We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

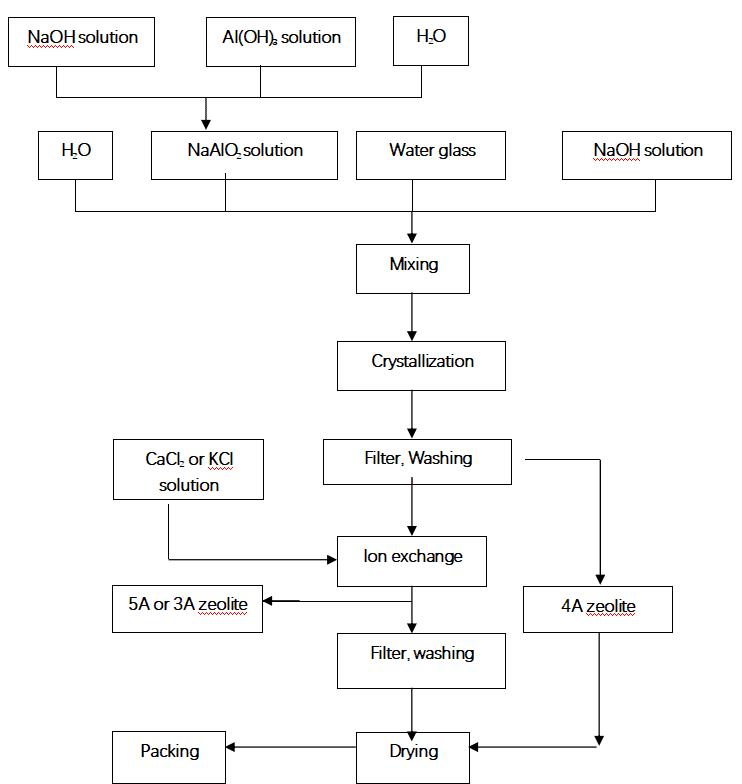

Process Description:

Synthetic zeolite powder 3A and 5A are transformed from synthetic zeolite powder 4A by ion exchange, and synthetic zeolite powder 10X is transformed from synthetic zeolite powder 13X by ion exchange. Since the processes of making synthetic zeolite powder 4A and 13X are nearly the same.

The manufacturing process of synthetic zeolite powder 4A can be divided into material preparing, mixing, crystallization, filtering, washing, drying and packing. The production method is called hydrothermal synthesis.

The raw materials for manufacturing synthetic zeolite powders are the same including NaOH, Al (OH)3, water and water glass (Na2SiO3 solution. After mixing the Al(OH)3 solution and NaOH solution by certain rate, NaAlO2 solution is generated. Then NaAlO2 solution, NaOH solution, Na2SiO3 solution and water are mixed by certain rate in the mixing tank. After heating the tank for a certain time, we got the raw 4A crystal. Then the 4A crystal is put into the filter tank for filtering and washing, drying and packing.

For the producing process for synthetic zeolite powder 5A and 3A, it is much the same with production of synthetic zeolite powder 4A. After getting the 4A crystal, it is transferred into the ion exchange tank. If want to get synthetic zeolite powder 5A, we put the CaCl2 solution in iron exchange tank. If want to get synthetic zeolite powder 3A, we will put the KCl solution in ion exchange tank. After heating the ion exchange tank, the solution is filtered, washed, dried and packed. Finally we get the final 5A or 3A synthetic zeolite powder.

The manufacturing process of synthetic zeolite powder 13X is same with 4A synthetic zeolite powder, only the mixing rate is different. After getting 13X crystal, we put the crystals into the ion exchange tank, and also put the CaCl2 solution in, after heating, filter, washing, drying and packing, we got the final synthetic zeolite powder 10X.