Portable medical oxygen concentrators sieve bed material using molecular sieve as adsorbent, by pressure swing adsorption (pressure swing adsorption, PSA) in ambient air as raw material, under the condition of normal temperature low pressure, when using molecular sieve pressure of nitrogen in the air (adsorbate) adsorption capacity increases, the decompression of the characteristics of the nitrogen adsorption capacity to reduce in the air, forming pressure adsorption pressure desorption process of rapid cycling to separating oxygen and nitrogen in the air, resulting in a high concentration of oxygen.

Read More >

Cryogenic air separation plays a key role in producing oxygen, nitrogen, and argon by separating contaminants such as carbon dioxide and water from a gas stream.

Our rapid absorption solution can satisfy the wide needs of air separation across numerous industrial production.

Read More >

JL-COS adsorbent is sensitive to oxygen, carbon dioxide, water vapor and sulfur-containing gas.

Compared with ordinary molecular sieves, high-efficiency CO adsorbents have stronger selectivity for CO and larger adsorption capacity (can increase by about 60%).

Read More >

Ethanol Dehydration Grade Molecular Sieve have lower its water content, the higher quality of alcohol is produced. However, using typical multi-pressure distillation processes alone, the ethanol to water azeotopic ratio is at 95.5%, with a maximum of 97.2%. Further purification is needed to exceed the limits for a more refined final product.

Read More >

Moisture is one of the primary challenges in the polyurethane industry since the material readily absorbs water from the air and create gaseous carbon with the isocyanate constituent. The Carbon Dioxide gases can create undesirable effects such as air bubbles on polyurethane coating, which significantly decreases the shelf life of the product.

Read More >

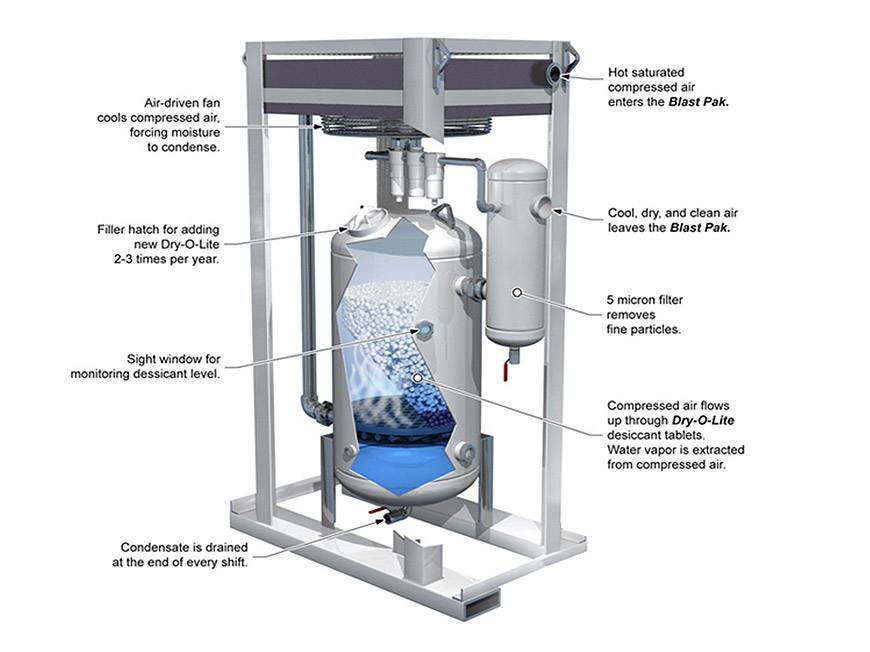

As a process, air drying takes away the moisture from the air, keeping the machinery and equipment running uninterrupted.

This is an energy-efficient and cost-effective method of maintaining moisture levels within the area, which can help reduce production and maintenance costs.

Read More >

PX belongs to a kind of C8 mixed aromatics, which has 4 isomers, namely OX(ortho-xylene), MX(meta-xylene), PX(para-xylene), and EB(ethylbenzene). Limited by the thermodynamic balance, the OX content takes a large portion of C8 mixed aromatics at 41%-45%, while the PX content, which has the largest industrial demand, takes only about 20%. Many world-scale projects are being configured to produce maximum volumes of chemicals. In order to maximize the production of PX, technologies such as toluene disproportionation, trans-alkylation, and isomerization are usually used in industry to increase the production of PX.

Read More >

JLOX-103 oxygen enrichment sieve bed is the lithium form aluminosilicate with X type crystal structure. lithium based high performance oxygen enrichment sieve bed;designed for industrial VPSA oxygen plant,Capacily: 300 -10000 Nm3/hour, oxygen purity is up to 93%±3%

Read More >

This letter is to inform you that we evaluated Molecular Sieve JLOED 3.0-5.0 MM product from Luoyang Jalon Micro-nano New Materials Co., Ltd to dry our organic solvents for production of electrolyte for Li ion battery. The resulting organic solvents that went through our process with the Molecular Sieve JLOED 3.0-5.0 MM product in our R/D and production facility located in Chico, CA, US passed our specifications showing extremely low content of moisture, below 10ppm. This Molecular Sieve product met our quality requirement, and it is highly recommended for use in the industry of Li ion battery for drying of organic solvents. We also appreciate the technical support from the company.

Nanotech Energy

Luoyang Jalon Micro-nano New Materials Co., Ltd. JLPM series molecular sieves are mainly used for cryogenic drying of general industrial gases. The purification system in the air separation unit removes H2O and CO2, as well as natural gas and other hydrocarbon desulfurization (removal of H2S and mercaptans) and CO2.

It is worth mentioning that Yuntianhua United Commerce Co., Ltd. Company 52000 Nm3/Cryogenic air separation unit project. The design and manufacture method of the air separation unit by air, adsorber adopt vertical radial flow design, processing capacity of 311352 nm3 / h, 5.13 Bar (A) adsorption pressure, loading type my company JLPM3 efficient molecular sieve 92 tons, 107 tons of activated alumina, can ensure that the CO2 content in the air mean 1000 parts per million (2000 PPM) instantaneous equipment and stable operation, export CO2 molecular sieve < 0.1 PPM.

The fifth-generation high-performance molecular sieve JLPM1 is an advanced molecular sieve used in the pre-purification unit (APPU) of air separation equipment. Compared with previous generations, the fifth-generation high-performance molecular sieve JLPM1 has significantly improved CO2 adsorption capacity; the fifth-generation high-performance molecular sieve JLPM1 will bring multiple benefits to air separation designers and operators. For the design of the new air separation plant, the application of the fifth-generation high-performance molecular sieve JLPM1 can make the air separation occupy a smaller area, thereby reducing equipment investment and operating costs. The fifth-generation high-performance molecular sieve JLPM1 can also be used for the transformation of old equipment, which can reduce energy consumption or improveair separation processing capacity.

Oxygen molecular sieve is an important material to ensure the work of VPSA oxygen production equipment. This project is another successful case of our JLOX-103 lithium-type high-efficiency oxygen molecular sieve.

The 30000Nm3/h pressure swing adsorption (VPSA) oxygen production project of Zhuhai Yueyufeng Iron and Steel Co., Ltd., designed and built by CSSC Huanggang Precious Metals Co., Ltd., was successfully started up on June 27, 2019. As of May 29, 2020, the device has been operating stably for 11 months, and all indicators are better than the design indicators. It has been highly recognized and praised by customers, and has created a cumulative effect of 150 million yuan per year for the enterprise. At the same time, the project has realized intelligent oxygen production, mobile control and remote monitoring to guide production, helping to realize the green and intelligent promotion of the industry.

The project uses 4 sets of pressure swing adsorption (VPSA) oxygen generators in parallel. The single set of device is designed to produce 7500Nm3/h of oxygen and 80% oxygen purity. It is filled with our company (Luoyang Jalon Micro Nano New Materials Co., Ltd.) JLOX-103 lithium-type high-efficiency oxygen molecular sieve is 68 tons, the actual oxygen output reaches 7650Nm3/h, and the oxygen concentration is above 82.3%. The 4 sets of equipment in this project are filled with 272 tons of our JLOX-103 oxygen molecular sieve, with a total oxygen production of more than 30000Nm3/h.

Oxygen molecular sieve is an important material to ensure the operation of VPSA oxygen production equipment. This project is another successful case of our company’s JLOX-103 lithium-type high-efficiency oxygen molecular sieve.

Luoyang Jalon Micro-nano New Materials Co., Ltd. JLOX-100 series high-efficiency oxygen generation molecular sieve is a lithium X-type aluminosilicate crystal, which is an oxygen generation molecular sieve with international advanced level. Widely used in: iron and steel, non-ferrous metallurgy, chemical industry, furnace energy-saving transformation, environmental protection, papermaking, aquaculture, medical care and other industries.