PSA Oxygen Generators

- Home

- Application

- PSA Oxygen Generators Draft

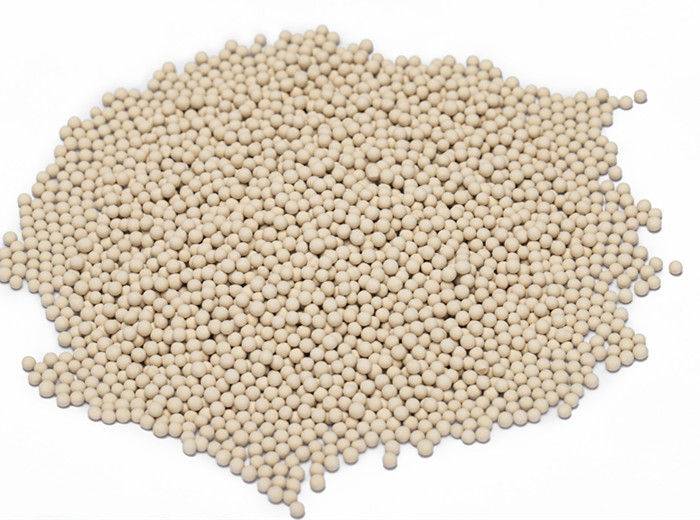

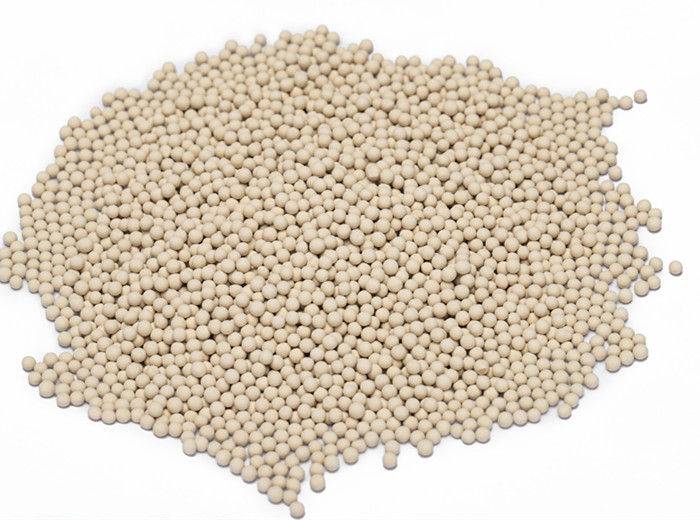

Optimized Molecular Sieve Solutions For PSA Oxygen Generators

Related Products To Complete Your Project

How Jalon Molecular Sieve Revolutionizes PSA Oxygen Generator

Consistent 93%±3% Oxygen Output

Crafted with premium zeolite and precise pore control, our molecular sieves optimize nitrogen removal in PSA oxygen generators, ensuring a stable 93%±3% oxygen purity for medical and industrial use.

Exceptional Oxygen Production

Our molecular sieves are designed for high nitrogen capacity and rapid adsorption cycle <12s, ensuring faster PSA cycles and a stable oxygen flow, providing a higher oxygen yield per minute for broader applications.

More Economical Oxygen Supply

By efficiently removing nitrogen with minimal energy input, our molecular sieves lower the energy consumed per liter of oxygen in PSA oxygen generators, translating to significant savings on your electricity expenses.

Wide Oxygen Generator Compatibility

The zeolite molecular sieve for oxygen concentrator from Jalon is engineered to be highly compatible with a multitude of existing oxygen concentrator models, making system upgrades simple.

Extended Service Lifespan

The robust composition of our zeolite oxygen sieves offers excellent abrasion and chemical degradation resistance, leading to a prolonged lifespan and fewer replacements for the PSA oxygen concentrator.

Oxygen Ready in Moments

For oxygen concentrators needing a quick startup, our oxygen concentrator molecular sieve ensures optimal adsorption rapidly, providing a consistent flow of high-quality oxygen without interruptions.

Safe Oxygen Source

Our molecular sieve for oxygen concentrator is made from inert and non-toxic synthetic zeolite, ensuring it will not contaminate the oxygen supply or pose any harm to health or the environment.

Build Compact Devices

The combination of an ultra-light material and high packing density in our oxygen concentrator molecular sieve empowers manufacturers to produce more compact and easily portable oxygen concentrators.

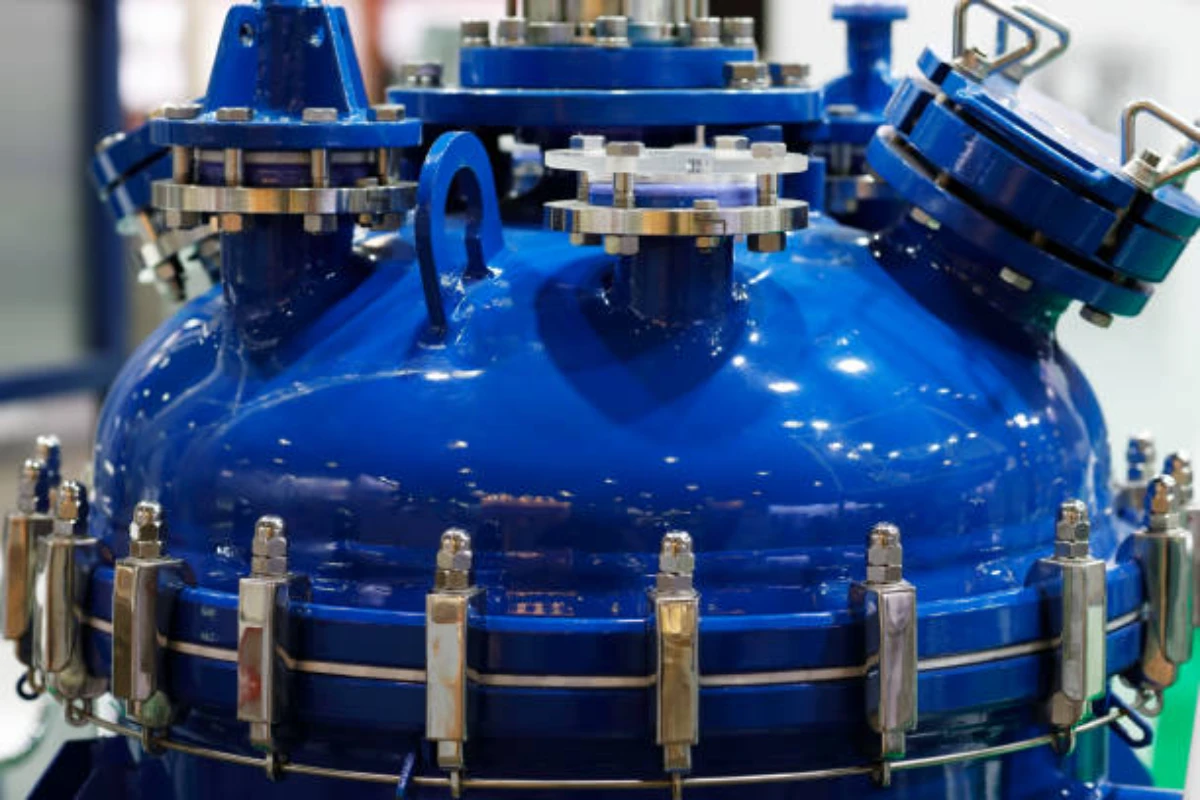

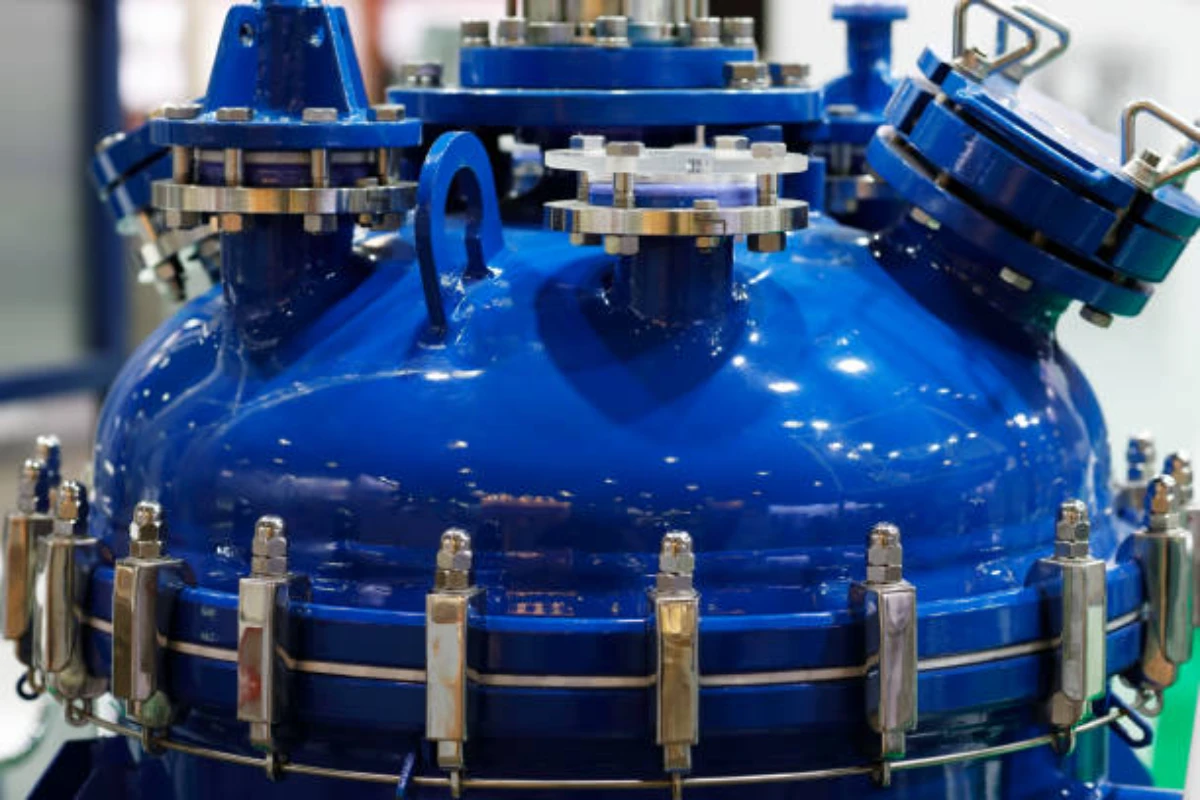

Engineering Success for Diverse PSA Oxygen Generator Applications

● Contributes to the stable and reliable operation of ozone generation systems.

● Contributes to the longevity and stable performance of large oxygen concentrators for medical use.

● Supports the design of energy-efficient PSA medical oxygen generator for high-volume oxygen production.

● Offers a durable and reliable component for a robust industrial oxygen generator.

● Supports the production of cost-efficient on-site PSA oxygen solutions.

● Offers a durable component for PSA oxygen concentrators operating in demanding environments.

● Contributes to the stable and reliable operation of oxygen generators used in glass manufacturing.

● Contributes to the long lifespan and stable operation of the PSA molecular sieve oxygen generation system used in aquaculture.

● Enables reliable oxygen supply of large-scale PSA oxygen concentrator in pulp and paper mills.

● Ensuring the reliability and safety of oxygen supply for chemical processes.

● Enables the design of portable oxygen concentrators for oxygen supply in remote mining locations.

● Offers high packing density, enabling the creation of compact oxygen concentrator designs.

● Ensures reliable oxygen delivery for personal medical use.

● Contributes to the stable and reliable operation of ozone generation systems.

● Contributes to the longevity and stable performance of large oxygen concentrators for medical use.

● Supports the design of energy-efficient PSA medical oxygen generator for high-volume oxygen production.

● Offers a durable and reliable component for a robust industrial oxygen generator.

● Supports the production of cost-efficient on-site PSA oxygen solutions.

● Offers a durable component for PSA oxygen concentrators operating in demanding environments.

● Contributes to the stable and reliable operation of oxygen generators used in glass manufacturing.

● Contributes to the long lifespan and stable operation of the PSA molecular sieve oxygen generation system used in aquaculture.

● Enables reliable oxygen supply of large-scale PSA oxygen concentrator in pulp and paper mills.

● Ensuring the reliability and safety of oxygen supply for chemical processes.

● Enables the design of portable oxygen concentrators for oxygen supply in remote mining locations.

● Offers high packing density, enabling the creation of compact oxygen concentrator designs.

● Ensures reliable oxygen delivery for personal medical use.

● Contributes to the stable and reliable operation of ozone generation systems.

Medical Oxygen

Industrial Combustion Enhancement

Wastewater Treatment

Glass Manufacturing

Aquaculture

Pulp and Paper Industry

Chemical Industry

Mining

Portable Medical Oxygen Concentrators

Ozone Generators

Jalon: Trusted Source for High-Quality Oxygen Concentrator Molecular Sieve

Continuous R&D for Superior Molecular Sieve Oxygen Concentrator Solutions

- Over 78 experienced scientists and engineers dedicated to R&D.

- RMB 40 million invested in advanced research facilities.

- Achieved over 112 patents in technological innovation.

- Strategic collaborations with 6 provincial and 5 joint laboratories.

- Fully equipped pilot plant for advanced technology testing and validation.

- Supported by an academician workstation for groundbreaking research initiatives.

Expert Custom Molecular Sieve Solutions

- Experienced technical team provides complimentary consultation and conducts a thorough analysis of your PSA oxygen generator project requirements and budget.

- Leveraging extensive product knowledge, a rapid recommendation of the optimal zeolite molecular sieve solution tailored to your specific needs and budget is provided.

- Complimentary samples are offered for your testing, and we can also test your samples to confirm our capability for reliable bulk production, regardless of order volume.

Ensuring Peak Performance Through Quality Assurance

- Premium raw materials are ensured through strict supplier selection and in-house zeolite powder production with rigorous testing.

- Precise and stable production is achieved with a DCS fully automated system and a skilled, continuously trained workforce.

- Every batch undergoes strict quality testing using international standards, with customizable options and comprehensive documentation provided.

- Product quality is fully traceable with long-term sample retention, providing customers with added confidence and assurance.

Secure Your Supply with Asia's Largest Manufacturer

- Jalon boasts a massive 47,000 tons annual capacity from its extensive 200,000 sqm production base.

- Factories in mainland China and Thailand ensure reliable supply and consistent quality for global markets.

- Strategically located near ports and airports for efficient delivery and a responsive global supply network.

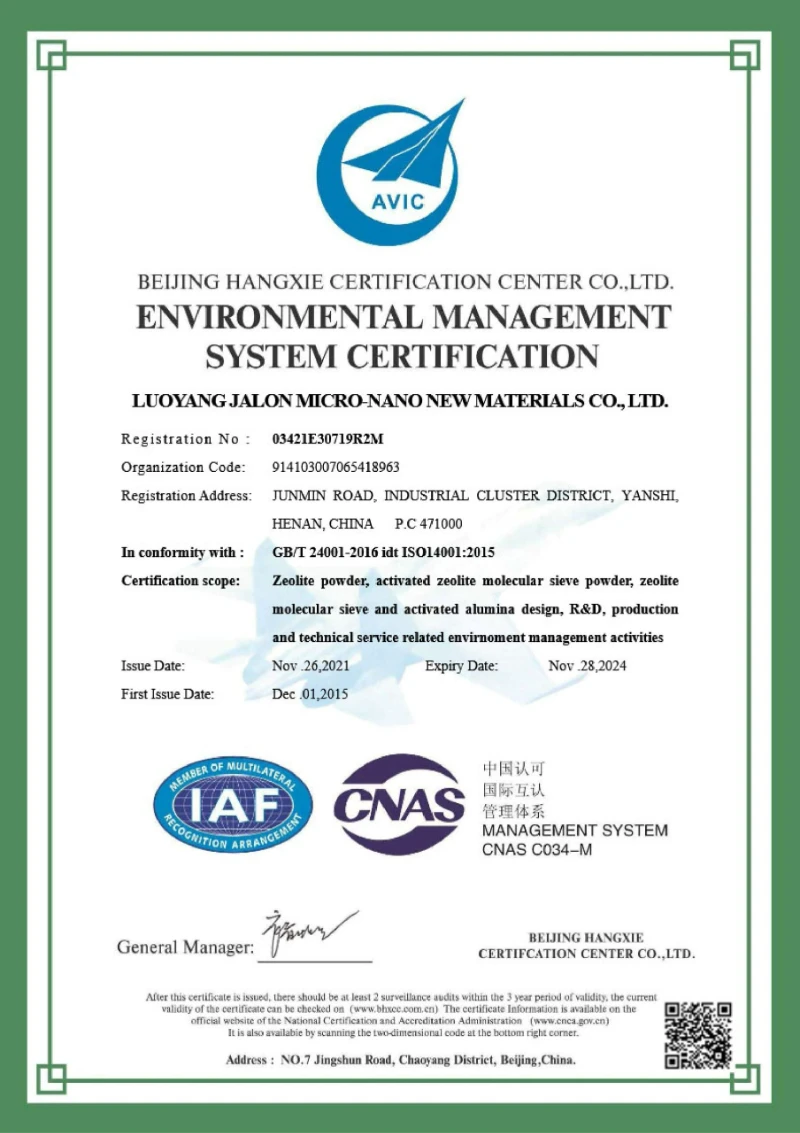

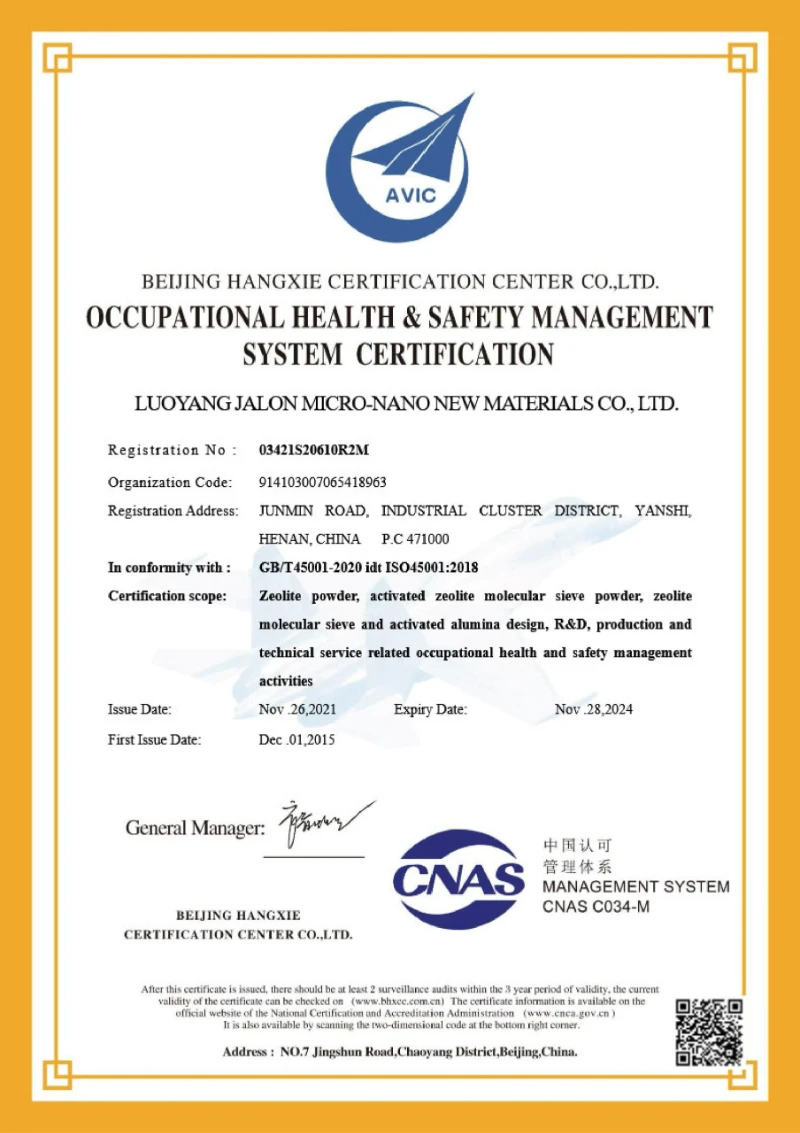

Our Certifications: Your Assurance of Quality

At the core of our work is a commitment to empowering PSA oxygen generators with reliable and high-performing molecular sieves. Our certifications are not just accolades; they are promises of excellence you can trust.

ISO50001 Energy Management System Certification

IATF16949 2016 Certificate

European Patent Certificate

US Invention Patent Certificate

ISO14001: 2015

ISO45001: 2018

ISO9001: 2015

ISO50001 Energy Management System Certification

IATF16949 2016 Certificate

European Patent Certificate

US Invention Patent Certificate

ISO14001: 2015

ISO45001: 2018

ISO9001: 2015