We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

JALON will be exhibiting at EXPOMIN 2025, one of Latin America’s largest and most influential mining trade shows, in Santiago, Chile from April 22 to 25, 2025. As a leading molecular sieve manufacturer, JALON will present its cutting-edge molecular sieve solution for oxygen enrichment, which helps improve efficiency and sustainability in the metal smelting industry.

Company Name: Luoyang Jalon Micro-Nano New Materials Co., Ltd

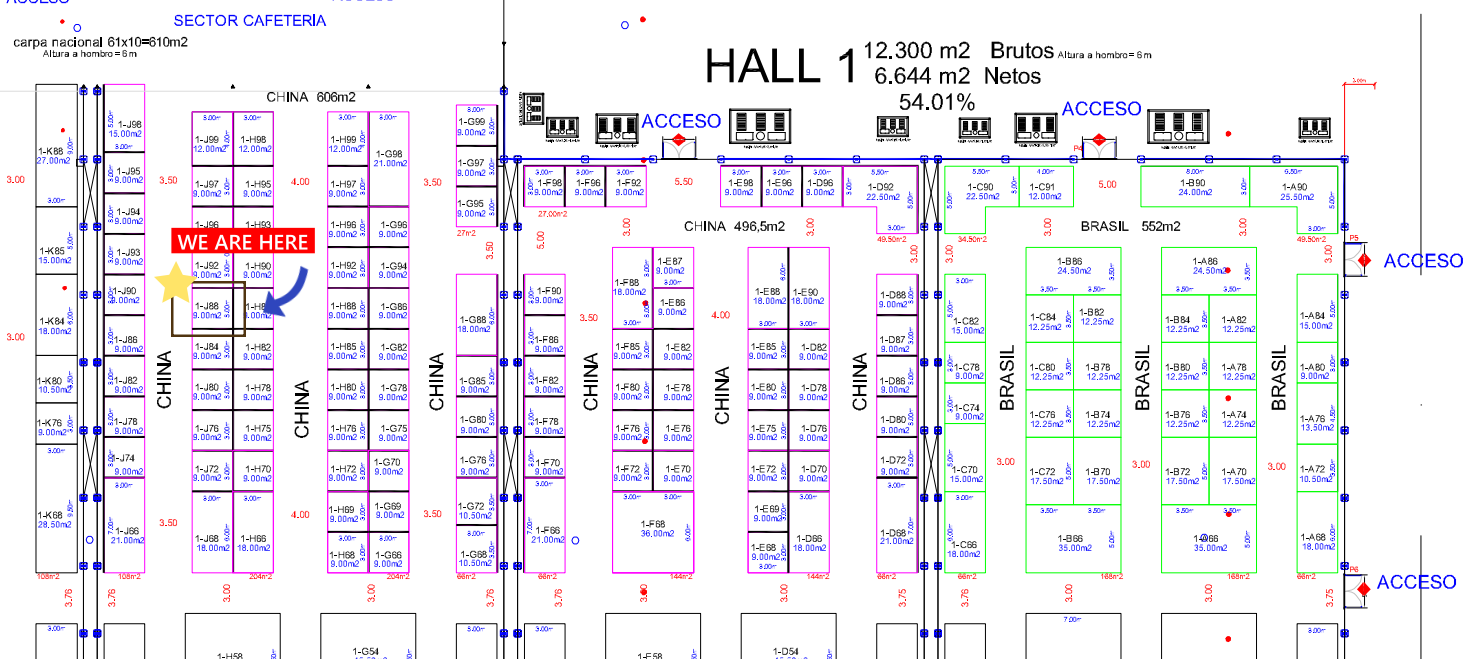

Booth No. : Hall 1 – Booth J88

Contact Person 1: Mr. Jack Zhang

Tel/Whatsapp/Wechat: +86 13700790205

Contact Person 2: Mr. Joao Costa

Tel/Whatsapp: +55-11-93211-4565

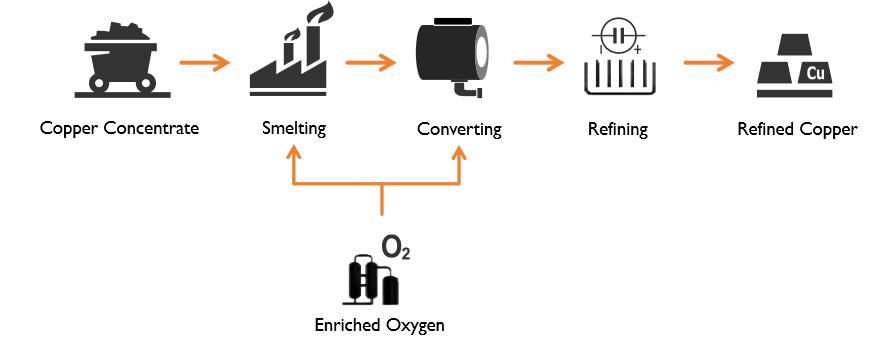

In the smelting of non-ferrous metals such as copper and nickel, oxygen plays a vital role throughout the entire metallurgical process. It boosts furnace temperatures, reduces fuel consumption, and plays a key role in refining to enhance metal purity. Using copper smelting as an example, oxygen is particularly critical in the following two stages:

During the initial smelting process—typically performed in high-temperature furnaces such as flash or bath smelters—copper concentrate is heated to over 1,200°C. This breaks down sulfide ores and produces a semi-refined product known as matte, which contains around 40%-70 % copper. By enriching combustion air with oxygen, the process generates enough internal heat, which significantly reduces the need for supplemental fuel and improves energy efficiency.

Following the smelting stage, the matte undergoes further processing in converters, where oxygen-enriched air is injected to oxidize and remove remaining iron sulfide (FeS) and sulfur. This step increases the copper purity to 97% or higher. In this phase, oxygen is not only a reactive agent but also enhances the efficiency of the overall reaction, leading to improved recovery rates. A reliable and efficient oxygen supply is therefore essential for achieving high-purity copper production.

Jalon Successfully Delivers Adsorbents Replacement Project for Glencore On-site Oxygen Generators

JALON’s flagship molecular sieves JLOX series, are the core material used in Pressure Swing Adsorption (PSA) and Vacuum PSA (VPSA) oxygen generation systems. These systems selectively adsorb nitrogen from the air, enabling oxygen enrichment on-site in a more cost-effective and energy-efficient manner compared to traditional cryogenic processes.

| JLOX-103 Series | JLOX-200 Series | JLOX-500 Series |

| Lithium-Base | Calcium-Base | Sodium-Base |

| VPSA | VPSA | PSA |

We cordially invite mining, metallurgy, and gas separation professionals from around the world to visit our booth. Let’s explore the future of energy-efficient oxygen supply together!