Introduction to Product Preservation

The preservation of products is an important feature in many fields, allowing goods to be kept in a desirable state from the moment they are produced to when they are consumed. Be it food products, medication, or electronic parts, everyone wants the products to be maintained at optimum conditions, and any business cannot afford dissatisfaction from clients. The factors that come into play especiallytwo factors are moisture and oxygen.

Too much moisture and oxygen can brought by many problems such as development of molds, oxidation process and wear-and-tear of the substances. Thus many industries implement preservation methods such as putting desiccants as well as using oxygen absorbers. The deferences and uses of desiccants and oxygen absorbers in various fields will be the focus of this article.

The Role of Moisture and Oxygen Control

Moisture and oxygen are the two factors that can most influence the quality cascading of products and its shelf duration. Extra moisture content can help in the flourishing of microorganisms, for instance, mold and bacteria, leading to deterioration of foodstuffs and other materials. On the contrary, oxygen can also contribute to deterioration of the foodstuff by causing oxidative reactions which adversely affect nutrients, flavors and colors of the food as well as drug and electronic components.

To maintain the moisture and oxygen concentration, various preservation forces are utilized by the industries. These include modified atmosphere packaging, vacuum packing as well as use of desiccants and oxygen scavengers. Desiccants are materials that can draw moisture from the environment around them while oxygen scavengers deplete oxygen from tight packages of food substances. By adopting these strategies both in unison or individually, the companies can enhance the quality of their products and prolong the period of their usability.

Types of Desiccants and Their Applications

Desiccants are substances that take up moisture from the air, thereby keeping the internal packing or the storage environment dry. There are many varieties of such desiccants and each is used for a specific application. Silica gel and absorber gel are two of the most common desiccants.

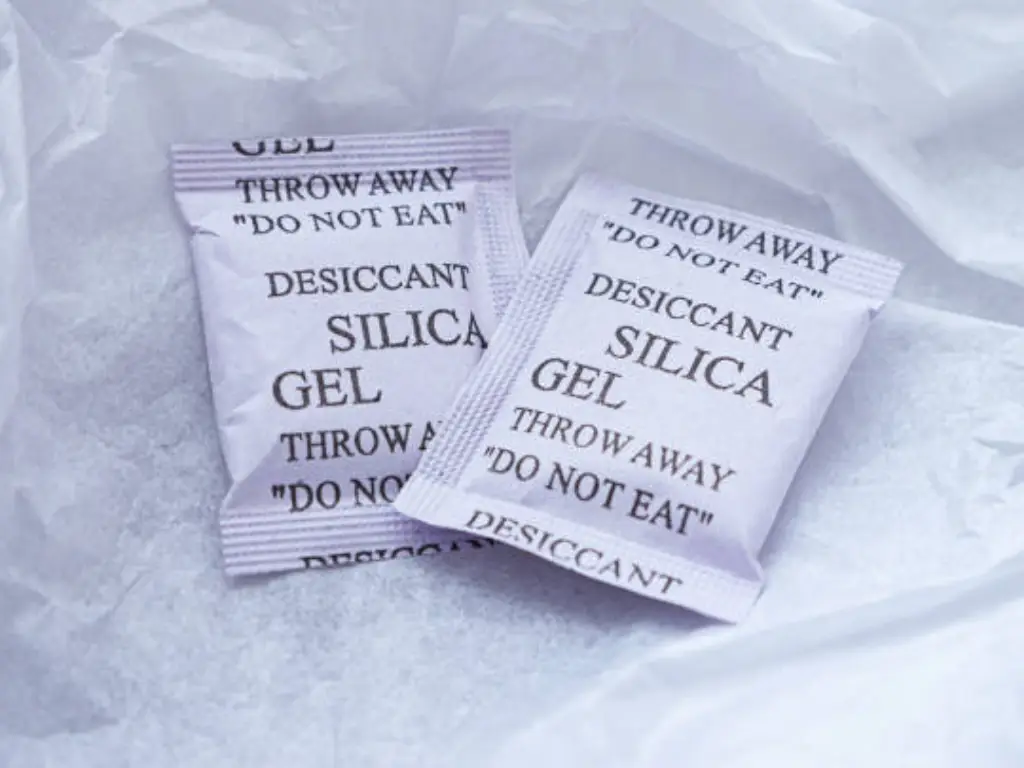

Silica Gel

Silica gel is a well-known type of desiccant with many applications in several industries. This is due to its porous structures which are silica. It is included in small envelopes or sachets which are then added to the packaging of the products in order to avoid contact with the items with moisture. One of the benefits of silica gel is its ability to be replenished by heating, which drives off the moisture it has absorbed.

Apart from moisture control in the manufacturing process, silica gel is utilized in the packaging of low moisture content foods like crackers, chips and spices. Also, it is utilized within the pharmaceutical industry to preserve the medication away from the humidity, and within the electronics industries to minimize humidity induced short circuited and rust.

Molecular Sieves

Molecular sieves are another type of desiccant that are highly effective in absorbing moisture in various industries. They are made from synthetic zeolite, a porous form of silicon dioxide with a uniform pore size. This uniform pore size allows molecular sieves to selectively absorb molecules of a specific size, making them more efficient than silica gel in different applications.

Molecular sieves are crucial in the pharmaceutical and electronic industries as they help to provide comprehensive protection for moisture-sensitive products. In the pharmaceutical industry, they protect active ingredients from moisture damage, thereby improving the longevity of the drugs through a controlled chemical reaction. In the field of electronics, molecular sieves protect components from moisture problems like corrosion, short circuit, etc., which could affect the functioning of the components. Manufacturers incorporate molecular sieves in the packaging to maintain a dry environment, which improves the shelf life of different products like drugs and electronics.

Understanding Oxygen Absorbers

Oxygen absorber packets are sachets wherein the materials contained are the ones that chemically combine with the oxygen present in the sachet and remove it from there. The most basic oxygen absorber consists of a storage container with iron fillings, which get oxidized to iron oxide when brought in direct contact with oxygen. This lowers the oxygen quantity within a wrapper or container because less oxygen is present in the atmosphere of such an enclosed container and helps to keep the ingredients stable and fresh for a long time.

The main providers of oxygen absorbers are the food and cosmetics industries which seek to treat and increase the shelf life of air-sensitive products such as processed meat, cheese, and baked products. As such, oxygen absorber packets play a key role in eliminating oxygen from the food packaging and inhibiting the proliferation of aerobic spoilage microorganisms, as well as preventing oxidative deterioration of fats and oils that cause rancidity. Additionally, moisture absorbers are employed to tackle excess moisture, further protecting the quality of the goods.

Silica Gel vs Oxygen Absorber: A Comparative Analysis

It is equally important to know their differentiating characteristics and the needs of your products when faced with a choice of using either silica gel or oxygen absorbers for the preservation of your products. A desiccant, silica gel is an absorber of moisture in a barring location in order to keep the package dry. In contrast, oxygen absorbers are used only to eradicate oxygen from rigid seals by ensuring no oxygen stasis in the enclosed bottle to protect the quality and freshness of the goods.

Though both these resources are equally valuable for packaging protection and shelf life improvement, the scope of application for these materials is different. For some instances, the products may be exposed to moisture as well as oxygen and therefore both silica gel and oxygen absorbers need to be used in those cases. However, one must understand that these two products have different roles to play in preservation, and misuse cannot be tolerated.

One such distinct point of difference in the studies for silica gel and oxygen emitters is the mode of the primary use. Silica gel is classified as a moisture sorbing material and so cannot eliminate the gaseous materials from any sustained environment. In the same way, oxygen emanators do not have a moisture absorbing capability hence ill-suited to keep the products dry from moisture damage.

Molecular Sieves vs Oxygen Absorber: Key Differences

Molecular sieves and oxygen absorbers are both used for product preservation but they work on different factors that may affect the quality and shelf life of products. Molecular sieves are meant to selectively adsorb molecules of a certain size and are therefore very useful in managing moisture content in packaging. This property makes them particularly suitable for use in industries where moisture control is important such as in the production of pharmaceuticals and electronics. Molecular sieves are used to keep the environment dry so that moisture does not affect the products that are sensitive to moisture and can cause damage.

On the other hand, oxygen absorbers are designed to remove oxygen from the sealed containers and this makes the environment to be free from oxygen hence promoting the quality and freshness of the products. They consist of substances that have a tendency to react with oxygen, thus, they remove it from the surrounding environment. This makes oxygen absorbers very useful in the food industry because oxidation causes food to spoil, become rancid and lose its nutritional value. These absorbers work to remove oxygen which in turn helps to preserve oxygen sensitive food products for a longer time.

Silica Gel vs Molecular Sieves: Choosing the Right Desiccant

There are several factors to consider when making a decision regarding the use of either silica gel or molecular sieves for moisture control. Two of them involve efficacy in moisture absorption and merits versus demerits.

Efficiency in Moisture Absorption

Both molecular sieves and silica gel can act as desiccants; however, molecular sieves can efficiently hold more moisture than silica gel because of the internal structure of the pores. The uniformly sized pores of the molecular sieves can only absorb water molecules of certain sizes, thus allowing for faster dehydration. Silica gel on the other hand, although effective, is less efficient due to the irregularity of the pore sizes. This property of molecules doling out water to a unit weight of the molecule is stronger in the case of molecular sieves than silica gel. The ability of molecular sieves to absorb lots more water is enhanced by the fact that they are manufactured from zeolite which tends to be manufactured in perfected and correct pore sizes to assist in optimal water absorption.

Advantages and Limitations

Silica gel is inexpensive, simple to implement desiccating agent, readily available and can be reused by heating to drive out water moisture. Its common applications include food bags, garments and electronic items to name a few, where moisture needs to be controlled but is not of utmost importance. But in some applications this type of medium may be less effective than molecular sieves, especially those which require moisture to be controlled at a high level or moisture would cause the product to deteriorate significantly.

In contrast, they are more costly compared to silica gel but have moisture absorbed capacity more than silica gel and efficiency in all aspects. There are instances that these materials are warranted for instance where high level of moisture control is needed such in pharmaceutical applications where even little moisture affect the stability and effectiveness of the drug or in the electronics industry where moisture leads corrosion and failure of delicate parts. Because of their uniformly sized pores, moisture molecules in them can be absorbed such that only the contamination is removed making these materials preferable where moisture level in order to maintain product quality is of high importance.

Pros and Cons Across Different Industries

The use of desiccants and oxygen absorbers offers various advantages and disadvantages across different industries. Understanding these pros and cons can help businesses make informed decisions when choosing the best preservation methods for their products.

Food and Beverage Industry

Desiccants and oxygen scavengers are some of the quality enhancement techniques that most companies in the food and beverage industry resort to adopt. Particularly, silica gel packets and molecular sieves can avoid the effects of moisture by collaborating with mold problems and food spoilage, while the oxygen absorbers can counteract the amount of oxygen and keep oxygen-sensitive food items fresh.

Nevertheless, the employment of these packaging solutions still has certain limitations in the food industry. To illustrate, silica gel beads or molecular sieve pouches may present a choking hazard if they are swallowed by mistake. Furthermore, oxygen-absorbing technologies may not always be appropriate for everybody’s specific needs since there are foods which do not stand a complete lack of oxygen in them for the sake of the product’s quality.

Pharmaceuticals and Electronics

Moisture and oxygen control are key and should be ensured in the manufacturing of products in the pharmaceutical and electronics industries. Mole or molecular sieves are important as they show a better tendency in absorbing moisture compared to silica gel and are thus ideal in these industries.

Nevertheless, the use of desiccants and oxygen scavengers in these industries also calls for caution. In the pharmaceutical sector, all packaging materials have to go through regulatory agencies to approve their safety and compatibility with the drugs. In the electronics field, the use of desiccants and oxygen scavengers has to be adopted since there will be a need to control ventilation so that there is no overheating and other related problems.

| Preservation Method | Industry | Pros | Cons |

| Silica Gel | Food and Beverage | Cost-effective, easy to implement, reusable through heating. | Potential choking hazard; less effective for high moisture control needs. |

| Pharmaceuticals | Simple implementation for general moisture control. | Less effective in environments with high moisture control requirements. | |

| Electronics | Widely used in general electronic packaging. | Less efficient moisture absorption compared to molecular sieves. | |

| Molecular Sieves | Pharmaceuticals | High moisture absorption efficiency; ideal for maintaining drug stability. | Higher cost; requires precise manufacturing to achieve optimal performance. |

| Electronics | Excellent moisture control; prevents corrosion and component failure. | Costly and may not be necessary for low moisture environments. | |

| Oxygen Absorbers | Food and Beverage | Protects against oxidation and spoilage of sensitive food products. | Not suitable for all types of foods; potential choking hazard. |

| Cosmetics | Extend shelf life by eliminating oxidative reactions. | Limited by product requirements for oxygen levels. |

Partnering with Jalon for Advanced Preservation Solutions

For industries looking for improvement in the product’s life and better quality control, Jalon has advanced desiccant solutions. With a vast amount of experience and in pursuance of perfection, Jalon offers bespoke solutions to specific moisture and oxygen requirements. Work with us further so that we can use our innovative technology for the better preservation of finished products within the sphere of food, pharmaceuticals, and electronics.

Conclusion

When deciding between the three, silica gel, molecular sieves, and oxygen absorbers, it is crucial to consider the needs of your products and the standards of your niche. In this way, the businesses will be able to understand the advantages and disadvantages of each option and the effects that they have on the environment so that they can make the best decision in order to preserve their products.

In conclusion, the application of desiccants and oxygen absorbers can minimize waste, enhance the shelf life of products and preserve the quality and authenticity of products in different sectors. When these preservation methods are adopted in packaging and storage systems, companies will be in a position to enhance customer satisfaction, cut costs and help in the conservation of the environment.