We value your privacy

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

No cookies to display.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

No cookies to display.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

No cookies to display.

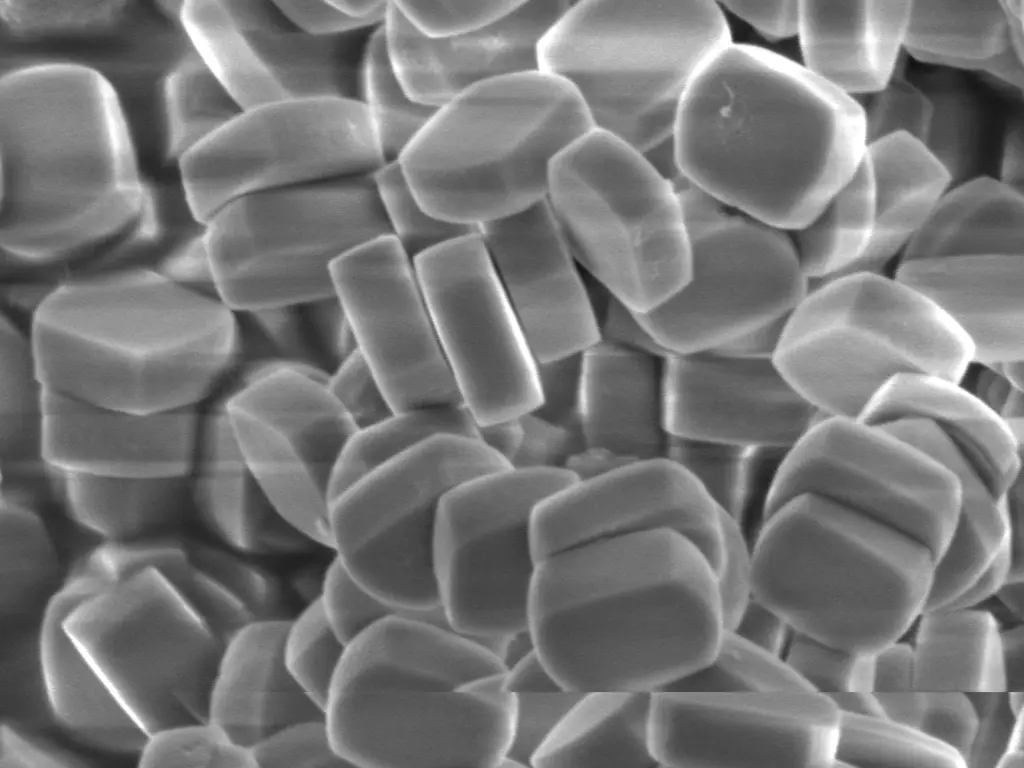

ZSM-5 is a synthetic zeolite, with the full form Zeolite Socony Mobil–5 (framework type MFI). It belongs to the pentasil family of aluminosilicate zeolites and is widely utilized as a heterogeneous catalyst in the petroleum industry, particularly for hydrocarbon isomerization reactions.

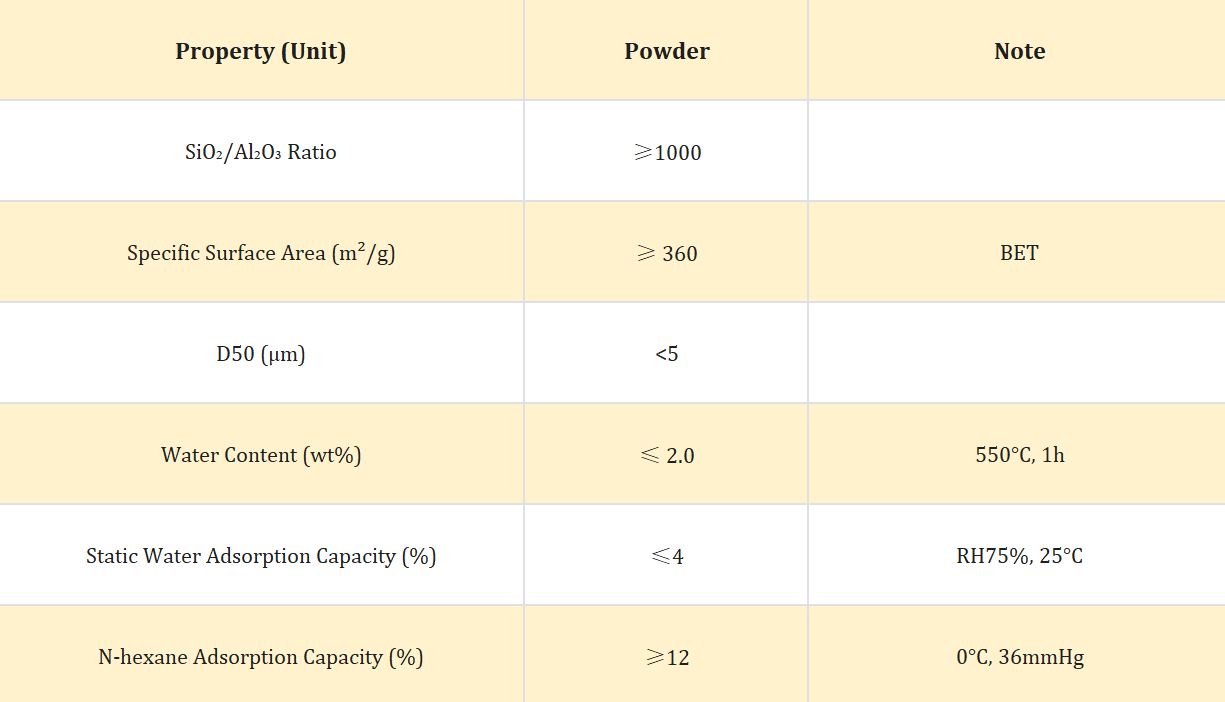

With its high silica-to-alumina ratio, ZSM-5 is valued both as a catalyst and a hydrophobic adsorbent. Its unique pore structure, featuring medium-sized pores of approximately 0.55 nm, enables shape-selective catalysis, making it highly effective in refining and hydrocarbon transformation processes.

ZSM-5 also serves as a versatile support material in catalysis, finding broad application in automobile catalysts, VOC (Volatile Organic Compound) traps, as well as in oil refining and petrochemical industries. Its excellent thermal and hydrothermal stability, along with superior acid distribution and resistance to coking, extend its use to environmental protection, photocatalysis, and biomass energy applications.

ZSM-5’s robust framework of eight five-membered rings and an orthorhombic crystal system maintains integrity up to 1100°C, ensuring reliable catalytic activity. This resilience not only prolongs catalyst life but also reduces operational costs by enhancing efficiency under extreme industrial conditions, providing a competitive advantage.

With a silica-to-alumina ratio ranging from 20 to infinity, ZSM-5 can be fine-tuned for optimal acidity and hydrophobicity. This flexibility allows it to adapt to specific catalytic needs, boosting efficiency and productivity in processes from fuel refinement to advanced chemical synthesis, increasing return on investment.

ZSM-5’s ten-membered ring channels offer pore sizes of 0.51×0.55 nm and 0.53×0.56 nm, ensuring shape-selective catalysis. This precision maximizes reactant conversion and product yield, reducing waste and improving product quality in petrochemical processes, leading to higher profit margins.

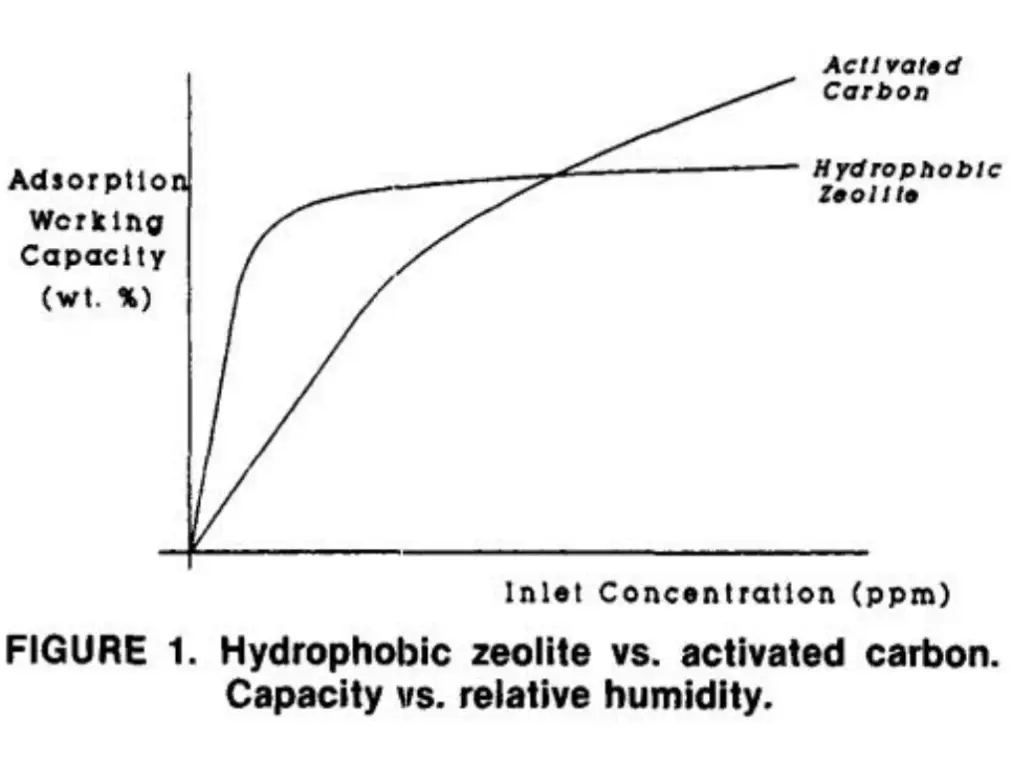

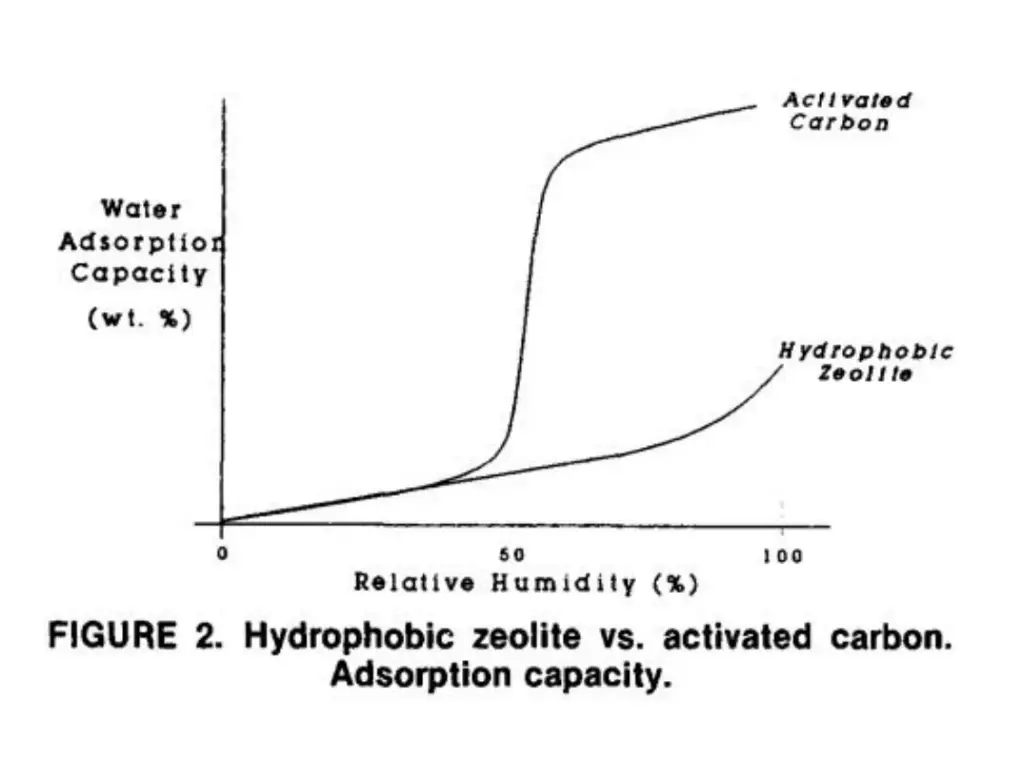

High silica content gives ZSM-5 superior hydrophobicity, outmatching other zeolites in humid VOC separation. This efficiency in adsorbing nonpolar molecules minimizes water interference, enhancing process reliability and reducing costs associated with VOC recovery and emissions control.

The NaAlSi(96-n)O192·16H2O framework of ZSM-5 resists all acids except HF, ensuring durability in acid-rich environments. This resistance allows for longer catalyst life and less frequent replacements, decreasing maintenance expenses and operational disruptions.

Interconnected elliptical and sinusoidal channels in ZSM-5 prevent coke formation, maintaining active catalytic sites. This enhances process stability and reduces maintenance needs, optimizing productivity and minimizing downtime in hydrocarbon processing for cost-effective operations.

Our comprehensive research efforts in ZSM-5 technology highlight our expertise and innovation capabilities. With high crystallinity, controlled morphology, and versatile synthesis abilities across a full range of silica-to-alumina ratios, we tailor particle sizes to meet specific client demands. We primarily supply powders to honeycomb and rotor manufacturers, and also produce 1/8-inch extrudate zeolites. These strengths ensure superior product performance, positioning us as a leader in the zeolite industry.

.webp)

Introduction

Introduction

Our advanced hydrophobic zeolite adsorbent offers exceptional VOCs adsorption capacity with low water uptake, making it ideal for selectively capturing VOCs in moisture-rich environments. With a stable, recyclable structure and extended lifespan, it serves as a superior alternative to traditional activated carbon and carbon fibers, defining a new generation of VOCs adsorption solutions.

ZSM-5 plays a crucial role in the petroleum and petrochemical industries due to its exceptional catalytic properties and versatility. Its ability to enhance fuel production efficiency and product quality makes it indispensable for industrial applications. We offer a wide range of ZSM-5 products tailored to meet diverse customer needs, ensuring optimal performance and competitiveness in various refining and chemical processes.