Luoyang Jalon Micro-Nano New Materials Co., Ltd., a leading supplier of advanced molecular sieve technology, is excited to announce its participation in the 2024 Oil & Gas Asia (OGA) exhibition, taking place from September 25 to 27 at the Kuala Lumpur Convention Centre in Malaysia. OGA is recognized as one of the most significant events in Southeast Asia for the oil, gas, and petrochemical industries, attracting top-tier professionals and companies from around the world.

Company name: Luoyang Jalon Micro-Nano New Materials Co., Ltd

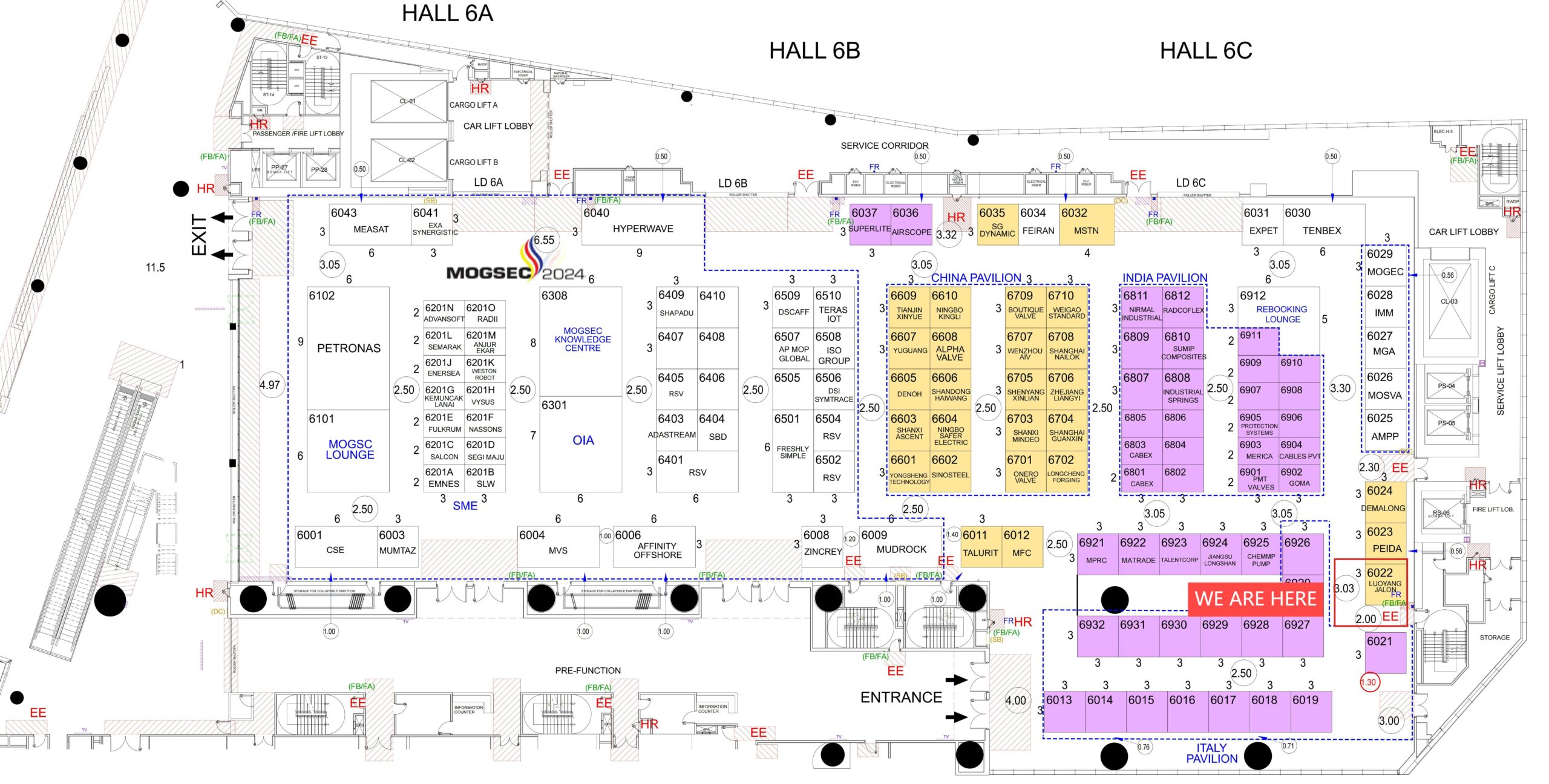

Booth No. : Hall 6 – 6022

Contact Person: Naomi Wu

Tel/Whatsapp/Wechat: +86 15896542404

At this year’s exhibition, Jalon will showcase its latest molecular sieve products, specifically engineered to address the complex challenges faced by the oil and gas industry. Molecular sieves, known for their exceptional adsorption capabilities and selectivity, play a critical role in various stages of oil and gas processing.

Key Applications of Molecular Sieves in the Oil & Gas Industry:

“We are thrilled to participate in OGA 2024, a premier platform for the oil and gas industry. Our advanced molecular sieve solutions are designed to meet the evolving needs of the sector, enhancing process efficiency, reducing operational costs, and supporting the industry’s move towards more sustainable practices,” said Steven Zhao, Director of the International Business Department.

Visitors to the Jalon booth at OGA 2024 will have the opportunity to learn more about how our molecular sieve technology can address specific challenges within their operations, contributing to safer, more efficient, and environmentally friendly practices in the oil and gas industry. Join us at Hall 6 – 6022 and discover how our molecular sieves can power the future of energy.