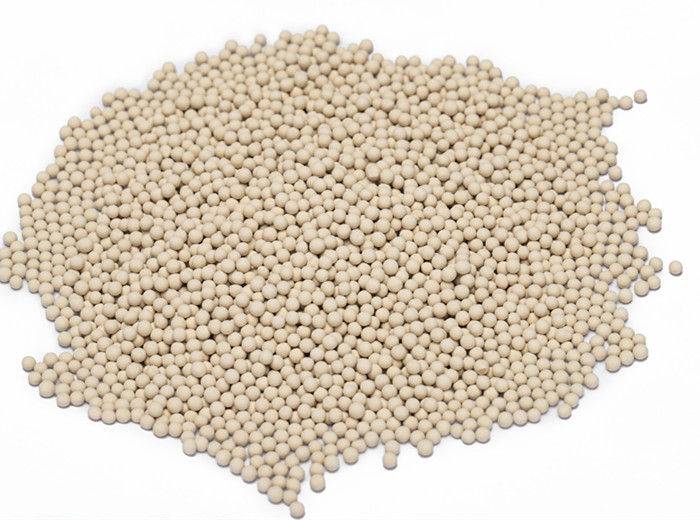

Molecular Sieve

- 3A Molecular Sieve

- 4A Molecular Sieve

- 5A Molecular Sieve

- 13X Molecular Sieve

- Molecular Sieve JLCOS

- Hydrogen Sieve JLPH5

- Molecular Sieve JLVC-1

- Molecular Sieve NSP-4

- Molecular Sieve JLRD-7

- Lithium molecular sieve JLOX-100

- Air Separation JLOX-300

- Oxygen Molecular Sieve

- Cryogenic Air Separation JLPM

- CaX molecular sieve

- JLHA-100 Ag-Zeolite Hydrogen Getter