Introduction to Dehumidifiers

Having too much humidity in your home can lead to lots of issues such as instances of excessive dampness and mold, stale smells, deterioration of the structure of the house, and health complications among other issues. Dehumidifiers were created for that purpose. These useful devices are designed to get rid of excessive humid air in the room for a more pleasing and healthier living space. However, in this sea of types of dehumidifiers available, how do you go about choosing the most effective one for your needs? Against this backdrop, we shall discuss two of the common types of dehumidifiers used – desiccant and compressor dehumidifiers and outline the main features that make them different.

Notably, any indoor space including a home, an office, or any other enclosed area suffers from elevated humidity levels, and this picture is relatively the same when it comes to interpreting all the dehumidifiers. Through the understanding of the merits and demerits that come with each kind of dehumidifier, one is able to clearly understand which type of that dehumidifier best answers their specific requirements.

Types of Dehumidifiers

There are many kinds of dehumidifiers to choose from in order to eliminate excessive humidity in residential or working systems. The most common types include refrigerant (or compressor) dehumidifiers, desiccant dehumidifiers, and thermo-electric dehumidifiers. Among all different types of dehumidifiers, the refrigerants are the most preferred & in fact they are fast & very effective in getting too much humidity from the air. This type of appliance is primarily for use in warmer climates where there is a lot of condensation in large spaces.

In contrast, desiccant dehumidifiers work on some moisture sequestration agent like silica gel or molecular sieve in order to get humidity from the air. Thus, they work well at lower surrounding temperatures; in particular, they can be effective at lower humidity levels than the refrigerant types. On the other hand, thermo-electric dehumidifiers are not widely used, but they need Peltier’s effect for their metal plate cooling system to draw moisture vapour from the air. These are pretty much smaller and quieter when operating compared to the rest of the dehumidifiers but are limited in the water removal capacity.

This effort will be concentrated on two of the very popular forms of dehumidifiers, desiccant dehumidifiers and compressor (refrigerant-based) dehumidifiers. With this information, we will examine the principal mechanism of their operation, advantages and disadvantages, and help you to decide which type of dehumidifier is perfect for your needs.

Understanding Desiccant Dehumidifiers

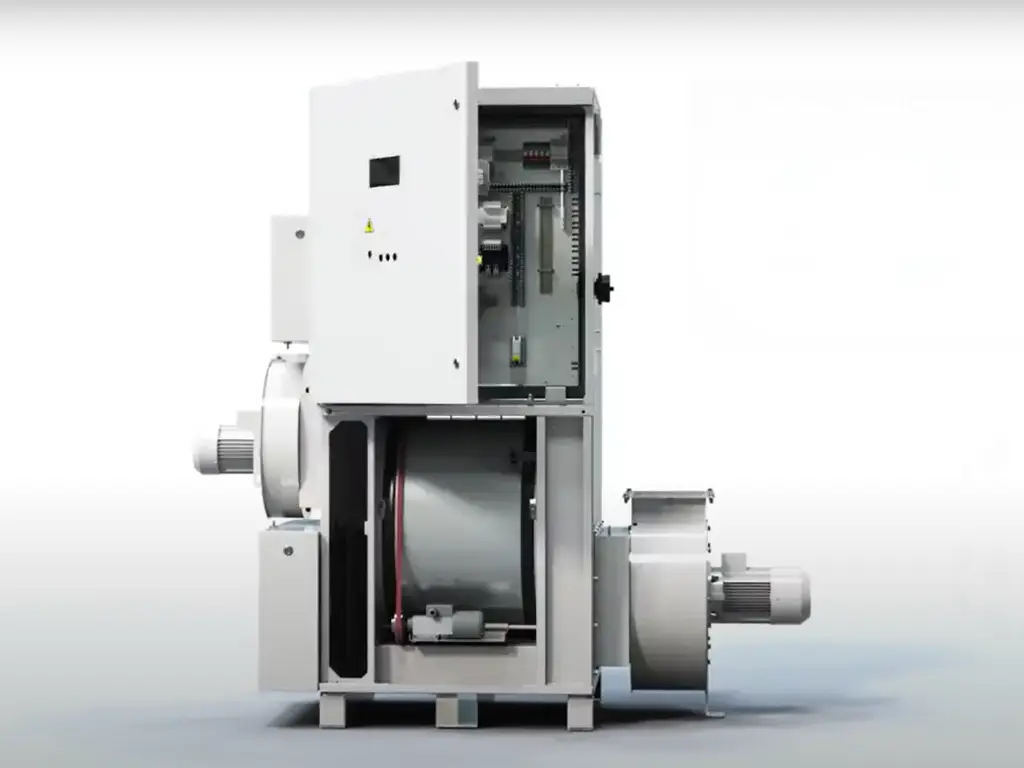

How Desiccant Dehumidifiers Operate

In case of desiccant dehumidifiers, moist air is drawn into the fan and made to pass through a rotor which contains desiccant material. For example, molecular sieve or silica gel acts as a moisture-absorbent. So, as the air passes through the rotor, the desiccant material absorbs its moisture, and on the other side dry fog-free and conditioned air comes outside the rotary if further blown into the room. The saturated desiccant is then put through a heating element to elicit the water content that can be stored in a tank for later use or it can be emptied using a hose.

The Role of Molecular Sieves in Desiccant Dehumidifiers

In desiccant dehumidifiers, particularly those in households, molecular sieves have greatly improved the performance of the devices. These are highly porous materials, having a regular pore structure which makes it possible for these materials to effectively get moisture and allow air to pass through. Whereas, other types of desiccants like silica gel, which have been in use for long periods now, tend to be less effective in dry climates, molecular sieves perform equally well even in low humidities. Due to this unique structure, they can more effectively absorb and hold moisture, which contributes to better performance with regard to dehumidification. Additionally, it is noted that the molecular sieves have good regeneration capacity and therefore can be used over and over again with only minimal efficiency loss. As suppression of moisture is critical in many applications, molecular sieves can be incorporated into a desiccant dehumidifier that works and alleviates issues of bulkiness and power consumption on the device.

Understanding Compressor Dehumidifiers

The Working Mechanism of Compressor Dehumidifiers

Compressor dehumidifiers are similar to air conditioners. For instance, they pull humid air towards themselves and blow it over a cold evaporator coil. The air that changes phase cools, and the condensation flows onto the coil where it ultimately drains to a tank or outlet. The now cool and dry air is reheated and discharged to the room space. This goes on until the targeted humidity level has been achieved.

Benefits of Compressor Dehumidifiers

For this reason, most people prefer to use compressor dehumidifiers since they can remove a lot of moisture, which makes them perfect for big areas or zones where the humidity levels are still too high. Energy wise, they are more efficient than desiccant models because they do not have to keep a heating of the regenerator that generates the desiccant material for the models.

However, compressor dehumidifiers have their own disadvantages. Because such units have moving components for example the compressor and fan, they have to be quite loud. Such dehumidifiers may also work poorly in low temperatures, because, in some instances, the evaporator coil can freeze, and that damages the system. Most compressor dehumidifiers are also more pricey compared to desiccant models.

Performance Comparison

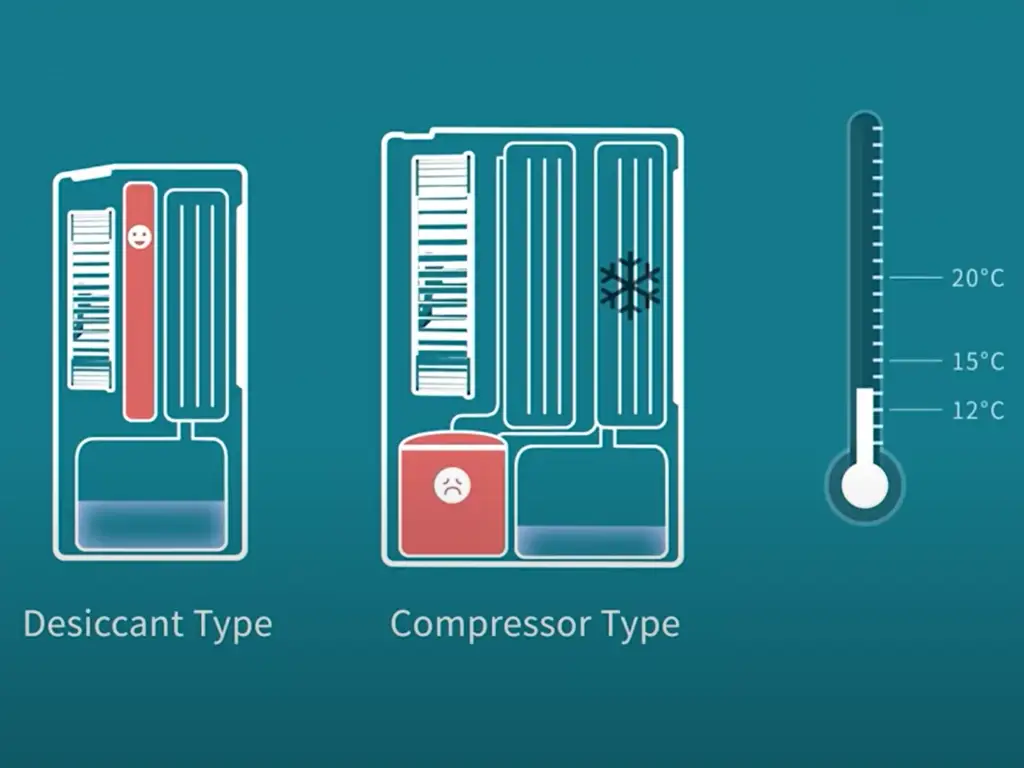

Efficiency in Different Temperature Ranges

One distinguishing feature of desiccant and compressor dehumidifiers is how well each works, within the specified temperature ranges. This is most pronounced in conducive temperatures and humidity where compressor dehumidifiers are mostly used which cut above the 15°C threshold. At the same time, desiccant dehumidifiers are regarded as efficient and can be used effectively at rather low temperatures, some even below 1°C. Such makes them ideal for use in unheated areas like garages and basements.

Moisture Removal Capacity and Speed

When it comes to the rate at which moisture can be removed from space and the total amount of moisture removed, compressor models appear to take the day over desiccants. This is because dehydration of the air in such instances will take place in the far quicker speed with the help of the compressor dehumidifiers. When used in highly humid and or moisture laden areas or where there are moisture problems, these units will perform with great ease. The effectiveness of the desiccant dehumidifiers although evident with the determination of vast humidity levels in space may take long to respond to such targets even when the space is smaller.

Cost and Energy Efficiency

In terms of sticker price and energy consumption, there are advantages and disadvantages to be found in desiccant and compressor dehumidifiers. Desiccant dehumidifiers often come at a lower initial capital quite a bit while operating under cooler climates as these do not consume as much energy. However, they tend to be more energy-consuming in heat generation that is necessary for the reuse of the impressed water in the desiccant.

Compressor dehumidifiers but instead it is likely that even though there is more money spent initially, they are likely to be more energy efficient in hot climates. In addition, a separate heating element is not necessary, which means saving energy consumption. On the contrary their efficiency drop in cooler climates and even though they are quite effective, it is likely that, these will be very inefficient and quite energy consuming due to unfavorable conditions than the desiccant ones.

Noise Level and Regular Maintenance

Another aspect worth measuring before picking a desiccant dehumidifier over a compressor one, especially when considering a whole house dehumidifier, is the noise level and maintenance requirements for the devices. Desiccant dehumidifiers are normally less noisy than compressor models as they do not have a compressor or big fan, allowing for quieter operation. This makes them a better choice and quite suitable for say bedrooms, offices and other quiet places.

Looking at maintenance practices of both dehumidifiers, there are some filters and cleaning that ought to be regularly done, in order to enhance efficiency and effectively remove moisture. However, in the case of desiccant dehumidifiers, servicing of this device may be needed more on a recurring basis as the desiccants tend to collect moisture over time.

Suitability for Different Environments

The use of a desiccant dehumidifier is more convenient in a close place with low to moderate moisture content like bedrooms, home offices, or small apartments. They are also a good choice in cooler surroundings like unheated garages or basements where compressor dehumidifiers might not work properly.

Compressor dehumidifiers, on the other hand, are perfect for larger areas that have high moisture content like living rooms, kitchens, or even a whole house. They are also suited in hot weather conditions like during humid summer months or even in tropical regions where their high moisture extraction properties can aid control of relative humidity & comfort indoors.

| Feature | Desiccant Dehumidifier | Compressor Dehumidifier |

| Ideal Temperature Range | Works well at lower temperatures, even below 1°C | Most effective at temperatures above 15°C |

| Moisture Removal Capacity | Generally lower than compressor dehumidifiers | Higher moisture removal capacity, especially in larger spaces |

| Energy Efficiency | More energy-efficient in cooler environments | More energy-efficient in warmer environments |

| Noise Level | Relatively quiet operation due to absence of compressor | Tends to be louder due to compressor and fan noise |

| Initial Cost | Generally lower initial cost | Higher initial cost compared to desiccant models |

| Maintenance Frequency | May require more frequent maintenance (desiccant replacement) | Generally requires less frequent maintenance (filter cleaning) |

| Suitable Environment | Ideal for low to moderate humidity levels and cool temperatures | Well-suited for high humidity levels and warm temperatures |

Partner with Jalon for Your Molecular Sieve Needs

When it comes to the high-quality molecular sieves, Jalon is the first and foremost option, as there are various products for various dehumidification needs. Being an industrial scale manufacturer with over 20 years of experience, Jalon caters to the equipment manufacturers, professionals working in industries needing efficient humidity control, and high end consumers looking for the best dehumidification systems. Working with Jalon clients gain technical support, product modification, and regular high quality products. The best molecular sieves that Jalon offer, will most definitely let you overcome all problems in designing your dehumidifiers or improving the present system you have.

Conclusion

To sum up, it can be said that there are no perfect answers when one has to choose between a desiccant or compressor dehumidifier. Your particular case will determine the most appropriate option based on your dehumidification space characteristics, budget and energy efficiency considerations. A summary of the differences between desiccant and compressor dehumidifiers with regards to their target audience would help immensely in helping you choose the right dehumidifier for your home or any other premises.