We value your privacy

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

No cookies to display.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

No cookies to display.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

No cookies to display.

Jalon is one of the best zeolite molecular sieve manufacturers in China and around the world. We have continued to offer incredible options to all our customers for more than 20 years. We provide molecular sieves of the best quality to accurately cater to your needs.

Our molecular sieves beads and pellets are applicable in different industries, some of which include medicals, refineries, natural gas, coal chemical, and oxygen generation among others. Our expertise in the supply of quality molecular sieves has allowed us to work with clients from all over the world.

We pride ourselves on providing reliable and quality molecular sieve desiccant, which come in different sizes and shapes. By choosing Jalon as your trusted zeolite molecular sieve supplier, you can rely on our commitment to delivering high-performance products that drive your success.

We tailor your project with in-depth analyses, offering customizable solutions in pore size, material composition, surface treatments, and form. Our full-production-chain capability ensures the best performance for your unique needs.

We offer a wide range of grades, including A, X, and Z-type, catering to various separation and purification needs. Our diverse product portfolio ensures you find the perfect solution for your application.

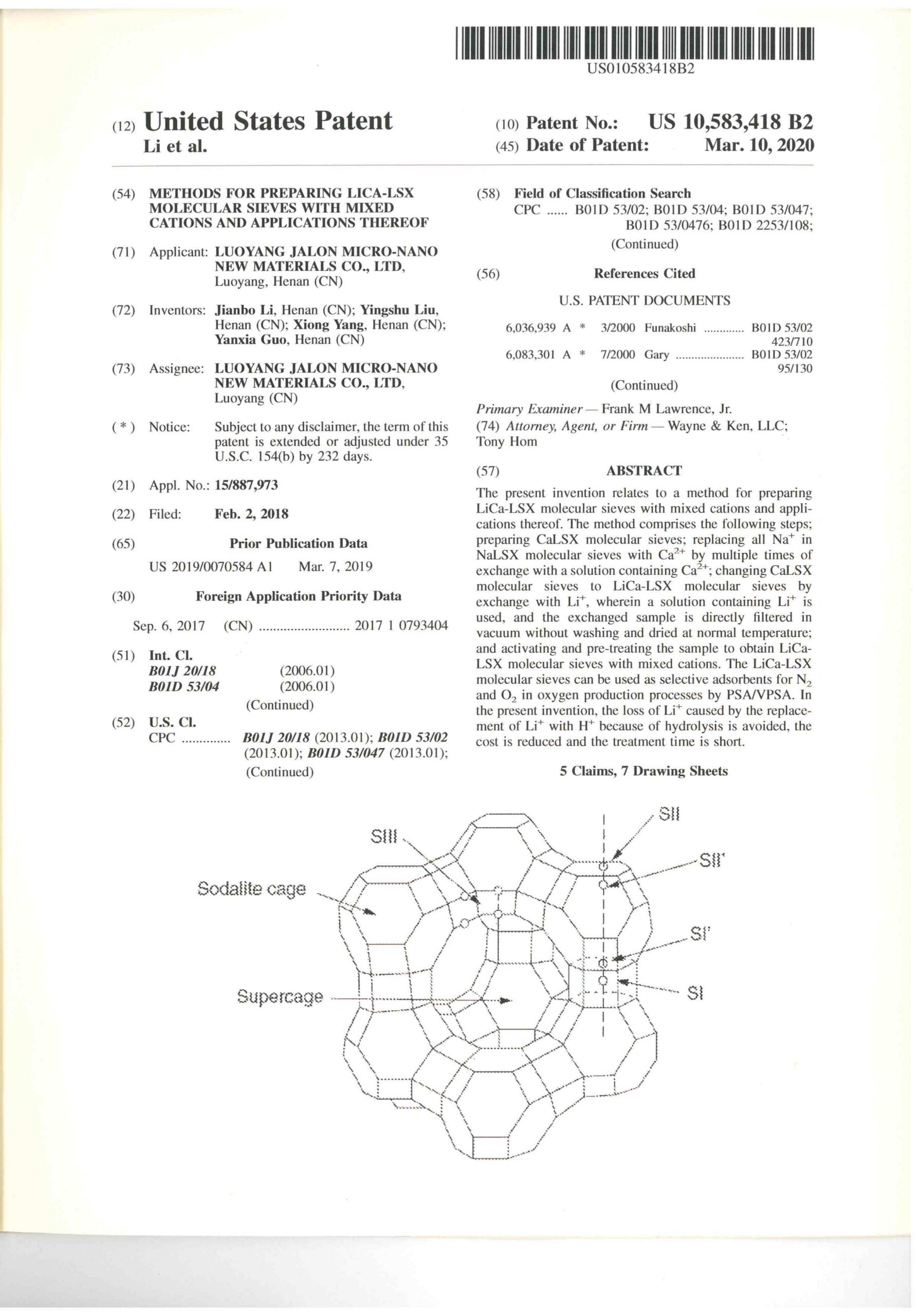

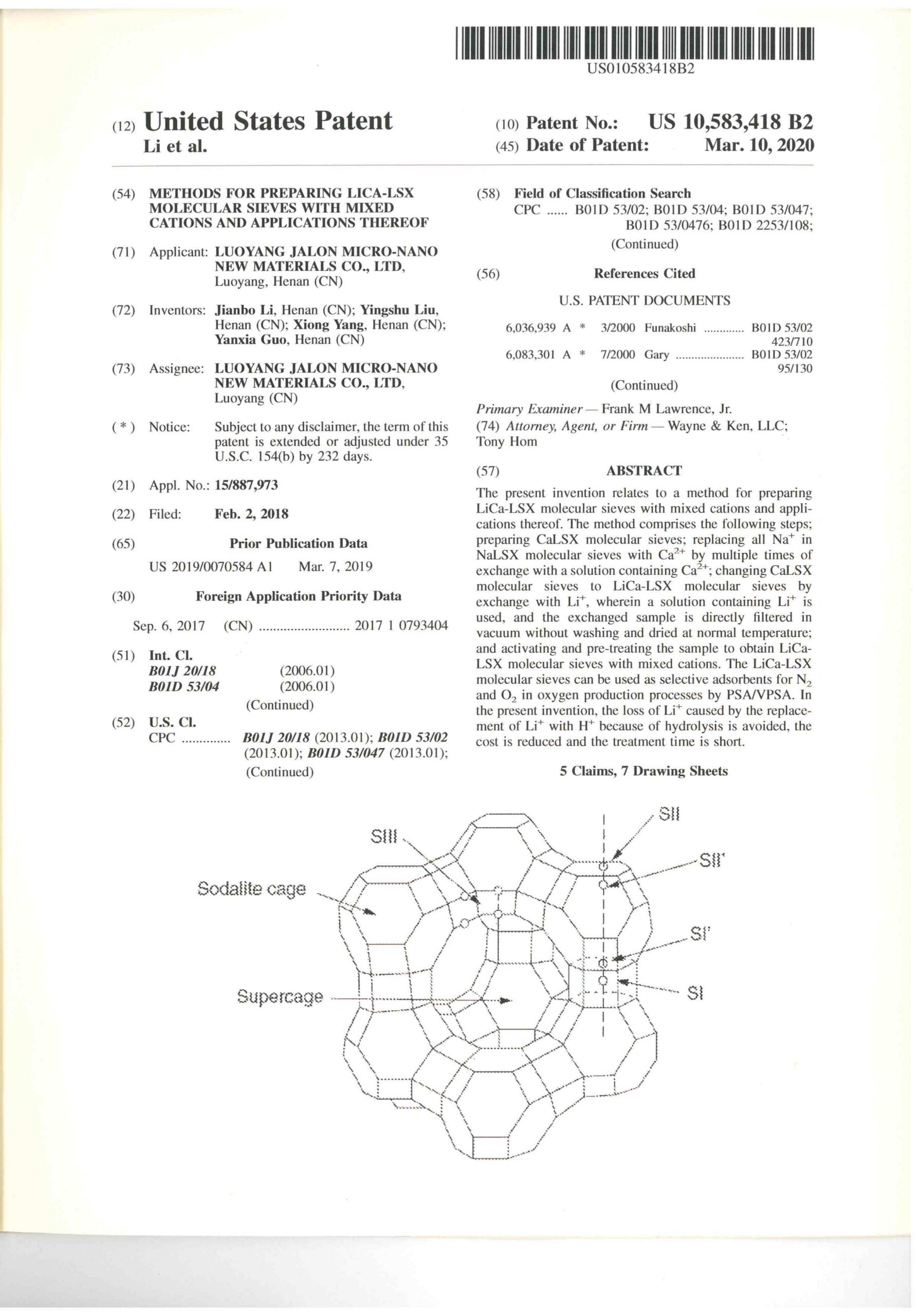

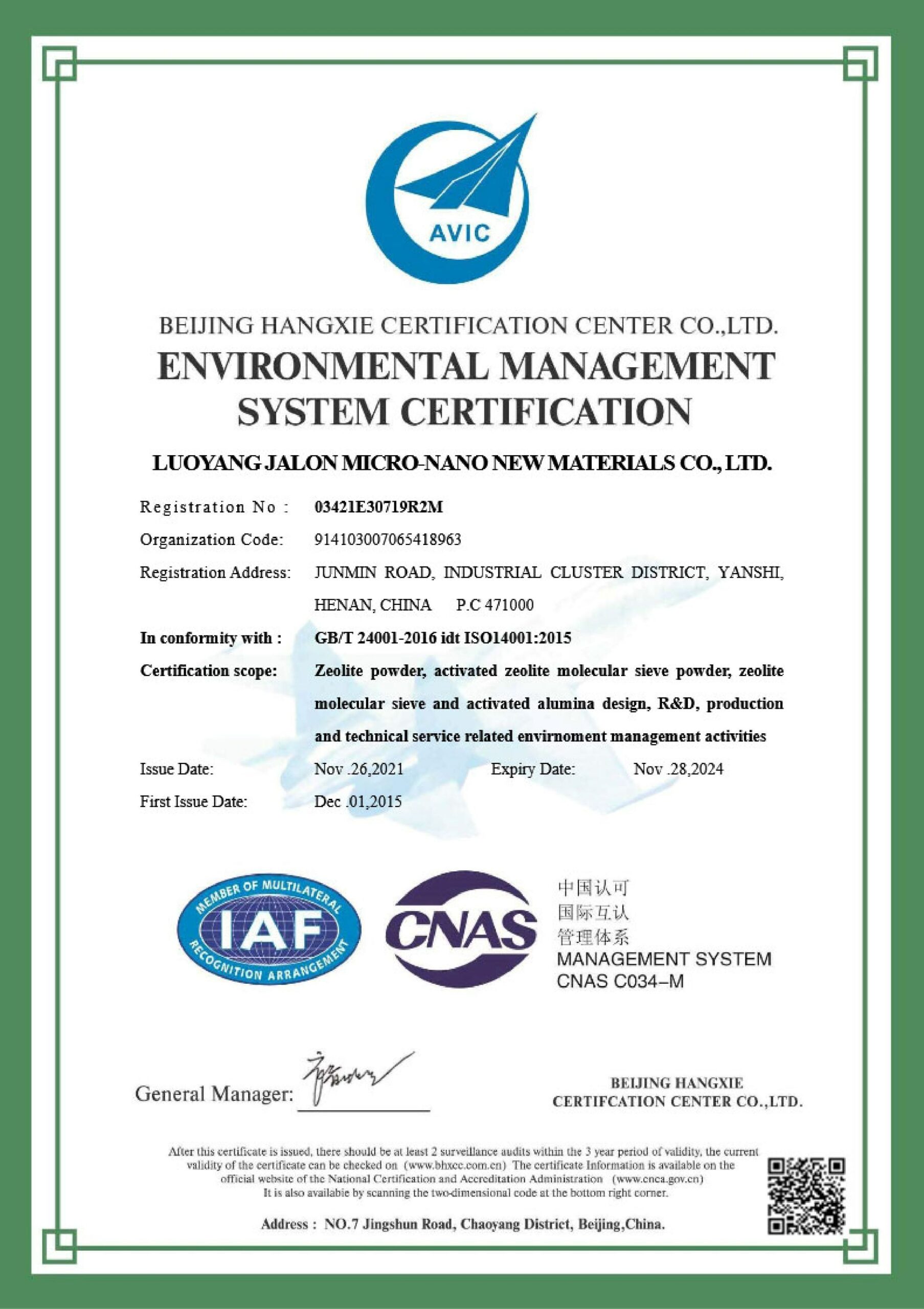

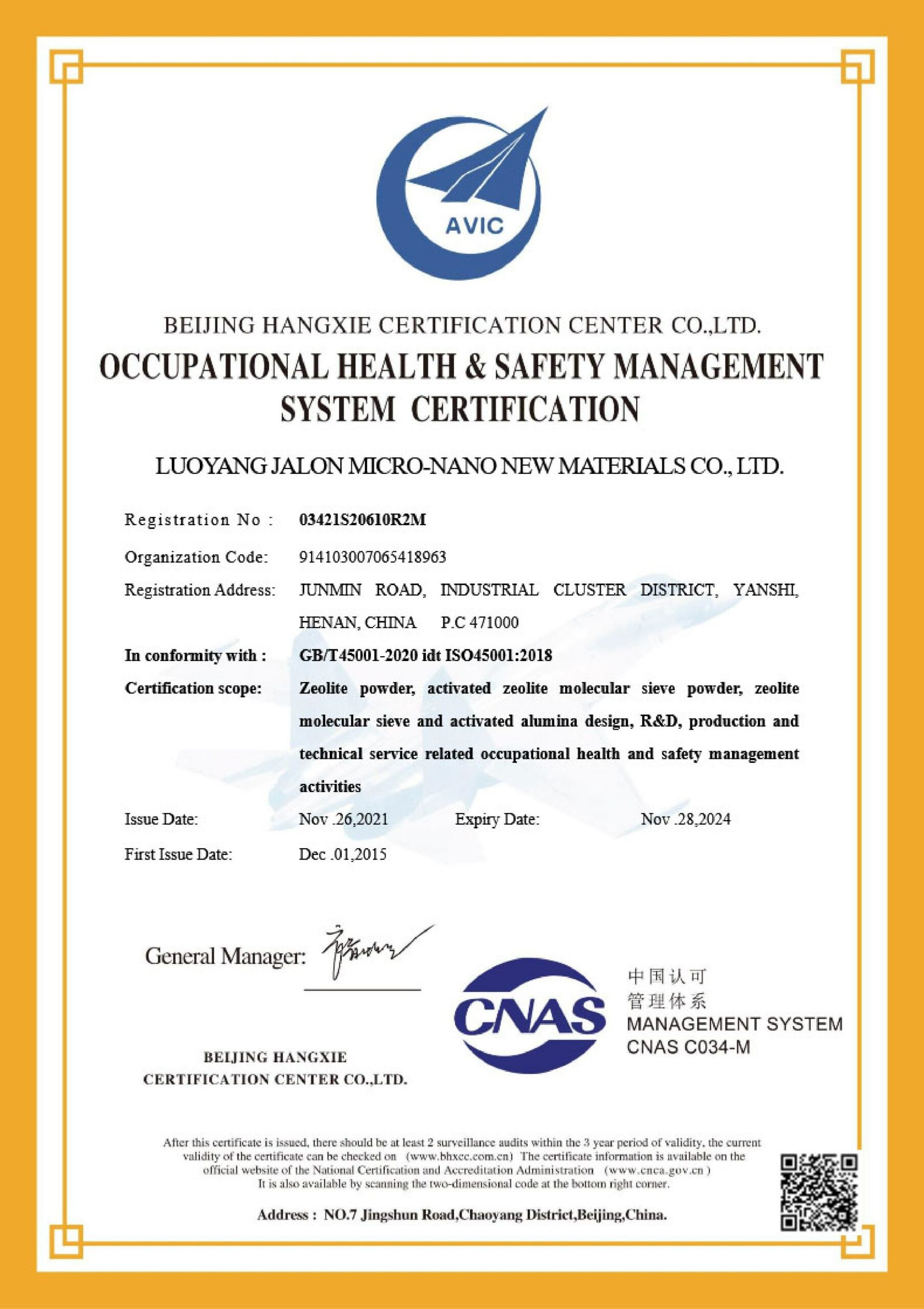

Our ISO 9001 and ISO 14001 certifications validate our adherence to the highest quality and environmental standards, ensuring consistent, reliable, and eco-friendly products.

Our vast production capacity, along with strategically located factories near ports and airports, enables us to quickly respond to customer demands and fulfill orders, ensuring fast and reliable delivery for your business needs.

We understand that your needs may vary, which is why we have no minimum order quantity requirement. This flexibility allows you to order exactly what you need for your specific application, without any unnecessary surplus.

With our worldwide partners and complete marketing network, we provide on-site or online engineering support, operation services, and troubleshooting for your entire project. Choose Jalon and benefit from our global presence and expertise.

Boasting the largest production capacity in Asia, our fully automated DCS-controlled production lines guarantee maximum safety, efficiency, and product quality. By leveraging advanced computer technology to monitor, operate, and manage the production process, we can ensure high levels of automation, minimize energy and raw material consumption, and ultimately deliver superior molecular sieve products to our customers.

Jalon’s proprietary manufacturing processes use the automated system production lines process control systems.Formed a complete industrial chain of adsorption materials, making the production of adsorption materials more intensive and large-scale.Jalon Company has passed ISO9001 certification, and having a complete and strict internal control system process. At the same time, The company has a provincial R & D center. And we cooperate with Jilin University and Beijing University of Science and Technology to improve product performance and develop new products according to customer’s special requirements. Besides our company values environmental protection. Here’s the production flow of molecular sieve:

Precise sieving, polishing, cooling, and rapid packaging (with various sizes and materials for chosen) under controlled low-humidity conditions (< 50%). This minimizes moisture adsorption, guaranteeing the lowest possible water content and ensuring that our molecular sieves consistently meet the most stringent industry standards for optimal performance.

We ensure consistent, superior performance by starting with the highest quality raw materials. Our vertically integrated production process, combining premium imported clay with internally-produced zeolite powder, allows for strict quality control throughout manufacturing, optimizing costs and guaranteeing unrivaled product quality and consistency.

Automated pneumatic valves and systems manage the exact sequence and proportions of each component. This ensures a uniform blend, crucial for consistent adsorption properties and material performance.

The pelletized granules are further processed in the forming phase, where they are precisely combined with synthetic zeolite powder, binders, and additives to form uniform spherical beads. This critical step guarantees that the beads achieve optimal adsorption efficiency and durability, ensuring the highest quality for demanding applications.

Jalon’s proprietary calcination process effectively removes moisture and organic additives while preserving zeolite integrity. This results in superior adsorption capacity, selectivity, and stability, making our molecular sieves exceptional for demanding applications.

Precise sieving, polishing, cooling, and rapid packaging (with various sizes and materials for chosen) under controlled low-humidity conditions (< 50%). This minimizes moisture adsorption, guaranteeing the lowest possible water content and ensuring that our molecular sieves consistently meet the most stringent industry standards for optimal performance.

We ensure consistent, superior performance by starting with the highest quality raw materials. Our vertically integrated production process, combining premium imported clay with internally-produced zeolite powder, allows for strict quality control throughout manufacturing, optimizing costs and guaranteeing unrivaled product quality and consistency.

Zeolites are crystalline aluminosilicates with molecular sieving attributes, which makes them being broadly used for catalysis, adsorption, and ion exchange applications. Jalon’s molecular sieves are engineered to provide superior adsorption capabilities, high selectivity, and excellent durability, making them the ideal choice for a wide range of industries. Our products are designed to help you optimize your processes, increase efficiency, and reduce costs. Here are the following zeolite powder uses:

Introduction

Molecular sieve 3A feature average pores measuring 3 angstroms (0.3nm), any molecules larger than 3 angstroms will be immediately sieved out. 3A mol sieves are widely used for specific needs in varied industries including ethanol dehydration, cracked gas dehydration, refrigerant dehydration, and natural gas dehydration among others.

Introduction

The diameter featured in 4A mol sieves comes in at 4 angstroms (0.4nm). This allows the sieve to easily exclude molecules with a larger diameter. Molecular sieve 4A is the preferred adsorbent for the static dehydration in a closed gas or liquid drying system, making them highly effective molecular sieves for water removal in various applications.

Introduction

We offer molecular sieve 5A designed and developed by the best in the business. Our 5A molecular sieves feature a diameter of 5 angstroms(0.5nm). This allows you to exclude any particles or molecules that have a larger size in diameter.

Introduction

Molecular sieve 13x is designed to ensure that its performance in an application is top-notch. The 13x molecular sieve features a diameter of 10 angstroms (1nm). This goes to show that all particles and molecules larger than 1nm will be excluded.

Introduction

We offer CAX molecular sieves designed and developed by the best in the business. Our Molecular Sieve CaX is the calcium form of the type X crystal and has a much larger pore opening than the type A crystals.Calcium X (CaX) and Calcium LSX (CaLSX) are the calcium-exchanged forms of the 13X and LSX type zeolites. It will adsorb molecules with a kinetic diameter of less than9 Angstrom (0.9nm) and exclude molecules of larger than 0.9nm.

Introduction

JALON Molecular sieve JLOX-100 series is designed for oxygen concentrator that has high-efficiency nitrogen adsorption, JLOX101 molecular sieve is a lithium X-type(LIX Zeolite) aluminosilicate crystal, adsorb nitrogen from the air while allowing the oxygen to pass get purified enriched-oxygen through the system pressure swing adsorption(PSA) in a medical oxygen concentrator devices. It has the characteristics of large nitrogen adsorption capacity, high nitrogen and oxygen separation coefficient, and easy desorption. Its nitrogen adsorption capacity is 2-3 larger than the A-type oxygen molecular sieve.

Molecular sieve is a kind of adsorbent or membrane material with uniform micropores, mainly composed of silicon, aluminum, oxygen and other metal cations. Its pore size is equivalent to the general molecular size, and various fluid molecules are screened according to its effective pore size. Zeolite molecular sieves refer to those natural and synthetic crystalline aluminosilicates that have molecular sieve function. Molecular sieves can be produced in various forms, including molecular sieve beads, pellets, and desiccant powder, depending on the specific application requirements.

In the world gas separation and purification is used in many industries.Molecular sieve is high performance adsorbent with excellent kinetic gas adsorption and separation capacity. Moleular sieve is widely used in various industries such as cryogenic air separation, PSA&VPSA oxygen generator, hydrogen purification, natural gas dehydration, ethanol dehydration, ethylene dehydration, propylene dehydration, ethanol dehydration, refrigerant dehydration, air break system, insulating glass, etc.

Zeolite molecular sieves are crystalline silicates or aluminosilicates, formed by silico-oxygen tetrahedrons or alumino-oxygen tetrahedrons connected by oxygen bridges to form pores and voids of molecular size. Cavity system, which has the characteristics of sieving molecules. However, with the in-depth research on the synthesis and application of zeolite molecular sieves, researchers have discovered phosphoaluminate zeolite molecular sieves, and the framework elements (silicon or aluminum or phosphorus) of zeolite molecular sieves can also be composed of B, Ga, Fe, Cr, Ge, I, V , Mn, Co, Zn, Be, and Cu, etc., and the size of the pores and cavities can reach 2 nm or more. Therefore, zeolite molecular sieves can be divided into silicon-aluminum zeolite molecular sieves, phosphorus-aluminum zeolite molecular sieves and framework heteroatom zeolite molecular sieves according to the composition of the framework elements.

Divided by channel size, zeolite molecular sieves with channel sizes less than 2 nm, 2~50 nm and greater than 50 nm are called microporous, mesoporous and macroporous molecular sieves, respectively. Due to its large pore size, it becomes a good carrier for large-size molecular reactions, but the pore wall of the mesoporous material is amorphous, so that its hydrothermal and thermal stability cannot meet the harsh conditions required by petrochemical applications.

Because it contains metal ions with a low electricity and a large ion radius and water in a combined state, water molecules are continuously lost after heating, but the crystal skeleton structure remains unchanged, forming many cavities of the same size, and the cavities have many diameters. The same micropores are connected. These tiny pores have uniform diameters, which can adsorb molecules smaller than the pore diameter into the inside of the pores, while repelling molecules larger than the pores, so that molecules with different shapes and diameters can be excluded. Molecules with different degrees of polarity, molecules with different boiling points, and molecules with different degrees of saturation are separated, that is, they have the function of “sieving” molecules, so they are called molecular sieves. At present, molecular sieves are widely used in metallurgy, chemical, electronics, petrochemical, natural gas and other industries.

Molecular sieve is a kind of aluminosilicate crystal. Because the pore size of zeolite molecular sieve is uniform, only when the molecular dynamics diameter is smaller than that of zeolite molecular sieve can it easily enter the cavity and be adsorbed. Therefore, zeolite molecular sieve is like a sieve for gas and liquid molecules. According to the size of the molecule to determine whether to be adsorbed. Because the zeolite molecular sieve has strong polarity in the crystalline cavity, it can interact with the molecules containing polar groups on the surface of the zeolite molecular sieve, or by inducing the polarization of the polarizable molecules to produce strong adsorption. This kind of polar or easily polarized molecule is easily adsorbed by polar zeolite molecular sieve, which reflects another adsorption selectivity of zeolite molecular sieve.

There are two main methods of molecular sieve regeneration: heating and high temperature regeneration and vacuum regeneration. Since the adsorption does not cause chemical changes, as long as you try to drive off the molecules that are concentrated on the surface, the zeolite molecular sieve has adsorption capacity again. This process is the reverse process of adsorption, called activation, or desorption or regeneration. Molecular sieve activation refers to the process in which adsorbates such as moisture adsorbed by the molecular sieve are driven out of the molecular sieve through high-temperature heating or vacuuming, so that the molecular sieve can restore the adsorption capacity.

With over 20 years of experience, Jalon has established itself as one of the most trusted molecular sieves suppliers in China and worldwide. Our expertise and commitment to innovation set us apart from other molecular sieve manufacturers, ensuring that our customers receive the highest quality products and services.

Yes, at Jalon, we pride ourselves on being a customer-centric molecular sieve factory. Our expert team works closely with clients to develop customized molecular sieve solutions that are tailored to their specific requirements. Whether you need a unique pore size or a special formulation, we have the knowledge and resources to deliver a product that meets your exact specifications.

Jalon boasts one of the largest production capacities among molecular sieve manufacturers, with state-of-the-art facilities and automated production lines. As a leading molecular sieve supplier, we are well-equipped to handle large-scale orders without compromising on quality or delivery time. Our streamlined processes and advanced infrastructure ensure that we can meet the demands of even the most challenging projects.