Introduction

For the modern world, the supply of oxygen to industries is necessary and it must be reliable and efficient. Pure oxygen demand in health centers is increasing as well as in wastewater treatment plants. That’s why PSA oxygen generators are employed for such purpose. These new devices apply state-of-the-art technology to take out oxygen from natural air thus providing an economical and environmentally friendly way of producing this gas.

What is a PSA Oxygen Generator?

A PSA oxygen generator is an advanced device that utilizes the principle of pressure swing adsorption to produce oxygen at high purity from ambient air. Here, compressed air is passed through a molecular sieve bed in which nitrogen molecules are selectively adsorbed and oxygen molecules allowed to pass through. This allows the PSA system to separate oxygen from the mixture of gasses in the air by cyclically exposing the molecular sieves to high and low pressures so as to maintain a constant flow of gas rich in oxygen.

PSA generators for oxygen have both simplicity and efficiency together. Unlike older ways of producing cryogenic liquids, which involve energy intensive processes like liquefaction and distillation, PSA technology works under normal temperature and pressure conditions. As such, less power is consumed and expensive complex equipment becomes unnecessary. The other advantage with these generators is their adaptability as regards flow rate or even level of purity for different applications.

Applications of PSA Oxygen Generators

Various sectors cannot do without PSA oxygen generators because of their flexibility. It is in the medical field where they act as a reliable source of medical grade oxygen for hospitals, clinics and home health care situations. The systems ensure that there is steady and uninterrupted supply of oxygen which is essential in taking care of patients as well as emergencies. Moreover, PSA oxygen generators are heavily used in industrial applications. This ranges from water treatment and aquaculture to glass making and metal shaping all which require pure oxygen. Hence, PSA technology solves the challenge of transporting costly and logistically demanding liquid oxygen by providing an on-site means for producing it.

Additionally, natural gas industry highly depends on PSA oxygen generators. Molecular sieves are usually employed to get rid of moisture and impurities from the gas stream during natural gas dehydration or drying process. When integrated into these processes, PSA oxygen generators can enable efficient gas purification while generating oxygen for other downstream applications. Oxygen generation and gas purification using molecular sieves has been changed by this unity between them and PSA technology so that a sustainable cost effective solution for industries globally has been availed to us.

The PSA Oxygen Generator Working Principle

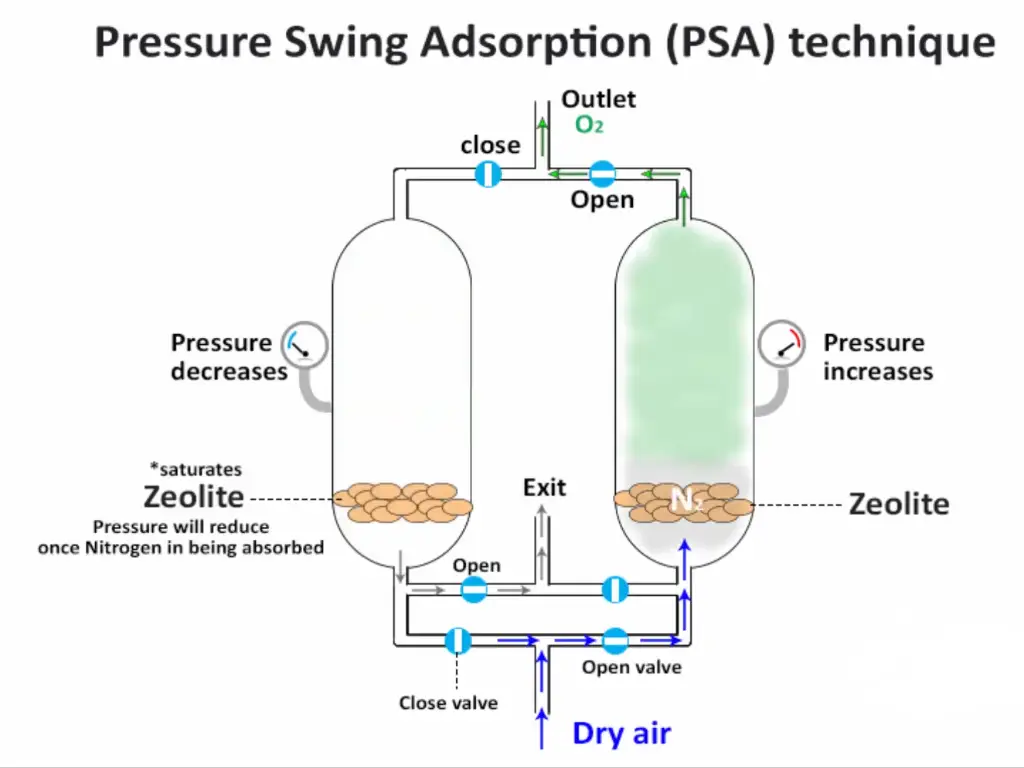

At the core of a PSA oxygen generator, you will find the pressure swing adsorption process. This advanced technology exploits the discriminatory adsorption power of zeolite molecular sieves to isolate oxygen gas from air. The process is characterized by two main stages: adsorption and desorption. In the course of adsorption, compressed air is fed into an adsorber containing the molecular sieve. As such, nitrogen gas molecules preferentially absorb into the pore system of the zeolite rather than pass through them, such that as much as possible, only oxygen reaches out while others are left behind in the sieve unabsorbed, hence enriching the resultant stream.

As soon as the saturation point is reached by the molecular sieve, the system shifts to the desorption cycle. In this regard, when high pressure goes down in an absorber container, the absorbed nitrogen gas is released, thereby being vented outside. That revives it back, ready for another cycle of absorption. By repeating these two steps without interruption, high purity oxygen gas in large quantities can be produced continuously as required by customers in a psa oxygen plant. The efficiency and efficacy of the PSA process depends largely on the characteristics and performance of the molecular sieve employed therein.

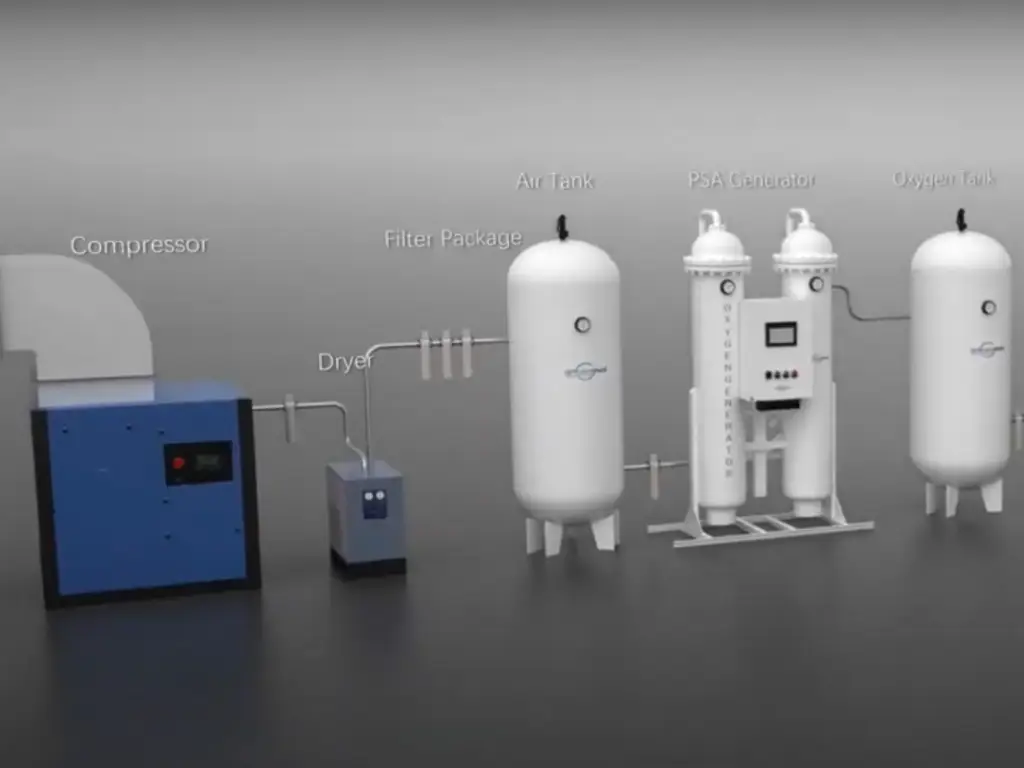

Key Components of a PSA Oxygen Generator

In an attempt to understand how a PSA oxygen generator works, it is important that we examine some of its most significant constituents. All these parts operate together in order to facilitate efficient production and delivery of oxygen.

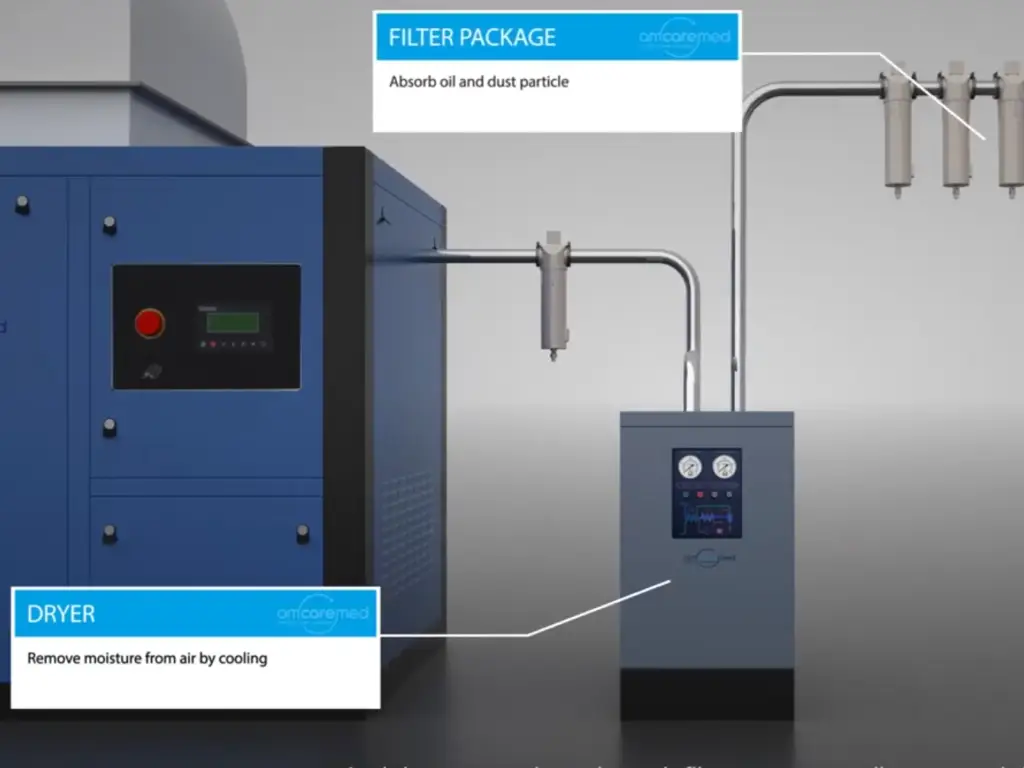

Air compressors and air filters

Firstly, the journey towards oxygen begins with the compression of surrounding air. So as to at least adsorption level a top notch air compressor are used to pressurize air. Nevertheless, prior to the entry of compressed air into adsorber vessels, it must go through various types of filters. Dust particles, oil droplets and moisture among other impurities are filtered out by these filters hence ensuring preservation and purity of molecular sieves. The efficacy and life span molecular sieves hinge on the cleanliness degree of incoming air thus making filtration processes vital during PSA process.

Molecular Sieves

Molecular sieves are the heart of a PSA oxygen generator. These artificial zeolitic substances have a special internal structure, which makes them capable of adsorbing selectively nitrogen atoms while passing through oxygen ones. The molecular sieve most widely employed in the generation of oxygen is zeolite 13X with pore size approximately equal to ten angstroms. The purity and yield of generated oxygen are directly related to adsorption capacity and selectivity of molecular sieve.

Oxygen Storage Tank

The PSA process generates and purifies oxygen which is then put into a separate storage tank. The tank serves as an oxygen buffer that keeps the supply steady and consistent even during demand peak periods. When designing the size of this storage tank, one has to consider specific applications together with required oxygen flow rates. Therefore, proper sizing and maintenance of the O2 storage tank are absolutely essential for uninterrupted operation of PSA oxygen generators. So regular inspections and safety checks are done on the storage system to ensure it performs well without any fault in it.

| Component | Function | Example |

| Air Compressors | Compress surrounding air to required adsorption-level pressure | High-efficiency air compressors |

| Air Filters | Remove impurities such as dust, oil droplets, and moisture | Pre-filters, coalescing filters |

| Molecular Sieves | Selectively adsorb nitrogen molecules to separate oxygen | Zeolite 13X |

| Oxygen Storage Tank | Store and buffer the oxygen to ensure steady supply | Custom-sized tanks based on capacity requirements |

| Control Systems | Monitor and adjust flow rate and purity levels of oxygen | Real-time sensor and control units |

Selecting the Right Molecular Sieve for PSA Oxygen Generators

The performance of a PSA oxygen generator depends heavily on the choice of appropriate molecular sieve. Different molecular sieves have different adsorption attributes that affect the oxygen purity, recovery rate and overall efficiency of the system. There are several factors to take into account when selecting a molecular sieve for oxygen generation including nitrogen adsorption selectivity, adsorption capacity, pore size and distribution.

Zeolite 13X is widely acknowledged as industry standard in PSA oxygen generators, due to its special pore structure and adsorption properties. Meanwhile research and development concentrates on new generations of novel molecular sieves with improved performance features. These advanced materials are aimed at enhancing oxygen purity while increasing absorption capability and reducing consumption rates involved in PSA systems. The right molecular sieve is therefore an essential part of optimizing the performance and efficiency of a PSA Oxygen Generator.

Jalon has developed JLOX series which is one example of advanced molecular sieves for PSA Oxygen production. Among these is a high-efficiency X type Molecular Sieve known as JLOX-500 meant specifically for industrial oxygen production by means of pressure swing absorption technique or medical center’s requirement for oxygen supply system; it has an extremely high nitrogen adsorption capacity coupled with excellent separation coefficient between N2 to O2. Moreover, JLOX-501 is designed for portable medical oxygen concentrators with flow rates ranging from 1-5 L/min achieving up to 93%±3% oxygen purity level. These advancements represent the possibility that exists within the current technology regarding improved yields in addition to cost effectiveness associated with pressure swing absorption (PSA) generated O2.

The PSA Process: Adsorption Stage

After that, the adsorber vessel containing the molecular sieve receives compressed and filtered air in the course of the adsorption stage. As a remarkable phenomenon, there happens a molecular interaction between air and the sieve bed which leads to selective adsorption of nitrogen (N2). This molecular sieve is typically zeolite 13X with specific pore size and surface chemistry that attracts nitrogen molecules strongly due to its specific pore size and surface chemistry. Nitrogen molecules are attracted to the zeolite surface where they become trapped within its pores as the air mixture passes through it. In turn, this selectivity in adsorption is driven by higher quadrupole moment of nitrogen as compared to oxygen leading to stronger interactions between nitrogen and Zeolite framework.

When this occurs, oxygen-enriched gas stream remains after selective adsorption of nitrogen molecules by molecular sieves. Oxygen molecules being slightly smaller than nitrogen will pass through relatively unaffected from their path found in and through the bed or directly out into downstream regions. This process continues until at some point when all of them are filled up with N2 then we say that such an adsorber vessel is saturated with nitrogen. Consequently, this process is considered vital at the first stage prior to making any high purity oxygen using the PSA system and principles hence setting pace for production of high-quality oxygens. The overall function of system may be influenced largely by efficiency during absorption process together with molecular sieve selectivity.

The PSA Process: Desorption Stage

The PSA system switches to the desorption stage once the molecular sieve in the adsorber vessel gets saturated with nitrogen. The desorption process is important for regenerating the molecular sieve and preparing it for subsequent adsorption cycles. Pressure in the adsorber vessel drops rapidly during desorption. The sudden pressure drop disturbs equilibrium between nitrogen molecules that are adsorbed and zeolite surface. Consequently, molecules of nitrogen leave molecular sieve’s pores and vent out of a system. Purge gas will usually be employed to assist desorption, which typically generates oxygen and is used to sweep off the released nitrogen.

The process of desorption does not only remove adsorbed nitrogen but also brings back molecular sieve into its original condition so that it can be used again in another cycle. Duration and conditions of desorption stage have to be controlled well for complete regeneration of sieve material. If there is not enough desorption, this leads to gradual degradation in performance over several following cycles affecting purity of oxygen and production efficiency. Once this phase is accomplished, another cycle of adsorption will occur in a molecular sieve. Continuous cycling between absorption and desorption makes the PSA Oxygen Generator maintain a constant supply of high purity oxygen without any failure or interruption at all times.

Controlling Oxygen Purity and Flow

The ability to control the purity and flow rate of the oxygen produced is one of the most important benefits derived from PSA oxygen generators. This makes it possible for them to be adjusted so that they meet specific requirements for numerous applications. Oxygen purity on the other hand can be regulated by modifying parameters like pressure swing, as well as adjusting adsorption and desorption cycle times. Generally, higher oxygen purity results from adsorbing for longer periods or adsorbing at high pressures while lower overall oxygen yields may result in purer forms of oxygen. On a typical PSA system, an oxygen purity level between 90% and 95% is common depending on design specifics and operating conditions.

Flow rate into vessels containing adsorbers and cycling frequency among absorption and desorption are used to control airflow of generated O2. Increasing airflow rates and reducing times for recycling enhance O2 production performances. However, management must ensure that flow rates do not exceed molecular sieve adsorption capacities thereby guaranteeing optimal performance while preventing nitrogen breakthroughs before their time. Nitrogen exhibits a finite capacity for being absorbed when utilizing molecular sieves like zeolite13X in the manufacture of PSA oxygen generators. If air flows too fast or cycles turn around quickly; N2 may fail to get fully sucked up before nitrogen subsequently begins promoting early breakthroughs hence affecting the quality of produced O2. In advanced PSA oxygen generators, real-time operations adjustments are done through use of sophisticated control systems and sensors.The continuous monitoring of crucial variables including flow rate, oxygen purity by such systems allows automatic attainment under set targets. This feature ensures uniformity in quality and reduces manual labor by bringing down human intervention levels while controlling gas mixing properties

| Parameter | Typical Value Range | Impact on Oxygen Purity | Impact on Oxygen Production Efficiency |

| Adsorption Pressure | 4-6 bar | Higher pressure increases purity | Optimal pressure maximizes efficiency |

| Desorption Pressure | Near atmospheric pressure | Lower pressure aids in desorption | Efficient desorption enhances cycle time |

| Adsorption Time Duration | 30-120 seconds | Longer time increases purity | Balancing time optimizes throughput |

| Desorption Time Duration | 30-60 seconds | Adequate time needed for complete regeneration | Shorter duration speeds up cycle |

| Inlet Air Temperature | Ambient (15-25°C) | Stable temperature ensures consistent performance | Variations can affect sieve efficiency |

Benefits of PSA Oxygen Generators

Thence, PSA oxygen generators have a lot of merits over normal oxygen generating methods like cryogenic liquid oxygen or compressed oxygen cylinders. Firstly, PSA oxygen generators offer an economical approach to generate on site oxygen hence eliminating regular deliveries of the gas and transportation and storage expenses. Secondly, if well taken care of, PSA systems can work ceaselessly thus enabling continual supply of oxygen without interruption. Especially when a steady flow rate has to be maintained like in medical institutions and industries that are utilizing it.

In addition, there are various scaling options available through the use of PSA Oxygen Generators. The generator can be designed for different levels of demand from small-scale medical applications to large-scale industrial processes. Besides, these generators are modular in nature hence making expansion easy so as to fit future requirements for increased volumes of Oxygen. Furthermore, the use of PSA technology is eco-friendly since it employs air sourced in ambient conditions thereby eliminating energy intensive cryogenic processes or transportations regarding compressed oxygen cylinders. Moreover, direct generation using this method reduces handling and storage incidents related to high pressure cylinders for gaseous O2 thereby improving safety and ease.

Maintaining PSA Oxygen Generators

It is a must that regular maintenance be done to ensure optimal performance and lifespan of the PSA oxygen generator. Proper taking care of it will not only guarantee constant supply of high-purity oxygen but also prevent downtime and expensive repairs. Regular replacement of air filters is among the most significant maintenance tasks. Air filters can eventually get clogged up by impurities, hence reducing the efficacy of air compression as well as purification processes.

In the maintenance of molecular sieves, monitoring them is essential as an additional aspect. As per a study by the American Chemical Society, molecular sieves are designed for extended lives under proper operational and maintenance conditions. The 13X molecular sieves used in PSA oxygen generators can, therefore, last from 30,000 to 40,000 hours or 3.4 to 4.5 years continuous operation on average. However, they may gradually stop absorbing efficiently due to moisture damage, contaminants or simply wear and tear through mechanical work. Periodic testing and evaluation of adsorbent performances will identify performance degradation or need for replacement.

To optimize the performance and lifespan of a PSA oxygen generator it is important that one adheres to the recommended service intervals and procedures as provided by the manufacturer’s manual. Molecular sieves usually have a lifespan ranging from every three to five years; whereas air filters should be inspected regularly with changing after six to twelve months time periods depending on operating conditions and quality of inlet air. Regular regeneration techniques like online heated regeneration or chemical washing can prolong their duration use. Nevertheless should there be a significant decrease in oxygen purity or pressure drop across the adsorber vessels it may require molecular sieve replacement. To obtain correct guidance on maintenance schedules and processes consult product manuals for molecular sieve manufacturers, technical specifications or experienced PSA oxygen equipment suppliers.

Routine inspection and servicing of compressors, valves, and other mechanical equipment are equally critical for efficient running of a PSA oxygen generator. There is a need for an all-inclusive maintenance program with adequate staff training in order to increase the life span of the PSA Generator and guarantee its efficiency over time.

Elevate Your Industry Solutions with Jalon’s Advanced Molecular Sieves

To facilitate maximum efficiency, companies using PSA oxygen generators must partner with a trustworthy molecular sieve supplier. It is considered as one of the greatest enterprises in the research, production and technical support cases on adsorption type molecular sieves which it had all started in 1998 (Jalon). Our range of advanced products like Zeolite 13X and other types of special molecular sieves is aimed at improving the performance of PSA systems. Opting for Jalon means that you will be supplied with new ideas and have a chance to receive prompt help from our staff thus ensuring high-purity oxygen output by your oxygen generators on an ongoing basis. Be among many users who depend on this company for their psa oxygen generation needs, experiencing improved product quality as well as knowhow in technology.

Conclusion

The evolution of PSA oxygen generators has completely changed how we make and distribute oxygen in various industries. These machines employ the PSA process, which utilizes molecular sieves with selective adsorption properties to provide an economical, reliable and eco-friendly solution for onsite oxygen production. Mastering the operational principles of the PSA oxygen generators is vital in enhancing their productivity and ensuring a constant supply of high purity oxygen.

The efficiency and effectiveness of the PSA process depend heavily on adsorption, desorption phases as well as suitable choice of molecular sieve. As technology advances further improvements will be made in the design, efficiency that is shown by a PSU generator for O2. The focus behind ongoing research and development activities seeks to improve materials for molecular sieves, optimize process parameters, and integrate intelligent control techniques. For this reason, embracing PSA technology while understanding its working principles opens up opportunities for industries towards sustainable efficient operation with minimal environmental impact when producing high purity O2 demanded extensively today.