There are two main types of zeolite molecular sieves for oxygen concentrator in market, sodium type and lithium type molecular sieve. The lithium type zeolite molecular sieves are more efficient than sodium type zeolite molecular sieves that can greatly reduce the volume of oxygen generators that makes the oxygen concentrator smaller and easier to carry around. Since the lithium molecular sieve is much more expensive than sodium type, sodium oxygen molecular sieve is also very popular in the market for most cases.

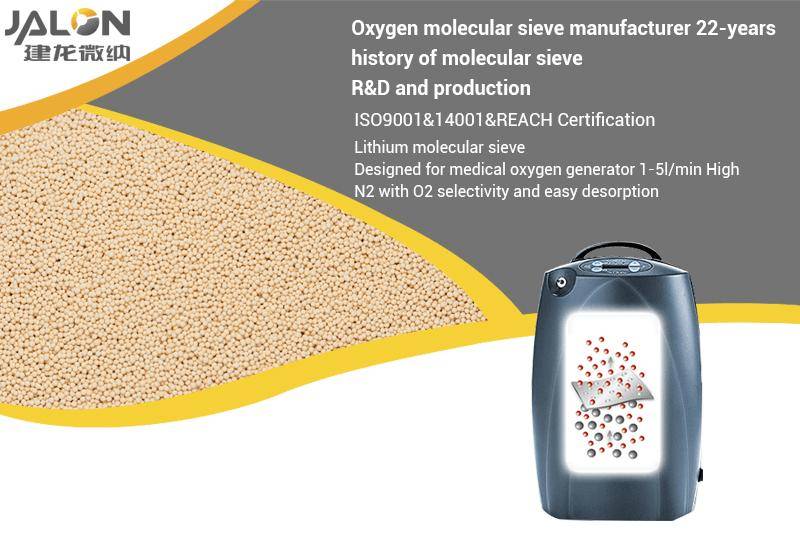

JALON is a professional molecular sieve manufacturer for oxygen generators Among our products, JLOX-501A is a sodium-type molecular sieve and JLOX-101A is a lithium molecular sieve. The comparison of the application parameters of sodium molecular sieve and lithium molecular sieve is as follows:

| Parameters | JLOX-101A | JLOX-501A |

| Size | 0.4-0.8mm | 0.4-0.8mm |

| Applicable Machines | 1-20 L/min | 1-5L/min |

| Oxygen Concentration | 93±3% | 93±3% |

| Adsorption Pressure | 1.0-2.0 bar | 1.4-2.0 bar |

| Package | 25kg 125kg steel drum | 25kg 125kg steel drum |

Molecular sieve JLOX-101A and JLOX-501A adsorbents are patented products specially designed for use in medical oxygen concentrators that employ a pressure swing cycle to generate high purity oxygen.

JLOX-501A is recommended to use in portable oxygen concentrators of 1-5/L min and J LOX-101A is recommended to use portable oxygen concentrator that required of with smaller size, JLOX-101A has the N2/O2 selectivity around 2 times higher and 2.75 times higher of static N2 adsorption capacity than JLOX-1501A.

Both JLOX-101A and JLOX-501A have a high nitrogen capacity and superior nitrogen/oxygen selectivity compared to equivalent products in the market that result in the use of significantly less material relative to other molecular sieve adsorbents without sacrificing oxygen throughput or purity.

PSA (pressure swing adsorption) and VPSA (vacuum pressure swing adsorption) technologies are two commonly used methods for oxygen production. Both methods use zeolite molecular sieves. By pressure swing, the nitrogen and oxygen in the air are separated through adsorption and desorption processes to obtain high-purity oxygen. Because argon in the air has similar properties with oxygen, it is difficult to be separated from oxygen by zeolite molecular sieve, so the purity of oxygen obtained is <96% maximum.

Compared with VPSA oxygen production equipment, PSA equipment has lower initial investment, but high energy consumption and high maintenance cost in the later operation. When the oxygen demand is greater, there is no longer any economic advantage due to the large area of PSA equipment and high energy consumption.

The sodium-based molecular sieve JLOX-500, calcium-based JLOX-200A and lithium-based molecular sieve JLOX-103 produced by LUOYANG JALON are specially designed for PSA, VPSA and VPSA oxygen production and VPSA oxygen production respectively. Both of these two products have large

adsorption capacity, good N2/O2 selectivity, high crush strength and good dynamic adsorption performance. Since entering the market in 2010, it has been widely used, and its quality and performance have been tested by the market. The following are some parameters of the two types of oxygen zeolite for oxygen concentrator to your reference:

| Molecular Sieve | JLOX-103 | JLOX-500 |

| Type | Lithium X | Sodium X |

| Applicable Machine | VPSA | PSA |

| Product gas capacity (Nm3/hour) | 300-10000 | 1-300 |

| Adsorption Pressure | 40~50 KPa | 6-8 Bar |

Oxygen zeolite molecular sieve will preferentially adsorb water over all other airborne molecules. To ensure maximum nitrogen capacity, moisture pick-up from air exposure should be minimized. Adsorbed water can’t be readily removed via pressure or vacuum swing purging.