Introduction to Desiccant Packs

Have you ever wondered how long desiccant packets are effective? Some of us may have used silica gel or clay desiccant leftover packets which normally accompany product boxes. These small packets are useful in preserving our items from moisture and other forms of degradation.

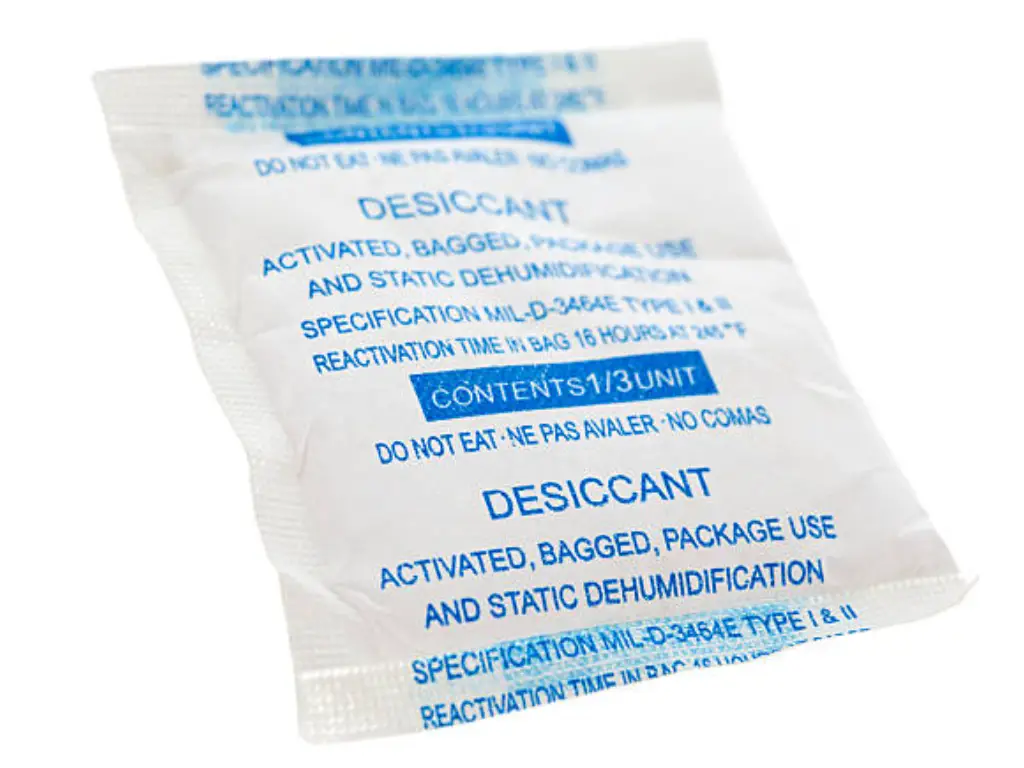

Desiccant packs, also referred to as moisture absorbing pouch, are smaller packages containing moisture absorbing agents. They are available in several different formats some of which include granules of silica gel, clay desiccants, and molecular sieves. These packagings are common in many products that we use in our daily lives including electronics, medications, foods and even clothes. Such packs ensure that the surroundings are dry, thus preventing objects from getting affected by oxidation, dampness and other effects of water.

Understanding the Lifespan of Different Desiccant Packs

In case of the lifespan of desiccant packs, there cannot be a single answer. The effective period of efficiency of these moisture adsorbing sachets is influenced by different factors, including the kind of desiccant material being used, the packaging size, and the environment in which they are placed. Let us examine some of the most common desiccants and how long do they usually last.

Factors That Affect Desiccant Longevity

There are many parameters that assist to ascertain desiccant packets longevity. The most important is the humidity of the surrounding air. The goal of desiccant pouches is to take up the moisture from the atmosphere, thus higher humidity will lead to a quicker saturation of the pouches. There are some other considerations with influence such as temperature. Extreme temperatures (too hot and too cold temperatures) will also affect their ability to absorb moisture. Moreover, desiccant packs dimension as well as quantity of the desiccant material inside the pack also determine the drainage duration of the pack effective water vapor absorption and retention.

Comparison of Silica Gel, Clay Desiccants and Molecular sieve

Silica gel can be found in almost every packaging as one of the most popular desiccants. They are actually small, transparent beads made from porous silicon dioxide. A silica gel packet may stay usable from 2-3 months up to about a year, depending on the environment it is placed in. Another common type is the clay based desiccants that include montmorillonite clay. They are regarded for their high moisture retention and can be effective for several months to a year. However, concerning especially molecular sieves, these are compounded zeolites that have a more specific absorption mechanism that is effective to moisture. These can extend longer than silica gel and clay desiccant, often remaining effective up to 2 years under proper storage conditions.

| Desiccant Type | Typical Effective Lifespan* | Regeneration Conditions |

| Silica Gel | 3-6 months | 120-180°C for 2-3 hours |

| Bentonite Clay | 4-8 months | Not recommended |

| Molecular Sieve (4A) | 12-18 months | 200-315°C for 2-3 hours |

*Actual lifespan may vary depending on storage conditions and specific product specifications.

Ideal Storage Conditions for Desiccant Packs

It is therefore important to store the desiccant bags in the right manner to ensure that they are effective. If the desiccant packs are stored properly, they will continue to pull in moisture and protect your products from humidity for an additional time. The best conditions for storage of the desiccant packs include storing them in a cool dry area with no direct sunlight and in extreme temperatures. They should also be kept in an airtight container or sealed packaging to avoid them getting in contact with moisture in the air when not in use.

However, there are some temperatures and conditions that are not recommended for the use of desiccant packs to help them last longer. High temperatures can lead to the degradation of the desiccant material and hence its ability to absorb moisture. Likewise, low temperatures can harm the structure of the desiccant beads or crystals, which are used in the process. Bathrooms and kitchens are also unsuitable for storing the desiccant packs because the high humidity in these areas will cause the packs to become saturated very fast. To maximize the shelf life of your desiccant bags, it is recommended that you store them in a cool, dry place with little fluctuations in temperature.

Signs That a Desiccant Pack Needs Replacement

One of the most noticeable signs of imminent resignation of the pack is the inconsistency in the color of desiccant beads or desiccant crystals. Several types of desiccants contain colour changing indicators which reversibly change the color of cobalt chloride, from blue to pink when a certain amount of excess moisture is absorbed inside of the indicator. In this case, the presence of any color change is a prompt that the dexicant pack requires immediate replacement. In the same vein, if the desiccant bag appears to be squishy and lumpy with visible water droplets present within then the bag has probably reached its optimum level of moisture absorbing.

Also the observation of changes in the condition of the items an active desiccant pack is protecting can also help determine when a desiccant pack needs to be replaced. If you’ve seen rust, mildew, or moisture damage on your things in the presence of a desiccant bag, then it could possibly mean that the desiccant is no longer useful.

When it comes to cleaning and replenishing desiccants that come in molecular sieve desiccant packs for applications in industrial and food processing industries, the need for replacement may not easily be seen. This is because molecular sieves do not usually contain colour change indicators, you will use other approaches to help you determine saturation of the beads. One way involves focusing on the relative humidity of the air in the region where molecular sieve packs are used. If you still see loss of desiccant but the packed humidity keeps rising, it is close to high time you bought more packs to replace those ones.

How to Extend the Lifespan of Desiccant Packs

Although desiccant packs do eventually require some replacing, concentrating as much as possible on their useful life can come in handy with the types of moisture absorbers. Some simple usage practices and regeneration techniques will help you extend the tousle effective life of your desiccant bags.

Proper Usage Practices

One of the key factors in extending the packaging lifespan of the desiccant packs is correct application. If you are using desiccant bags, ensure that you enclose them inside of the sealed container or packaging of the items that need protection. This aids moisture control within the soaked items or desiccants, thus eliminating the fast saturation of the desiccants. In addition, avoid unnecessary exposure to the opening and or closing the container or the purchasing package overly often as this will introduce moist air internally and decrease the desiccant pack’s usefulness.

Regeneration of Molecular Sieve

Molecular sieves, unlike silica gel and clay desiccants, can be regenerated to create a reusable desiccant. Regeneration is a step that helps to restore the sieve by exposing the material to heat at 400-500°F (200-260°C), with the major aim of getting rid of the moisture that has been trapped in the sieve. This process can be performed in a specialized regeneration oven or a standard oven with sufficient extraction. Reusable and economical in the long run, regeneration of molecular sieve desiccant packs helps to extend the scope of activity of such packs.

The Role of Packaging in Desiccant Efficiency

Packaging plays an effective and protective barrier and also extends the useful life of the desiccant packs. The appropriate packaging operates to ensure dry storage and also to shield the desiccants from extrinsic conditions thereby increasing their durability.

Since desiccants are most effective when kept in airtight containers or sealed bags, then packaging is very important. These containers prevent moisture from entering and keep the desiccant focused on absorbing moisture from the enclosed space. Humidity sealable bags such as foils or multilayered plastic bags act as a preservative cover suitable for protecting against any form of contact with vapor within the storage space and thereby preserving the working efficiency of the desiccant for longer periods.

Also, it is notable that the effectiveness of the desiccant packs is affected not only by physical properties such as the type of packaging material but also by the size and quantity of the packs used. It is necessary to use the appropriate pack and quantity of the desiccant bags depending on the size of the container and the moisture protection needed. Undersizing the consumption of desiccants or using lesser packs may lead to unsatisfactory moisture absorption. On the other hand, using excessive desiccants may lead to wastage and unnecessary cost escalation. It is thus possible to optimal use of desiccant packs and their packaging in order to avoid excessive costs while ensuring the greatest effectiveness.

Best Practices for Using Desiccant Packs in Various Industries

Electronics Industry Applications

In the electronics industry, rainfall is the prime hindrance leading to rust, electrical shortries, and poor performance. In order to distribute and stock electronics components, devices in addition to equipment, desiccant packs are of great significance as they assist in preventing the risk of moisture damage during storage and transportation. In the case of desiccant bags being used in electronics packaging, it is important to properly determine the material and size of the desiccant taking consideration the sensitivity of the components and the determinant conditions of storage. There is favorable use of silica gel or molecular sieves in electronics since they are good keeping the materials dry.

In The Pharmaceutical Industries

Desiccant packs are especially relevant in the pharmaceutical business where moisture sensitive medications need such packaging to be effective and stable. Active ingredients will not deteriorate and medications will be safe and effective for patients when such desiccant bags are used. There are clear rules on the use of these desiccants in the said industry as a great concern is put on those materials. For example, all desiccants must be made of pharma-grade materials like silica gel and molecular sieves which have pre-determined requirements. Moreover, all other components used together with desiccant packs also need to be suitable for the drug and the regulations set on pharmaceuticals. There is also such a thing as a reason to document and validate the desiccant used in the appliance so as to avoid compromising on quality and the patient’s safety in the pharmaceutical field.

Partnering with Jalon for Professional Desiccant Solutions

If you are searching for high-quality and reasonably priced desiccant solutions, more so for desiccants in the form of a molecular sieve, look no further than Jalon. Based on our broad experience in moisture management, we can develop desiccants which will suit your particular industry. Our experts can assist in selecting the most appropriate desiccant, optimizing packaging, and ensuring product validity no matter whether you belong to the electronics, pharmaceutical or manufacturing industries. Contact us today to learn about how we can assist you in preserving your precious items from the threat of moisture.

Conclusion

In conclusion, the lifespan of desiccant packs depends on various factors, including the type of desiccant material, storage conditions, and usage practices. By understanding how long do desiccant packs last and implementing proper storage and usage techniques, you can maximize their effectiveness and extend their longevity. Whether you’re using silica gel, clay desiccants, or molecular sieves, these tiny packets play a crucial role in protecting our belongings from moisture damage.