When you hear the word “water desiccant”, you automatically think of the three common types of desiccants that are silica gel, clay desiccant, and molecular sieve. But, there are a lot more types of desiccants that you may not know about and even if you do, you might not have a clear understanding of them.

Realizing the importance of different types of desiccants, we have given detailed information on water desiccant material types and their applications.

What is Water Desiccant?

Water desiccant is a sorbent which means that it has the ability to attract and trap water molecules. Consumers are generally familiar with the water-absorbing packets of desiccants that come packed with the items that they purchased to prevent rust or mold due to moisture while shipping.

Water desiccants are specially used for imported items that spend a long time between dispatch and arrival. In industrial settings, they are used to dry the air in the operational systems that are deposited in the form of moisture.

Types of Water Desiccant

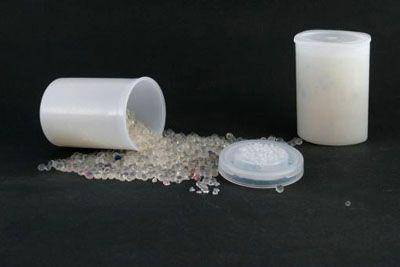

1. Montmorillonite Clay

Montmorillonite clay is a moisture absorbent material that occurs naturally and is created using controlled drying of magnesium and aluminum components. This desiccant can be successfully regenerated to be used repeatedly at low temperatures. However, this regenerating property causes the desiccant to give up the moisture trapped into the atmosphere easily if the temperature rises.

Some of the benefits of montmorillonite clay are:

- It is a naturally-occurring mineral that does not need much work to become a desiccant

- It is an economical desiccant

- The adsorption capacity of montmorillonite clay is considerable even when the levels of humidity are low

- It is minimally processed and is pure in nature

- It remains dry and free-flowing even after absorbing a lot of moisture

Application of montmorillonite clay:

Montmorillonite Clay desiccant can be used as a moisture absorbent to preserve items by preventing damaging effects caused by moisture.

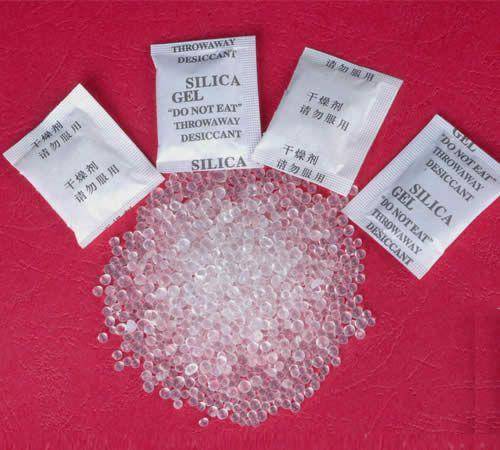

2. Silica Gel

Silica gel is a naturally occurring mineral that is cleaned and purified into beaded form to be used as a desiccant. The average pore size of silica gel is 24 angstroms which makes it easy to trap water molecules in its pores. The demoisturizer packetsof silica gel pull the moisture in up to 220°F and as the temperature goes above 100°F, the silica gel will slow down in picking up the moisture.

Silica gel performs at its best when the room temperature is 70°F to 90°F and the humidity in the room is high. It can drop the humidity level in a room up to 40% RH.

Just like clay, silica gel has a wide range of pore sizes which enables it to adsorb compounds other than water as well such as ammonia, aromatics, olefins, diolefins, and paraffin. Because silica gel can adsorb multiple components, you can expect the more strong compounds to displace the ones that are weakly held.

Application of Silica Gel

Silica gel is widely used in the United States in the food and pharmaceutical industries because silica gel humidity absorber packets have only been approved by the FDA for the products of these industries.

3. Indicating Silica Gel

Indicating silica gel is a type of silica gel that has been purified with a concentration of cobalt chloride which is blue in color. This helps the silica gel to turn from blue to pink when it comes in contact with moisture. When this desiccant typepasses through 8% moisture levels, its color will change, indicating that it is time to replace the silica gel packets.

Indicating silica gel helps in determining whether the desiccant needs to be recharged or replaced. It allows a rapid detection test by changing color because it absorbs moisture from the substances and eventually saturates to its peak point.

Some of the benefits of using indicating silica gel beads are:

- Its property of changing colors lets the user know when it is time to replace a package

- It remains dry and free-flowing when it comes in contact with moisture

- The adsorption capacity of indicating silica gel is relatively small than other desiccants at a low humidity level, but it increases when the humidity rises

- The process of adsorption is reversible by using the regeneration method

Application of Indicating Silica Gel:

The most common use of indicating silica gel is for inspecting moisture-sensitive products to get a quick visual of how well the product is doing. Indicating silica gel contains cobalt chloride, which is why it should not be used in food or pharmaceutical industries.

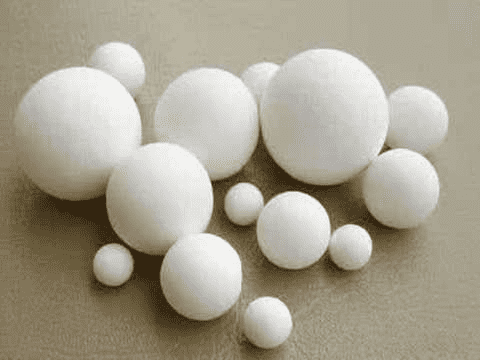

4. Molecular Sieve

Molecular sieves for water removalare the best desiccants based on their characteristics. They have the ability to absorb moisture even at high temperatures. They are synthetic crystalline aluminosilicates that have a strong affinity for very small-sized molecules. The significant characteristic of molecular sieves as compared to other desiccants is their uniform pores.

Some of the benefits of molecular sieve water desiccant:

- It is one of the most aggressive desiccant options

- The adsorption capacity of molecular sieve is relatively high as compared to other desiccants at a low humidity level and it remains constant even when the humidity increases relatively

- It is available in a wide array of packaging configurations

Application of Molecular sieves:

A molecular sieve for moisture removalis used as a drying agent and a separator of molecules based on their shapes and sizes. When there are two molecules of the same shape and size, the separation is done on the basis of the polarity of the molecules, the more polar molecule being the one adsorbed.

5. Calcium Oxide

Calcium oxide is one of the most popularly used desiccant typesthat is made by calcinating lime that has a moisture adsorptive capacity of 28.5% by weight. The feature that makes calcium oxide stand out is that it can absorb a lot of water vapor at a very low humidity than other desiccants. It works optimally when there is a low critical relative humidity and the water vapor present is of high concentration.

Application of Calcium Oxide

Calcium oxide is used primarily in packaging dehydrated foods as it helps remove water from a package very slowly, which means that it takes days to reach its maximum capacity.

6. Calcium Sulfate

Calcium sulfate is created using dehydration of gypsum in a controlled environment. This desiccant materialis available at a very low cost and has an equally low adsorptive capacity of 10% of its weight. It also possesses regeneration characteristics that limit its use in the real-life because the vapor gets released back into the atmosphere at low temperatures.

Application of Calcium Sulfate

Calcium sulfate is a general-purpose desiccant that is primarily used in laboratories because it is chemically stable, non-corrosive, no-disintegrating, non-toxic, and does not easily release the absorbed moisture even at high temperatures. It is used to experiment with the properties and applications of desiccants.

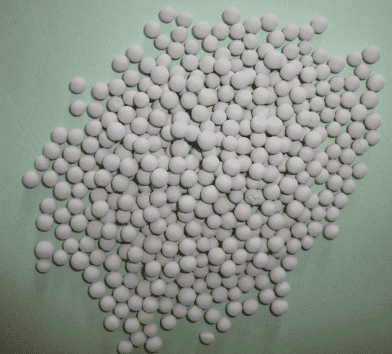

7. Activated Alumina

Activated alumina is one of the commonly used types of desiccantthat has very similar properties to silica gel. It provides a low moisture capacity at low temperatures a better capacity at higher temperatures. It should be noted that some of the activated alumina products have a specific function for different applications.

Activated alumina works on the principle of adsorption where the water in the air sticks to the alumina itself and gets trapped between the tiny passages of the alumina when the air passes through it. The air that passes out of the filter is completely dried out which can be regenerated by heating the alumina at 200 degrees Fahrenheit.

Application of Activated Alumina

Activated alumina is used for drying gases and as an adsorbent of toxic gases and odors. It has been extensively used for many years in military gas masks because of its property to absorb bad odors.

How to Choose the Right Water Desiccant?

Choosing the best desiccant material can prove to be inexpensive insurance that protects your packaged goods. It helps in improving the product quality, which results in reduced rejections by customers. When you are dealing with moisture problems in packaging, there is a wide range of variables that can make it difficult to come up with solutions. These variables are classified into:

- The one pertaining to the product, its packaging, and the environment

- The chemical and physical properties of the desiccants available in the market.

Here are some of the things that you should consider while selecting a desiccant.

Application of the Desiccant

It is important to determine what will be the application for which the moisture absorbent material will be used. For example, calcium chloride requires high levels of sustained moisture to perform optimally, which is why you do not need them inside packages. Packages have less humidity and it is not sustainable, which is why calcium chloride won’t help there. Silica beads packages are your answer in such situations.

Clay desiccants can’t absorb much moisture and will outperform calcium chloride in this condition. It will reduce the humidity inside the package faster and will reduce it to low levels.

The opposite condition is true in cases of shipping containers where there is extreme humidity which is sustained. In such conditions, calcium chloride will work optimally because it has the capacity to remove the required amount of moisture in the container.

Characteristics of the Desiccant

Another factor to consider while choosing different types of desiccant materialis the properties of the desiccants. You will have to consider what would be the result of the desiccant when it absorbs moisture. For example. Calcium chloride becomes a highly corrosive liquid when in contact with water which poses a risk of leakage. On the other hand, clay desiccants remain dry even at full vapor capacity.

Sustainability

It is important to check the sustainability of the moisture absorbent materials of thedesiccant that you choose because packaging materials comprise 95% of the desiccant’s makeup. The way a desiccant is packaged is a factor that cannot be overlooked. It must be able to prevent any kind of leakage from the time that it is packaged to the time it is delivered to the customers.

Conclusion

There are many different types of desiccant materials that are available in the market, but not all are suited for the same application. You can choose the right desiccant material for your application by determining the properties of the desiccant that are relevant to your application.