The family health oxygen generator uses air to produce oxygen, the desiccant can absorb water, the double-layer glass performs the heat insulation function, and the coating can prevent foaming. These familiar scenes in life are inseparable from a special material-molecular sieve.

What is a molecular sieve? It has a function to sieve the molecular, there are many pores with uniform pore size and neatly arranged holes to separate the molecular from size and scale. How big is the molecular? It is extremely small, about 1/10 of nano. In the area of adsorbent,how the molecular sieve makes air through it, makes 3.5A O2 through it,and makes molecular 3.6A N2 and 4A H2O adsorb in the molecular sieve. These fine pores and cavities formed by clever physical and chemical changes are exactly the difficulty of molecular sieve technology.

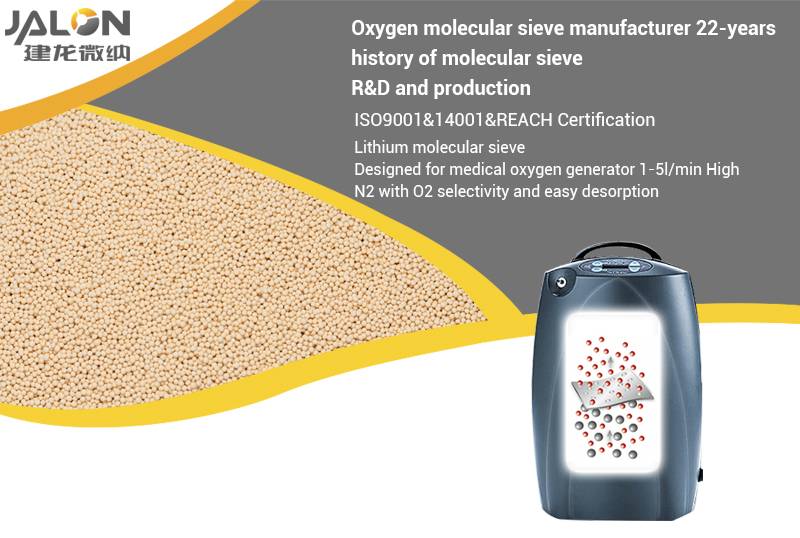

Jalon Micro-nano company is the first one of Henan Science and Technology Innovation Board that landed on the Science and Technology Innovation Board market—-one of the leaders in the domestic adsorption molecular sieve industry. Through the combination of independent R&D and cooperative R&D, the company actively promotes the implementation of industrialization, forming a molecular sieve whole industry chain layout based on molecular sieve raw powder, molecular sieve activated powder, and formed molecular sieve. In 2018, there were only nine molecular sieve adsorbent manufacturers with a capacity of over 10,000 tons in the world, and their production capacity accounted for 64.75% of the global production capacity. Three of them were Chinese companies. Jalon Micro-nano company has a leading position in the domestic molecular sieve adsorbent market

Looking back at the history of the development of molecular sieves in China, domestic research on molecular sieves began in the 1960s. At this time, in the United States, molecular sieves had basically achieved industrialization and were at the forefront of the world. With the advancement of China’s reform and opening up, foreign capital has entered China, bringing new development opportunities to China. In 1988, Shanghai Global Molecular Sieve Co., Ltd. was established. This is a joint venture between UOP, a leading international molecular sieve company, and Shanghai Molecular Sieve Factory. UOP accounts for 70% of the shares. The factory’s actual production capacity has been increased from 10 tons at the initial stage of the establishment of the Shanghai Molecular Sieve Factory to 10,000 tons. level. Since then, advanced technologies of A and X molecular sieves have entered China, which has greatly promoted the development of China’s molecular sieve industry.

Most of the domestic molecular sieve plants were born in the 1990s. Jalon Micro-nano company was established in 1998, focusing on the molecular sieve adsorption field. In recent years, the company has had obvious advantages in the fields of hydrogen production, oxygen production, and adsorption drying.

Jalon Chairman Li Jianbo said that there are 148 kinds of molecular sieves in the world, and more than 20 kinds are used in industry. We have Type A and Type X mainly used in oxygen production, hydrogen production, and deep dehydration. In 2018, the domestic market accounted for 11.24% and 43.17%, totaling 16.92 %.

Li Jianbo said that in the field of oxygen production, as the steel, coal chemical, non-ferrous metal smelting, glass and other industries have improved fuel combustion efficiency and people’s quality of life requirements, industrial oxygen production and medical and health care oxygen absorption have become more and more widely used. At present, the upgraded molecular sieve for cryogenic oxygen plant and pressure swing adsorption oxygen generators need to use molecular sieves and regularly replace them. Generally, the replacement cycle of molecular sieve for cryogenic air separation oxygen generation equipment is 3-5 years. The PSA oxygen generator replacement period of 8-10 years, which means that molecular sieve has become a rigid demand product in the oxygen production industry, and there is a vast stock replacement and new market demand.

JLOX-100 oxygen series which is a lithium molecular sieve: JLOX-100, JLOX-103 is bigger beads suitable for VPSA oxygen genreator > 300 Nm3/hour machine. JLOX-101 is suitable for small medical oxygen generator;JLOX-500 series that is a non-lithium molecular sieve: JLOX-500 is bigger beads for PSA oxygen generator <300 Nm3/hour. JLOX-501 is suitable for small medical oxygen generator;LOX-100 is higher performance than JLOX-500 and more expensive than JLOX-500. Both of the molecular sieves for oxygen generator with purity of 93±3%

Molecular sieve oxygen generators generally use pressure adsorption and atmospheric desorption (PSA). The two adsorption towers alternately carry out the same cycle process, thereby continuously supplying oxygen.

After the raw material air is pressurized by the compressor, it passes through the air pretreatment device to remove oil, dust, and other solid impurities and water. After the air is cooled to normal temperature, the treated compressed air enters the adsorption tower equipped with molecular sieve through the intake valve. Nitrogen and carbon dioxide in the air are adsorbed, and the output gas is high-purity oxygen. When the adsorption tower reaches a certain degree of saturation, the inlet valve is closed, the flushing valve is opened, and the adsorption tower enters the flushing stage. After that, the flush valve is closed and the desorption valve is opened to enter the desorption regeneration stage. This completes a cycle. This process is circulated through two adsorption towers to achieve continuous oxygen supply.

Advanced principle: through molecular sieve, pressure swing adsorption technology (PSA) is used to separate oxygen and nitrogen in the air to obtain high-purity oxygen that meets medical oxygen standards.Low cost of oxygen production: using air as raw material, no additives, no residue and pollution emissions, low power consumption.Easy to use: plug in to produce oxygen, simple operation, stable oxygen concentration, adjustable oxygen flow, ready-to-use, continuous oxygen supply for 24 hours.Safe and reliable: the whole set of the gas circuits is controlled by a low-pressure system, with stable performance and low noise.

1. When the oxygen generator is turned on, do not place the flowmeter float on the zero position;

2. It is forbidden to start the machine without installing the filter and filter;

3. When the oxygen generator is working, try to place it in a clean indoor place, and the distance from the wall or other surrounding objects is not less than 20 cm;

4. The oxygen generator should be placed steadily, otherwise it will increase the noise of the oxygen generator;

5. When using the oxygen generator, avoid open flames to avoid fire;

6. The water level in the humidification bottle should not be too high (the water level should be half of the bottle body), otherwise the water in the bottle will easily escape or enter the oxygen suction tube;

7. When the patient uses the oxygen generator, please prepare other emergency measures in case of power failure and other failures that affect the patient’s oxygen use;

8. During transportation and storage, it is strictly forbidden to place it horizontally, upside down, damp or direct sunlight;

9. When the oxygen generator is not used for a long time, please cut off the power, pour off the water in the humidification bottle, wipe the surface of the oxygen generator clean, cover it with a plastic cover, and store it in a dry place without sunlight;

10. Remember to cut off the power when cleaning oxygen generators, filters, etc. or replacing insurance;

11. When filling the oxygen bag with the oxygen generator, pay special attention. After the oxygen bag is filled, you must first unplug the oxygen bag intubation, and then turn off the oxygen generator switch, otherwise the water will be sucked back into the oxygen generator and cause malfunction.

P.S.: You are welcome to follow our LinkedIn account. We will regularly share more knowledge and topics about Molecular Sieves for everyone to learn and discuss together.