We value your privacy

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

No cookies to display.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

No cookies to display.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

No cookies to display.

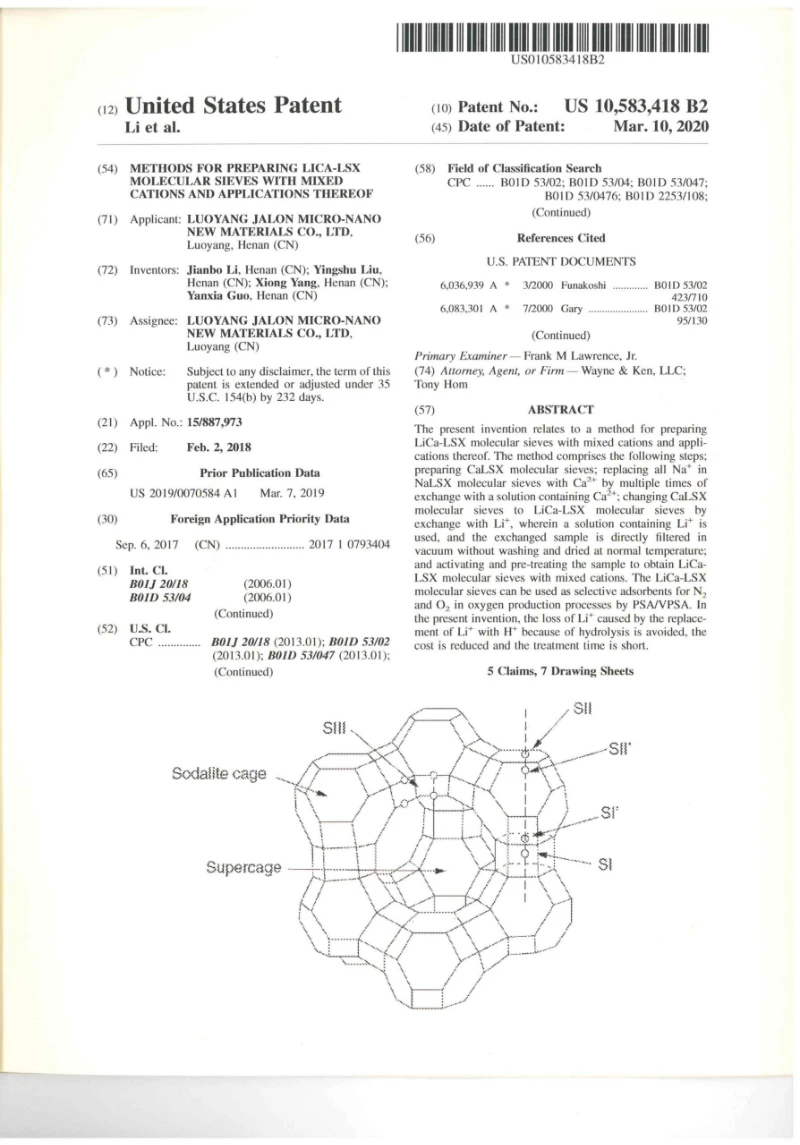

– Learn how Jalon lithium-based X-type zeolite sieve outlast A types and 13X –

At the core of our work is a commitment to empowering VPSA industrial oxygen generators with reliable and high-performing molecular sieves. Our certifications are not just accolades; they are promises of excellence you can trust.

Installed in 2012, the VPSA-2 equipment at Glencore's Southeast Asia Subsidiary was designed for a capacity of 4000 Nm³/h with an oxygen purity of 89%-91%. However, since October 2018, its oxygen purity has gradually declined to 37.7%. The decline in oxygen purity was attributed to the deterioration of the adsorbent's performance, as determined by analysis.

To address this, approximately 84.278 tons of adsorbent were replaced in the VPSA-2 system. All required materials, including activated alumina, molecular sieves, ceramic balls, mesh screens and subsequent loading technical services for this project are provided by Luoyang Jalon Micro-Nano New Materials Co., Ltd.

Focusing on innovation and quality, we strive to make industrial oxygen generation more efficient, stable, and eco-friendly, building trusted partnerships with our customers. Our case studies show that clients are satisfied with the results time and time again.

The primary difference between PSA and VPSA lies in how they regenerate the adsorbent materials during the desorption process. PSA systems release pressure to regenerate the adsorbents, while VPSA systems use a vacuum, which is more energy-efficient and enhances system performance.

PSA is typically used for smaller-scale applications with moderate oxygen demand, offering a compact design suitable for moderate gas flows. In comparison, VPSA is better suited for larger-scale, continuous applications requiring high oxygen demand, as it utilizes larger systems optimized for higher gas flows.

From an energy and cost perspective, PSA systems tend to consume more energy and have higher operating costs for large-scale applications. In contrast, VPSA systems are more energy-efficient due to vacuum regeneration, resulting in lower operating costs, making them ideal for industrial-scale use.