applications. A typical refrigerant for these systems would be water or ammonia that will be absorbed by an absorbent like lithium bromide or water, respectively. The absorption process, which can be classified as either physical absorption or chemical absorption, happens in the absorber, which is where refrigerant vapor is absorbed by the absorbent solution, thus releasing heat. From here, the absorbed refrigerant gets pumped to a generator where it gets heated, thereby causing the refrigerant to desorb from the absorbent and then vaporize. Once more, the refrigerant vapor goes through the entire cycle of cooling while at the same time, in order to repeat this process, namely, returning an absorbent back into an absorber.

Compared with traditional vapour compression systems, there are several advantages of absorption refrigeration systems, including power sources and environmental issues. They can run on low-grade heat, such as waste energy from industrial processes or solar thermal energy, making them more eco-friendly and efficient as well. Again, absorption systems use non-ozone-depleting refrigerants and have fewer moving parts, which result in lower maintenance than with these types of plants; although they are larger and more expensive than vapour compression systems, hence not widely used.

Absorption in Medical Fields: Drug Administration and Delivery

Absorption in the medical field is a very critical concept and more so in drug administration and delivery. When a drug is taken orally, it has to be absorbed from the gastrointestinal tract into the bloodstream where it can act on its target organ. Factors that affect drug absorption include solubility of the drug, pH of the gastrointestinal environment, presence of food in the stomach among others. Some drugs are designed to get absorbed quickly to produce an immediate effect while others have been formulated for slow absorption hence creating sustained release of their active substance over time.

In topical drug delivery, absorption also plays a role when medications are applied on the skin or mucous membranes. In this case, for example, some drugs must be absorbed by passing through either skin or mucous membrane to reach underlying tissues where they carry out their intended purpose. For example transdermal patches are made to deliver medications at constant rate via skin, which allow non-invasive and convenient route of administration. Drug absorption through the skin depends on such factors as lipophilicity of drugs, molecular size and status of the keratinized barrier.

Absorption in Daily Life: Spill Control

For example, in our day to day lives we come across and hence use absorbent materials for spill control and cleaning. Paper towels, sponges and mops are all household items that soak up liquid spills through their ability of absorbing them. Hence, these substances are designed with high absorption capacities that enable them to get rid of liquids on surfaces quickly and efficiently. This is why industries employ the use of absorbent materials such as polypropylene pads or booms for oil and chemical spills clean up. These materials naturally repel water but can soak in oils as well as other hydrocarbons because they are hydrophobic making it good for removing specific species from aqueous systems.

Also, absorbent products like diapers feminine hygiene pads and adult incontinence products utilize superabsorbent polymers into which a large amount of liquid may be absorbed by weight. In these materials when fluid comes into contact with the porous structure of the polymer capillarity attraction together with hydrogen bonding takes place which makes the liquid stick to it. Furthermore, personal hygiene has adopted superabsorbents revolutionizing how personal hygiene products perform such as diapers for effective absorption against odors leading to great comfortability for users.

| Feature | Adsorption | Absorption |

| Process Type | Surface Phenomenon | Bulk Phenomenon |

| Location of Adsorbate | Adsorbate sticks to the surface of adsorbent | Absorbate penetrates the bulk of the absorbent |

| Forces Involved | Van der Waals forces, Chemical bonds | Diffusion, Solubility, Capillary action |

| Heat Exchange | Usually Exothermic | Can be Exothermic or Endothermic |

| Effect of Temperature | Generally, lower temperature favors adsorption | Varies depending on the system |

| Effect of Pressure | Higher pressure increases adsorption | Higher pressure increases absorption (gases) |

| Examples of Materials | Molecular Sieve, Activated Carbon, Zeolites, Silica Gel, Activated alumina | Paper Towels, Sponges, Superabsorbent Polymers |

Jalon: Your Trusted Partner for High-Performance Adsorbent Solutions

Jalon has been recognized as an adored name in the adsorbent market by persistently supplying its worldwide clients with high quality products including molecular sieves, zeolite powders and activated alumina. By comprehending the unique problems faced by different sectors like oil refinery, petrochemicals, natural gases, coal chemicals or environmental field Jalon has become a reliable partner for tailored solutions.

By investing in new technology, stimulating innovation among product development team while maintaining a keen eye on product quality; Jalon has come out as a leader in manufacturing of adsorbents. Entering into partnership with Jalon opens up to you an inclusive variety of high performing adsorbents, wide knowledge of industry and an experienced team that will help you optimize your processes further. With great competition in price and continuous success on customers’ side Jalon is the best option for companies looking forward to finding long-term partners who can be trusted in adsorbent industry.

Conclusion

In conclusion, it is important to realize the distinction between adsorbent and absorbent materials for their effective utilization in various applications. For different purposes, adsorption, which is a surface phenomenon and absorption that occurs at bulk level, differ in their mechanisms and characteristics.

The need for efficient and sustainable solutions will see the development and optimization of adsorbents as well as absorbents remain a key area of focus for research as well as innovation. We can thus develop new materials and technologies that meet the changing needs of different sectors while promoting cleaner, healthier and more sustainable futures by deepening our understanding on such phenomena alongside their underpinning mechanisms.