Introduction to Desiccants

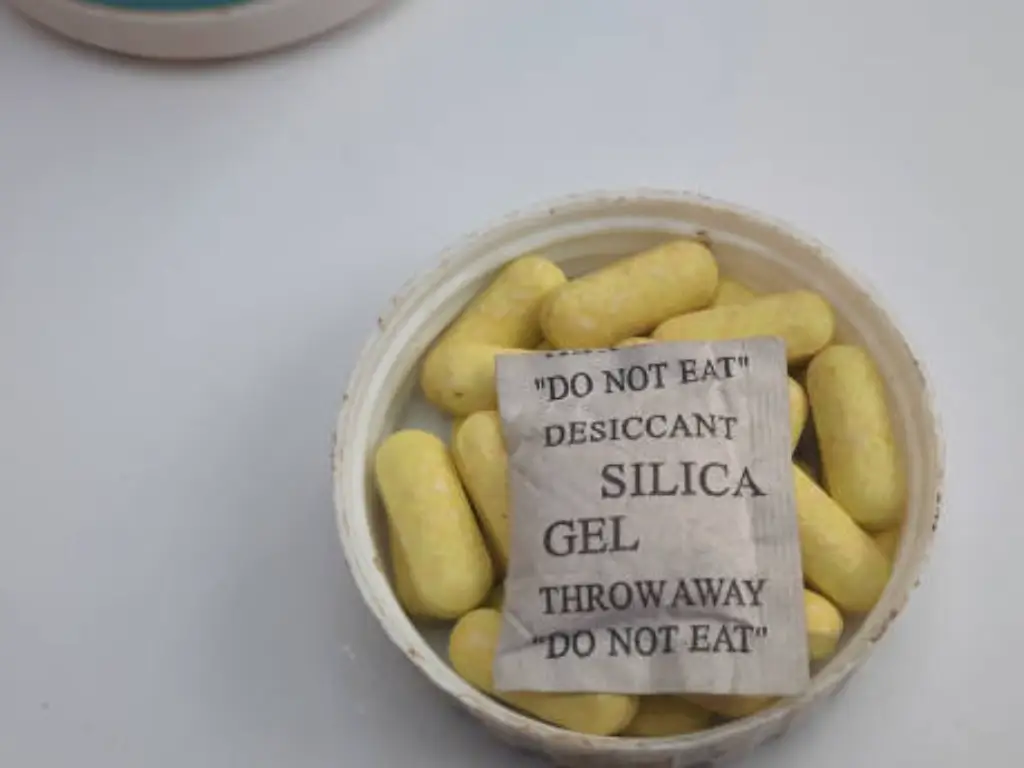

Have you ever excitedly opened that new pair of shoes or a new electronic gadget and saw those small packets with the writing ‘not for consumption’? Those packets contain desiccants, but what is a desiccant exactly? In a nutshell, a desiccant is a material that is capable of absorbing and retaining water molecules from the surrounding air. These materials assist in the reduction and the maintenance of low humidity levels that may cause damage to many products. Some of the widely used desiccants are silica gel, calcium chloride, and activated alumina. Desiccants, in turn, reduce the amount of moisture in the environment and keep the product in a dry state, thus increasing its durability and quality.

Importance of Desiccants in Various Industries

Moisture control has become critical in the modern society in many fields of endeavor. From drugs to electronics, to food packaging, the importance of desiccants cannot be overemphasized. In the pharmaceutical industry for example, moisture can affect the effectiveness of drugs and reduce their shelf life. Desiccants assist in keeping humidity away so that medications do not lose their efficacy and remain as potent as they should be. Water molecules can also interfere with the active ingredients by hydrolyzing them and thus decreasing the stability and effectiveness of the drug.

Hygroscopic Nature and Moisture Absorption

Desiccants are the main actors of hygroscopic substances that are able to absorb and retain moisture from the air. This property makes desiccants to always remain dry, which is very essential in avoiding any damage that may be caused by moisture. But how does these materials work in a way that they can absorb moisture? The answer is to be found in their chemical and physical characteristics. The majority of desiccants use adsorption, where water molecules stick to the surface of the desiccant material creating a thin layer. This mechanism is typical of silica gel and activated alumina, both of which can take up a large amount of water without experiencing any change in their structure.

Calcium chloride, on the other hand, uses absorption where water molecules are trapped within the structure of the desiccant material. This results in the formation of a liquid brine which is very useful especially in areas that are more moist. It is important to distinguish between adsorption and absorption so that the right material can be chosen for use in desiccation. For example, in situations where one needs to regulate the moisture content in small and enclosed areas and in a short span of time, then silica gel would be most appropriate. However, for large scale moisture control, calcium chloride might be a better solution to go for. This understanding is useful in selecting the right desiccant depending on the application of the particular process.

Types and Uses of Desiccants

Silica Gel

Silica gel is perhaps one of the most widely known and used desiccants in the modern world today. Made of silicon dioxide, this desiccant material is very porous in nature and can effectively adsorb water vapor. It can absorb moisture up to 40% of its weight and therefore is very useful for a number of purposes. This type of desiccant is commonly used in the packaging of electronics, leather products, drugs, food items, and even foods. The structure of silica gel is in the form of small granules that capture the water molecules in the small pores, hence preventing high humidity levels. Another benefit of silica gel is its ability to be reused; all that is required is to heat the desiccant product in order to restore its ability to absorb moisture. In addition to silica gel, there are different types of desiccants available, each designed to target specific molecules or conditions. When protecting metal items, much desiccant may be required to maintain a consistent state of dryness given the larger surface area that needs protection.

Silica gel is not only used to absorb moisture but has other uses too. For example, in electronics, the small packets containing silica gel are used to reduce the chance of moisture getting to the sensitive parts of the equipment and causing corrosion or short-circuiting. In the food industry, silica gel plays a role of maintaining the quality of perishable products by removing excess moisture in the packaging. This makes it an essential tool in different fields since it provides a reliable method of managing moisture. Due to its flexibility in use, and the fact that it can be recycled and reused, silica gel is a cost effective and efficient product in many industries.

Montmorillonite Clay

Montmorillonite clay is a natural desiccant which is obtained from a type of absorbent clay. Montmorillonite clay is a natural material, which makes it environmentally friendly as opposed to synthetic desiccants. This desiccant works on the principle of capillary condensation in which moisture is absorbed in the tiny pores of the clay particles. Montmorillonite clay is used in food and pharmaceutical packaging to reduce cost and act as a natural desiccant. Although it is a natural product, montmorillonite clay is very efficient, it is able to absorb a large amount of moisture to prevent high humidity in different environments. Furthermore, montmorillonite clay is also applied in the packaging of consumer products, including textiles, electronics, etc., to regulate the moisture. This is because it is natural and sustainable, and therefore it is suitable for industries that seek to achieve efficiency while at the same time maintaining ecological harmony.

Molecular Sieve

Molecular sieves are synthetic desiccants that are formed from crystalline aluminosilicates called zeolites. These desiccants are known to have a consistent pore size, which makes it possible to selectively adsorb molecules of a certain size. This precision makes the molecular sieves to be very effective in adsorbing certain molecules and excluding others. For instance, a molecular sieve might be made to selectively adsorb water molecules but not bulky hydrocarbon molecules. This selective adsorption ability is very useful in industries that need to maintain very low moisture content such as the petrochemical industries and air separation plants.

Molecular sieves are used in conditions that require strict regulation of moisture content. In the petrochemical industry, they have a significant function in the removal of water vapor in the gas to avoid formation of corrosive reactions in the pipelines and the equipment. In air separation plants, molecular sieves are used to dry the compressed air to prevent the formation of rust on the equipment and for the proper functioning of the equipment. Apart from industrial uses, molecular sieves are also applied in everyday products like double-glazed windows where they help to eliminate fogging between the panes, hence maintaining the transparency and the insulating capacity. Their effectiveness and flexibility make molecular sieves ideal for use in many sensitive processes.

Activated Alumina

Activated alumina is a highly porous desiccant material derived from aluminum oxide. It is mainly applied in processes that involve the removal of moisture from gases and liquids because of its large surface area and strong moisture elimination capacity. This desiccant operates through the adsorption process in which water molecules attach themselves to the surface of the alumina particles. Activated alumina is very efficient in high temperature conditions and can retain its moisture adsorption capability even in extreme conditions. This makes it a good candidate for dryer applications in many industrial processes.

The uses of activated alumina are not only limited to industries and various sectors only but also in other areas as well. It is widely used in air and gas drying applications where it assists in preserving the functionality and durability of the systems by eliminating moisture that may cause corrosion or other problems. Also, activated alumina is applied in water purification to filter out impurities including fluoride and arsenic. In the case of consumer products, this desiccant is used in dehumidifiers and other appliances that help regulate the moisture content in homes and offices. Because of its durability and high efficiency, activated alumina is a suitable product for various applications in moisture control.

Calcium Chloride

Calcium chloride is a very effective desiccant, which in simple terms means that it has a very high capability of absorbing water vapor from the atmosphere. This desiccant can hold more than its weight in water and turns the moisture into a liquid brine. Calcium chloride is used in applications that need high absorption capacity, for instance in large shipping containers to protect the goods during transportation. It is also used in residential moisture control products like dehumidifiers to keep basement, closets and other areas moist free.

| Desiccant | Type | Uses | Advantages | Disadvantages |

| Silica gel | Synthetic | Electronics, pharmaceuticals, food packaging | High capacity, reusable | Can lose effectiveness over time |

| Montmorillonite clay | Natural | Food and pharmaceutical packaging | Natural, eco-friendly | Lower capacity than some desiccants |

| Molecular sieve | Synthetic | Petrochemical industries, air separation plants | Highly selective adsorption, good for low moisture environments | Not reusable for all applications |

| Activated alumina | Synthetic | Air and gas drying, water purification | High capacity, good for high temperatures | Can be corrosive to some materials |

| Calcium chloride | Inorganic salt | Large shipping containers, dehumidifiers | Very high capacity, absorbs moisture quickly | Not reusable, can be corrosive |

How Desiccants Work: Adsorption vs. Absorption

To understand how desiccants work it is necessary to explain the difference between adsorption and absorption. Adsorption is defined as the ability of water molecules to attach to the surface of the desiccant material and form a single layer of molecules called monolayer. This is the working principle of desiccants such as silica gel and activated alumina. These materials are porous and as such have a large surface area that enables them to absorb a large amount of water vapor from the surrounding atmosphere. Adsorption is usually a physical process. This means that it does not involve any chemical change in the desiccant material.

While in absorption, the water molecules are actually taken up into the internal structure of the desiccant material and this may cause a change of state or composition of the desiccant. For example, calcium chloride is hygroscopic in nature and it turns water vapor into liquid brine. This makes absorption a bulk phenomenon, in that the whole volume of the desiccant material is involved. Both adsorption and absorption have their own benefits and drawbacks and the selection between the two is based on the need of the application. Adsorption type desiccants are applied for the cases, when it is necessary to provide high-capacity and fast moisture removal in limited volume, while absorption type desiccants are suitable for the cases, when it is necessary to provide large amounts of moisture removal during a long period of time.

Uses of Desiccants

Commercial and Industrial Uses

Desiccants are widely used in the commercial and industrial fields to ensure product quality and smooth running of business. One of the most important fields where they are widely used is the field of protective packaging of various consumer goods such as electronics and drugs. Some of the delicate electronic parts are very much affected by moisture, which can lead to moisture damage, corrosion, and short-circuiting. Components such as microprocessors, capacitors, and other sensitive electronic parts are protected by desiccant packs, which include silica gel or molecular sieves to keep the humidity level in the packaging low and maintain a state of dryness. Likewise, in the pharmaceutical industry, desiccants act as drying agents to protect against moisture that could spoil the drugs and maintain their effectiveness and shelf stability. These desiccant materials are vital in the safe and efficient transport of medicines and medical devices because of the exact moisture control they provide. At the same time, desiccants are used in gas drying systems to eliminate water vapor from compressed air and gases. This is important in areas such as air separation plants where water has to be removed to avoid the formation of ice and plugging of cryogenic equipment. Molecular sieves, which are particularly useful in selectively adsorbing certain molecules, are often employed in such uses.

Residential and Everyday Applications

Desiccants are not only limited to industrial and commercial uses but are used in our everyday lives. In the home, desiccants are used in dehumidifiers to regulate humidity in areas such as the basement, closet, and other enclosed areas. These devices are often fitted with activated alumina or calcium chloride to absorb moisture that can cause mold and moldy smell. These household applications help in enhancing the quality of living in a home by minimizing the chances of mold related diseases and also in preserving the physical stability of the house.

Benefits of Using Desiccants

Another advantage of using desiccants is that they help in preventing rust and corrosion. Moisture is particularly damaging to metals due to the fact that it leads to oxidation and rusting. Silica gel and activated alumina are some of the most popular desiccants that are used in packing of metal products, machinery and electronic products to reduce the level of humidity. In this way, they shield these items from the effects of moisture, which can cause corrosion and reduce their life expectancy and performance. This is especially important in sectors such as automotive and aerospace, where failure of a component due to rusting can lead to disastrous outcomes.

Desiccants are important for maintaining the dryness of products and preventing them from getting spoiled by moisture. In the food packaging sector, desiccants play the role of preserving the quality of the products that are prone to getting spoiled easily. The use of desiccants in packaging helps to regulate relative humidity, thus inhibiting the formation of mold and bacteria, which can lead to spoilage of food products. This is especially important for things like spices, which can easily go rancid if they get wet. These products should reach the consumers in the best condition that is why desiccants are used to retain the taste and nutritional value of the products.

Choosing the Right Desiccant

Factors to Consider

Selecting the right desiccant requires the following important factors to be taken into consideration in order to achieve the best results in the removal of moisture. The first factor that needs to be taken into account is the nature of the product that is to be protected. For example, electronics and pharmaceuticals need desiccants with high adsorption capacity like silica gel or molecular sieves to keep the relative humidity very low. Another important consideration is the conditions under which the desiccant will be applied or used. In high humidity areas, more potent absorbing materials such as calcium chloride may be used since they can easily absorb large amounts of moisture.

Another factor that is very important in the selection of desiccant is the specific moisture control needs of the application. For instance, if the objective is to prevent moisture from damaging delicate items stored in small areas, then a large-capacity desiccant such as silica gel will be suitable. On the other hand, for large scale industrial uses, desiccants that can provide long term moisture protection like montmorillonite clay may be preferable. The type of desiccant to be used should also be determined based on the packaging and form factor such as packs, beads or canisters depending on how the desiccant will be used. Considering these factors makes it possible to select a right desiccant that will help to control moisture in the application in the best way possible.

Desiccant Testing

Pre-testing of the desiccant is important in a way that the chosen desiccant will effectively work in the planned application. This includes determining the amount of moisture that the desiccant can hold, how fast it absorbs the moisture and its efficiency under various conditions. For instance, testing can help find out the capacity of a desiccant to absorb moisture before it gets saturated and therefore needs to be replaced. This information is important for applications where the desiccant needs to be effective for a long time without the need for replacement.

Desiccant Shelf Life

Understanding Shelf Life

The shelf life of a desiccant is the time period for which it is capable of absorbing moisture as it was initially designed to do. It is important to understand the shelf life so that desiccants are ready to do their job when required. The shelf life of a desiccant depends on the type of desiccant and the storage conditions of the desiccant. For instance, silica gel packets can last for as long as six months to one year depending on the condition in which they are stored; in an airtight container, away from moisture. On the other hand, calcium chloride which has a higher tendency of absorbing moisture may have a shorter life span but it is highly efficient at the beginning.

Some of the conditions that may affect the life of a desiccant include exposure to ambient humidity and temperature. Some desiccants, even when hermetically packed, can gradually take up moisture from the environment, thus losing their efficiency before they are used. In most cases, manufacturers give recommendations on the shelf life of their products; however, it is crucial to inspect the state of stored desiccants from time to time. This way, the saturation or degradation of the desiccants can be detected early and only effective ones used for moisture control.

Storage Conditions and Maintenance for Longevity

The effectiveness of desiccants depends on the storage conditions that should be maintained properly. In an ideal world, desiccants should be stored in cool dry places to avoid early absorption of moisture. This means that high temperatures and humidity levels will enhance the absorption process and thereby shorten the shelf life of the desiccant. Hence, it is necessary to preserve desiccants in appropriate conditions, in particular, in places where they are protected from direct sunlight and moisture.

It is also important to note that proper care and checkups are also crucial in the preservation of desiccants. Desiccants should be checked from time to time for signs of saturation, including clumping or discoloration, in case they are stored. Desiccants that are saturated should be replaced as soon as possible so that they do not hinder moisture control. Adopting a systematic rotation schedule can also assist in minimizing the use of old stock and therefore minimize the use of ineffective desiccants. Desiccants should be stored properly and their use should be preceded by proper maintenance measures to ensure that they can effectively protect the items against moisture for as long as possible.

Regenerating Desiccants

Techniques and Methods

Some desiccats have the additional feature of being reusable, that is, they can be regenerated or reactivated after they have been used. Regeneration normally entails heating the desiccant to a certain temperature to free the moisture that was absorbed. For instance, silica gel can be regenerated by heating it in an oven at temperature of 120-150°C for several hours. This process removes the water molecules that were previously locked in the desiccant and thus regenerates the desiccant.

Some desiccants may need to be regenerated in a particular way depending on the type of desiccant used. For example, activated alumina can be regenerated by heating it in the same manner as zeolites, while molecular sieves need higher temperatures for regeneration. Manufacturers’ instructions must be strictly adhered to in order to avoid damaging the desiccant material during regeneration. However, some of the desiccants may alter color when they get wet, and this will be an indication that they need to be regenerated.

Pros and Cons of Regeneration

Regenerating desiccants has some advantages such as; it is cheaper to use and it is environmentally friendly. This is because, by reusing desiccants, you can reduce on wastage and hence the cost of moisture control. This is especially the case in industries where large quantities of desiccants are used frequently. Regeneration also has the added benefit of decreasing the impact of the disposal of used desiccants and the manufacturing of new ones on the environment.

However, there are also some drawbacks that should be taken into consideration. Not all desiccants can be regenerated; for example, calcium chloride which turns into a liquid brine when it has absorbed moisture cannot be regenerated. Also, the regeneration process may sometimes have an impact on the efficiency of desiccants in the process. Prolonged heating may lead to changes in the structure or even the degradation of the material, thus reducing the desiccant’s ability to absorb moisture. Hence, cost and environmental advantages of regeneration should be weighed against the possible reduction in performance, while making sure that the regenerated desiccants will still effectively manage moisture.

Environmental Considerations: Natural vs. Manufactured Desiccants

When it comes to the selection of natural and manufactured desiccants, environmental factors are always taken into consideration. Montmorillonite clay and selected plant materials are some of the natural desiccants that are environmentally friendly than synthetic ones. These natural desiccants are eco-friendly and have a lesser impact on the environment and thus can be used where sustainability is a concern. For instance, montmorillonite clay is commonly used in food packaging because of its natural origin and moisture absorbing capacity. Its use is useful in helping companies achieve sustainability objectives while offering dependable barrier against moisture intrusion.

Manufactured desiccants on the other hand include silica gel and molecular sieves which are produced through a manufacturing process. Although they are not as eco-friendly as natural desiccants, they tend to be much more effective in terms of moisture adsorption and desiccant life. For instance, silica gel can be reused several times after heating, thus, the frequency of replacement is low and the amount of waste produced is also low. Molecular sieves are characterized by well-defined pore structures and are used in industries requiring high levels of moisture control. The decision between natural and manufactured desiccants is based on the application need and the sustainability and environmental factors.

Conclusion

It is crucial to grasp the fundamentals of a desiccant and its operation to achieve the best results in various applications. Desiccants are not merely anti-moisture packets, but valuable assets that help in product safety, performance, and even the preservation of the environment. Whether you are a consumer seeking to preserve spices or an industrialist seeking to preserve delicate equipment, the right desiccant is the way to go.