Introduction to Desiccant Dehumidifiers

Have you ever stopped to think how a desiccant dehumidifier operates? Dehumidifiers are the most useful because with the help of these devices one does not have to worry about the humidity levels in a house, office, or any industrial area for that matter. In contrast to standard compressor dehumidifiers that operate on refrigeration principles to eliminate moisture from the room air, the mechanism of desiccant dehumidifiers revolves around the use of sorption materials. In this very detailed essay, we will examine how these dehumidifiers work, what parts of these dehumidifiers, prayers and advantages do they have compared to others types of dehumidifiers.

Core Components of a Desiccant Dehumidifier

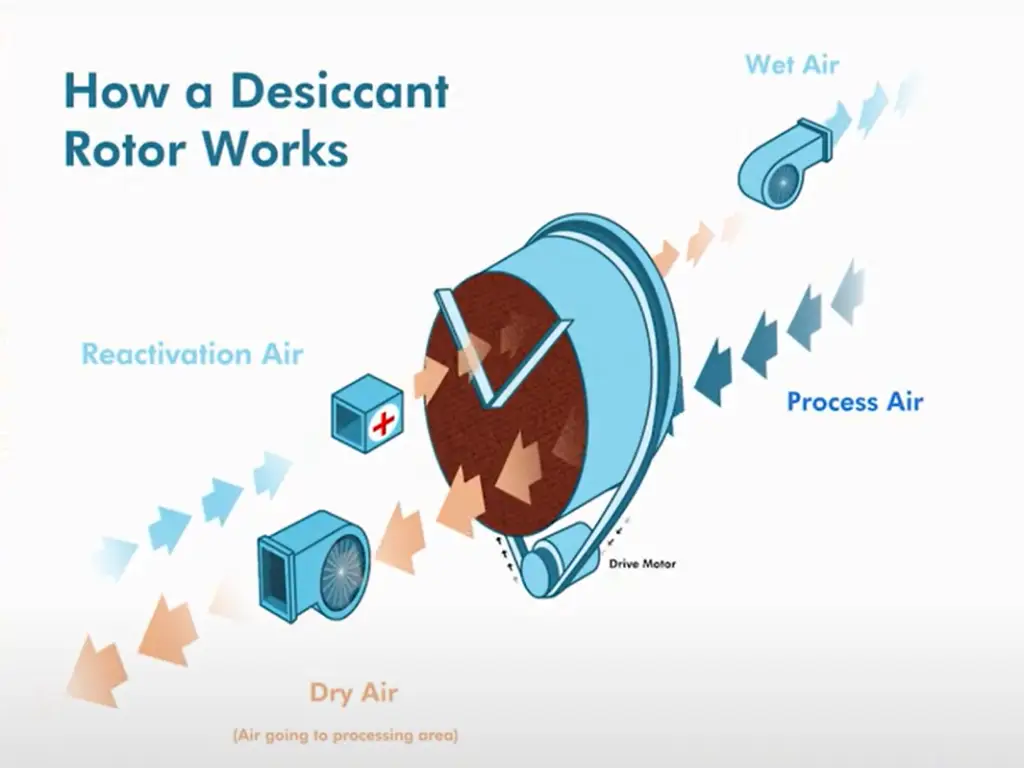

Desiccant Wheel

Desiccant wheel, or rotor, is the most important component within the desiccant dehumidifier system. The component is in cylinder shape and it facilitates the process of dehumidification. The surface of the wheel is covered with an innovative material which has the remarkable capacity to sorb and retain water molecules from the atmosphere, usually silica gel or zeolite. As it operates, the desiccant wheel enhances the exposure to the humid air of desiccant material that has not been saturated with water so that moisture absorption is maximized and eliminated moisture is sustained effectively.

Blower and Airflow System

The blower and airflow system are quite significant parts that aid the operation of the desiccant dehumidifier by adjusting its airflow. The blower sucks humid air from the surroundings, and pushes it to the rotating desiccant wheel. As the air moves a humid cloth, placed in the disc gets dried as it sucks the moisture from the air. This dry air is then introduced to the room, so it is expanded to make the environment cooler or easier to control.

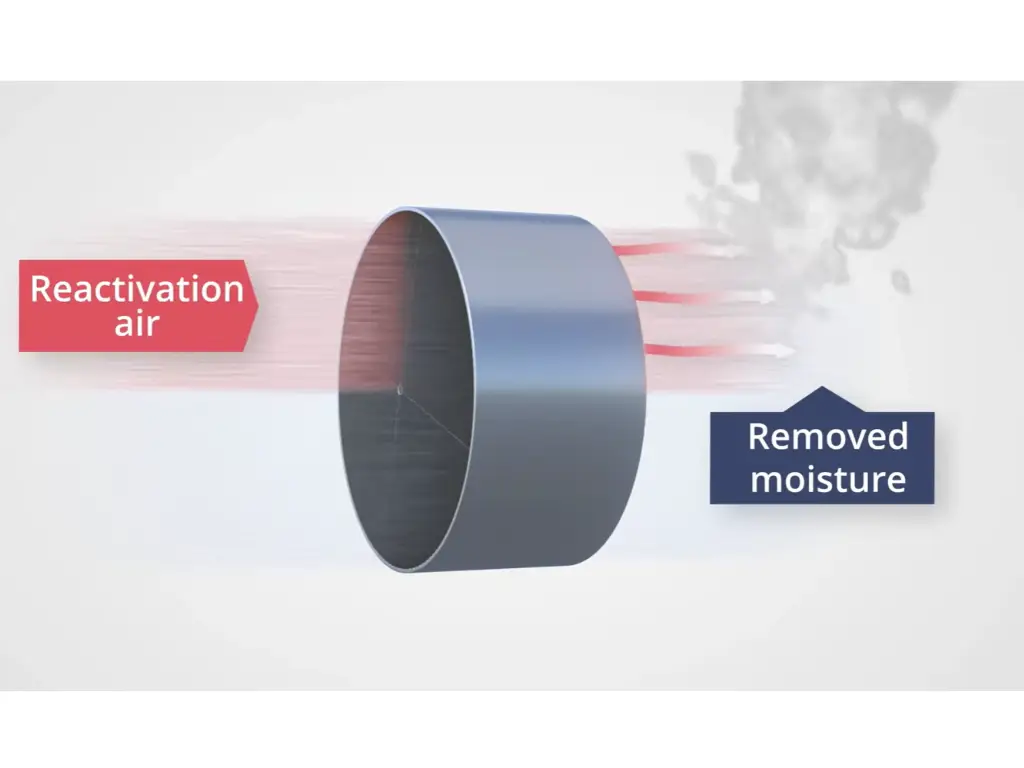

Heater and Energy Consumption

In order to maintain the efficiency of the desiccant wheel, there is a heater which is normally employed to regenerate the mass of the desiccant which has become saturated. The regeneration phase consists of subjecting the saturated powder into direct heated air injection all in a bid to dry the absorbed water thus refreshing the desiccant material. This regeneration cycle is very important regarding the working of the dehumidifier. There should be caution, however, that the heating element does consume energy and therefore the desiccant dehumidifiers are slightly more energy-extensively low than the compressor dehumidifiers.

Understanding the Desiccants Used

Types of Desiccants

Desiccant dehumidifiers utilize the moisture-absorbing ability of desiccants. The most popular types of sieves and adsorbents include zeolite and silica gel. A highly porous and water- absorbing material which is composed of silicon dioxide is called silica gel. Zeolite, however, is a mineral composed in nature with a certain crystalline structure that enables it to absorb and hold water molecules efficiently. It is safe to say that both silica gel and zeolite do not produce toxins, smell and can be used more than once and therefore are the best options for desiccant dehumidifiers.

Properties and Benefits of Silica Gel and Zeolite

Silica gel and zeolite are desiccants highly used in desiccant dehumidifiers due to their outstanding properties. These materials have some roughness with respect to their surfaces which is large compared to their volume and this enhance the moisture absorption. They also perform well within extreme temperature ranges and within different humidity levels. Inevitable regeneration process allows more moisture sorption to take place as it involves heating up the saturated material With regard to moisture sorption, the lengths of their work depend on those factors; the adsorption materials themselves and the potential of the silica gel to attract and hold onto water.

It is also interesting to add here that zeolite is a subtype of molecular sieving agent which has efficient dehydrating agent utilized in desiccant dehumidifiers. Molecular sieves made up of zeolite have significant advantages when it comes to the absorption of moisture than the other absorbers. This is attributed to their mesoporous structure and their relatively high internal area which helps to absorb water only but reject wider molecules. Depending on their geometrical setup, molecular sieves have been shown to retain their adsorption properties even when exposed to harsh environment conditions which makes them a good candidate for efficient and long lasting dehumidification in different applications.

| Property/Feature | Silica Gel | Zeolite |

| Composition | Made of silicon dioxide | Naturally occurring aluminosilicate minerals |

| Moisture Capacity | High moisture absorption | Excellent moisture retention |

| Regeneration | Typically regenerated by heating | Regenerated by heating |

| Operating Range | Effective across wide temperature ranges | Stable at high temperatures |

| Durability | Reusable, non-toxic | Long-lasting, highly stable |

| Applications | Used in various consumer goods, electronics, and pharmaceuticals | Used in industrial applications for air and gas drying |

| Advantages | Non-corrosive, easy to handle | High resistance to chemical reactions and thermal stress |

| Disadvantages | Loses effectiveness when saturated | Higher cost compared to some other desiccants |

The Principle of Operation

Being an advantageous mix between the cycle of air and the rotating desiccant wheel, the desiccant dehumidifier also comprises dehumidification. This type of dehumidifier uses a sucking blower to pull in the humid or cold air to the rotating desiccant, which makes use of the moisture present in humid or cold air. The moist air is absorbed in this case at the molecular level, whereby the water molecules get embedded into the surface of the desiccant. As further rotation of the wheel takes place, air which has been dried is forced out of the chamber and into the occupants’ room, lowering humidity levels.

A regeneration cycle, however, must be implemented in order to make the desiccant wheel efficient. A desiccant material becomes old when it becomes saturated, and this means it cannot hold in more liquid. This involves using a warmth stream most of the time heated by the heater that is installed in the unit and that possesses moisture in the desiccant. The regeneration zone allows for high temperatures to evaporate water molecules that have been attached to the desiccant, thus restoring its desiccant effect. Therefore, such a desiccant dehumidifier has the possibility of running a dehumidification as well as a regeneration operation in addition to the unitary vapor compressor system, thereby aiding in effective management of the desired humidity levels within that space.

Advantages of Desiccant Dehumidifiers

The performance of desiccant dehumidifiers is impressive due to the fact that they can be operated in different climatic conditions. Desiccant dehumidifiers, on the other hand, perform optimally even at low temperature since they do not rely on cooling coils, which is a common feature of the compressor dehumidifiers. This makes their use very convenient in colder region or winter months when other dehumidifiers may be unable to bring out the intended moisture levels in the air. The temperature variation does not influence the water vapour adsorption performance of the adsorbent.

Desiccant dehumidifiers tend to perform remarkably well in low temperature conditions. Whereas compressor dehumidifiers do not work well, or even stop to work altogether when it is excessively cold outside, and such temperatures exceed a certain level, desiccant dehumidifiers do not reduce effectiveness as much. The process of adsorption which involves the appealing forces of molecules of water to the desiccant material is not hindered by low temperatures. In such settings, areas like basements & storage that require thumping or excess water removal even in such shady environments, or Constant temperature working areas of industries whose processes are affected by temperature fluctuation & humidity will benefit from the use of desiccants.

Applications and Uses

Industrial and Commercial Uses

Desiccant dehumidifiers are used in a variety of industrial and commercial activities. These Products are also used in nearly every area of the manufacturing, storage, and food processing industries where humidity control is required. The need for moisture control in non-breathing containers that house moisture-sensitive products in the pharmaceutical industry is well accommodated by desiccant dehumidifiers. Additionally, they find varied applications in industries like paper archiving, clinics, and museums where artifacts and documents are protected from the adverse effects of high humidity.

Household and Personal Applications

Although desiccant dehumidifiers are most commonly identified with use in industrial and commercial environments, they have quite useful applications at home level as well. Desiccant dehumidifiers are small portable units that are capable of managing humidity in houses, apartments, and small workstations. They are especially necessary in moisture prone places like basements, bathrooms, and laundry rooms where accumulation of excess moisture often leads to development of molds and unpleasant smells. Desiccant dehumidifiers have also been used to avoid humidity damage to moisture-sensitive electronics, paintings, and musical instruments.

Comparison with Compressor Dehumidifiers

Desiccant type dehumidifiers have many benefits over the traditional compressor dehumidifiers in terms of moisture control. The conventional dehumidifiers use cooling coils while compressor type dehumidifiers’ main function is condensation of moisture by the cooling. That is why these two types of devices are designed to work well at different temperature ranges, where desiccant dehumidifiers can be use effectively in lower temperatures compared to compressor dehumidifiers. They also tend to be anyway quieter and more energy efficient than the others as compressor and refrigerant are not included in design. Still, one should keep in mind that compressor dehumidifiers may be more preferable in large area or extremely humid environments.

Common Challenges and Solutions

Energy Consumption

One of the cons of using desiccant dehumidifiers is the energy consumption associated with that method. The heating up of the saturated substance, which is the regeneration process, consumes a lot of energy. This increases the operational costs of the desiccant dehumidifiers as compared to the compressor dehumidifiers. However, hyperefficient desiccant dehumidifiers have been developed owing to technology. In some models, heat is captured and used to pre-heat the moist air, thus, minimizing energy requirements.

Ventilation and Airflow Issues

Ventilation and airflow are some of the key components and processes that are required in the operation of a desiccant dehumidifier. In case the device has been positioned in an area where there is limited airflow or ventilation, it would be extremely difficult to remove any moisture that is present in the air. This leads to inefficiencies and prolonged dehumidification processes. On that note, it is necessary that the dehumidifier, especially the portable type, is placed on a well-aerated area with obstruction free and high or low airflow relative to the machine. In addition, if there are any air filter elements present on the device, such fixtures have to be cleaned regularly to avoid unnecessary air flow in the unit.

Elevate Your Dehumidification Efficiency with Jalon

Opting for the Jalon desiccant dehumidifiers brand is a decision to work with leading manufacturers of zeolite molecular sieve all over the globe. Thanks to over 20 years of devoted effort and an ability towards producing high-quality ISO certified molecular sieves, Jalon guarantees wonderful and environmental friendly products. The company’s all-round designs and cutomised project study serve a wide spectrum of industries, from pharmaceuticals to natural gas. Thanks to the company`s global reach and rapid delivery of desiccant dehumidifier system, which provides the company with scope of orders aimed at specific humidity control condition, your operations run as intended. Advanced innovation labs and well trained scientific staff of Jalon will always be available at your services to ensure growth of your new business.

Conclusion

In summary, desiccant dehumidifiers are effective in filling the gaps, which exist in other methods of humidity control, in more than one type of application. In isolation, these machines work by using moisture reactive materials known as desiccants to eliminate the saturated air present in a room in a more comforting manner. Therefore, it is very important to get the touch and the feel of the desiccant dehumidifier, its key elements, operating principles, advantages and the like to make the best choice in terms of the humidity issue.